Graphene plated metal yarn for radar stealth and manufacturing method thereof

A radar stealth and graphene technology, applied in the direction of yarn, textiles and papermaking, etc., can solve the problems of low stealth efficiency, poor wearability, poor environmental resistance, etc., and achieve good heat preservation effect, good bonding strength, and good water resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

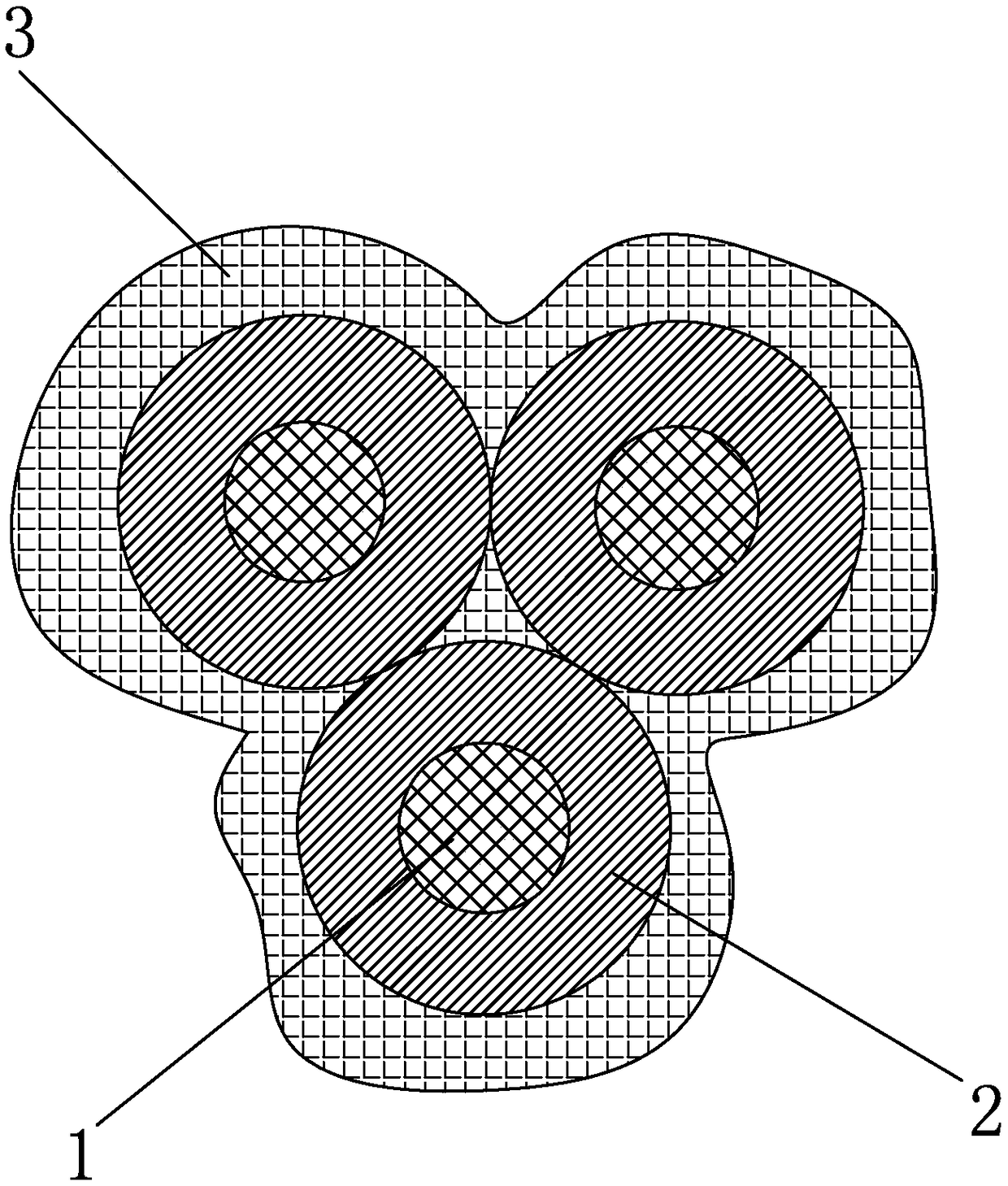

[0028] A graphene-coated metal yarn for radar stealth, comprising a metal yarn body and a graphene layer 3. The metal yarn body is a core-spun yarn including a core yarn and wrapping fibers. The core yarn is a hollow polyester filament 2 . The wrapping fibers are silver-plated wires 1 . The structure of the core-spun yarn can effectively improve the moisture permeability, flexibility and warmth retention of the metal yarn body, and ensure the spinnability of the yarn and the wearability of the textile fabric. The silver-plated metal wire 1 is coated with a metal silver layer on the surface of the matrix filament, and has the characteristics of lower cost, better flexibility and better wrinkle recovery than pure metal wire. The thickness of the metallic silver layer is controlled at 5-10 μm. In order to improve the strength of the metal yarn body and ensure the bonding strength of the graphene layer 3, the metal yarn body is 2-8, twisted and plyed to form a twisted yarn. Pr...

Embodiment 2

[0035] The radar stealth with structure identical with embodiment 1 is coated with metal yarn with graphene, for the preparation method of this radar stealth with graphene coated with metal yarn, may further comprise the steps:

[0036] In step 1, the metal yarn body is parallel-twisted by a twisting machine to form a twisted yarn.

[0037] Step 2, add graphite powder to the well-stirred concentrated sulfuric acid and sodium nitrate solution, then add potassium permanganate, stir for 30-50 minutes, let stand for stratification, remove the lower layer, add 30% hydrogen peroxide solution, and react , and then pickled, washed with water, sonicated for 2 hours, and then centrifuged to obtain graphene oxide, which was prepared into a 10 g / L graphene oxide solution. The twisted yarn was processed by a sizing machine, the graphene oxide solution was put into the immersion tank, the speed of the sizing machine was 6r / min, and the temperature in the drying zone was 60°C; the twisted ya...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com