Highly anti-corrosion chemical nickel-plating liquid and preparation method thereof

An electroless nickel plating solution and high corrosion resistance technology, which is applied in liquid chemical plating, metal material coating process, coating, etc., can solve the problems of poor anti-corrosion performance, unstable plating solution, and slow deposition speed, etc. Achieve the effects of fine and bright coating crystallization, improved protection performance, and low porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

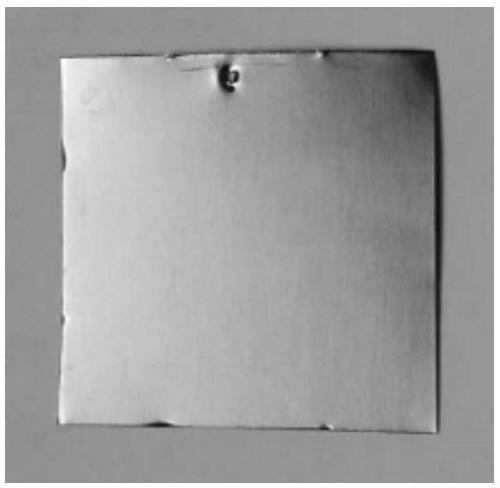

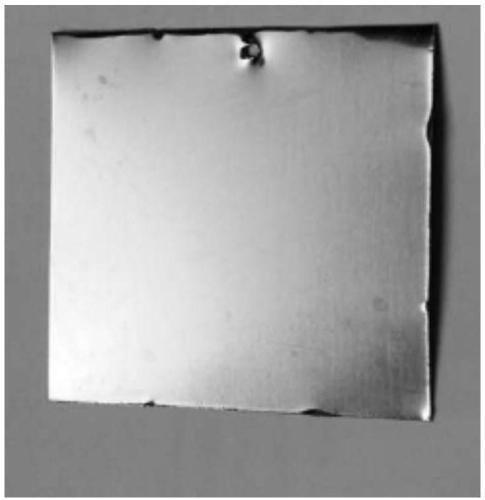

Image

Examples

Embodiment 1

[0030] The highly corrosion-resistant electroless nickel plating solution of this embodiment includes the following components: chemical nickel base solution, wetting agent, brightener, and stabilizer.

[0031] Wherein: the chemical nickel base liquid is nickel sulfate 25g / L, sodium hypophosphite 30g / L, citric acid 15g / L, lactic acid 10g / L, propionic acid 5g / L, sodium acetate 10g / L; the wetting agent It is polyethylene glycol (M=6000) 0.02g / L; the brightener is 2-mercaptobenzothiazole 5mg / L, polyalkyleneimine (M=5000) 1mg / L; the stabilizer is S- Carboxyethylisothiouronium salt 5mg / L; The preparation method of the high corrosion resistance chemical nickel plating solution of the present embodiment, comprises the steps:

[0032] (1) Use deionized water to prepare the base liquid, first mix and dissolve quantitative nickel sulfate with citric acid, lactic acid and propionic acid, and finally add quantitative sodium acetate and sodium hypophosphite, and fully stir;

[0033] (2) A...

Embodiment 2

[0052] The highly corrosion-resistant electroless nickel plating solution of this embodiment includes the following components: chemical nickel base solution, wetting agent, brightener, and stabilizer.

[0053] Wherein: the chemical nickel base liquid is nickel sulfate 25g / L, sodium hypophosphite 30g / L, citric acid 15g / L, lactic acid 10g / L, propionic acid 5g / L, sodium acetate 10g / L; the wetting agent It is polyethylene glycol (M=6000) 0.02g / L; the brightener is 2-mercaptobenzothiazole 5mg / L, polyalkyleneimine (M=5000) 1mg / L; the stabilizer is 3- Sulfur-isothiourea propane sulfonic acid compound 5mg / L; The preparation method of the high corrosion resistance electroless nickel plating solution of the present embodiment, comprises the steps:

[0054] (1) Use deionized water to prepare the base liquid, first mix and dissolve quantitative nickel sulfate with citric acid, lactic acid, and propionic acid, and finally add quantitative sodium acetate and sodium hypophosphite, and fully...

Embodiment 3

[0070] The highly corrosion-resistant electroless nickel plating solution of this embodiment includes the following components: chemical nickel base solution, wetting agent, brightener, and stabilizer.

[0071] Wherein: the chemical nickel base liquid is nickel sulfate 25g / L, sodium hypophosphite 30g / L, citric acid 15g / L, lactic acid 10g / L, propionic acid 5g / L, sodium acetate 10g / L; the wetting agent It is polyethylene glycol (M=6000) 0.02g / L; the brightener is 2-mercaptobenzothiazole 5mg / L, polyalkyleneimine (M=5000) 1mg / L; the stabilizer is 3- Amino-5-mercapto-1,2,4-triazole 5mg / L; The preparation method of the high corrosion resistance electroless nickel plating solution of the present embodiment comprises the steps:

[0072] (1) Use deionized water to prepare the base liquid, first mix and dissolve quantitative nickel sulfate with citric acid, lactic acid and propionic acid, and finally add quantitative sodium acetate and sodium hypophosphite, and fully stir;

[0073] (2)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com