A method for preparing a high-voltage cathode material by using a waste lithium cobalt oxide battery

A positive electrode material, old lithium cobalt oxide technology, applied in the field of waste lithium-ion battery recycling and reuse, can solve the problems of inactive materials, insignificant product value-added, and insignificant value-added, and achieve high structural stability and efficient green restoration And value-added utilization, the effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

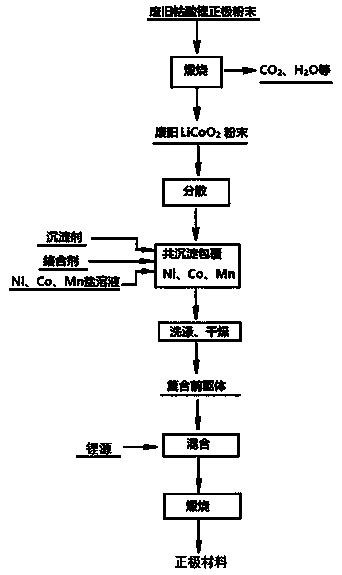

[0027] A method for preparing high-voltage positive electrode materials using waste lithium cobalt oxide batteries, such as figure 1 Shown, specifically include the following steps:

[0028] (1) Put the waste lithium cobalt oxide battery in 2mol / L sodium sulfate solution to discharge the remaining electricity, discharge for 24 hours, separate the positive electrode piece, and place it in a 6% sodium hydroxide solution by mass percentage, stir React for 12 hours, wash and filter the filter residue to become waste cathode material; calcinate the obtained filter residue at 600°C for 2 hours in an atmosphere furnace to obtain waste LiCoO 2 For powder materials, detect the percentage content of cobalt and lithium (Co, Li);

[0029] (2) According to the lithium-rich manganese-based solid solution The stoichiometric ratio, take nickel sulfate, cobalt sulfate and manganese sulfate, be mixed with the mixed salt solution of nickel salt, cobalt salt, manganese salt, the concentration ...

Embodiment 2

[0034] A kind of method adopting waste and old lithium cobalt oxide battery to prepare high-voltage cathode material, specifically comprises the following steps:

[0035] (1) Put the waste lithium cobalt oxide battery in 2mol / L sodium sulfate solution to discharge the remaining electricity, discharge for 24 hours, separate the positive electrode piece, and place it in a 6% sodium hydroxide solution by mass percentage, stir React for 12 hours, wash and filter the filter residue to become waste cathode material; calcinate the obtained filter residue at 600°C for 2 hours in an atmosphere furnace to obtain waste LiCoO 2 For powder materials, detect the percentage content of cobalt and lithium (Co, Li);

[0036] (2) According to the lithium-rich manganese-based solid solution stoichiometric ratio, take nickel chloride, cobalt chloride and manganese chloride, be mixed with the mixed salt solution of nickel salt, cobalt salt, manganese salt, the concentration sum of Ni+Co+Mn in the...

Embodiment 3

[0041] A kind of method adopting waste and old lithium cobalt oxide battery to prepare high-voltage cathode material, specifically comprises the following steps:

[0042] (1) Put the waste lithium cobalt oxide battery in 2mol / L sodium sulfate solution to discharge the remaining electricity, discharge for 24 hours, separate the positive electrode piece, and place it in a 6% sodium hydroxide solution by mass percentage, stir React for 12 hours, wash and filter the filter residue to become waste cathode material; calcinate the obtained filter residue at 600°C for 2 hours in an atmosphere furnace to obtain waste LiCoO 2 For powder materials, detect the percentage content of cobalt and lithium (Co, Li);

[0043] (2) According to the lithium-rich manganese-based solid solution The stoichiometric ratio, take nickel nitrate, cobalt nitrate and manganese nitrate, be mixed with the mixed salt solution of nickel salt, cobalt salt, manganese salt, the concentration sum of Ni+Co+Mn in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com