Water-based casting coating for coated sand casting and preparation method thereof

A casting coating and coated sand technology, which is applied to casting molding equipment, coatings, casting molds, etc., can solve the problems of difficult to improve casting surface quality and poor casting surface quality, and achieve smooth casting surface, simple manufacturing process, The effect of low roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

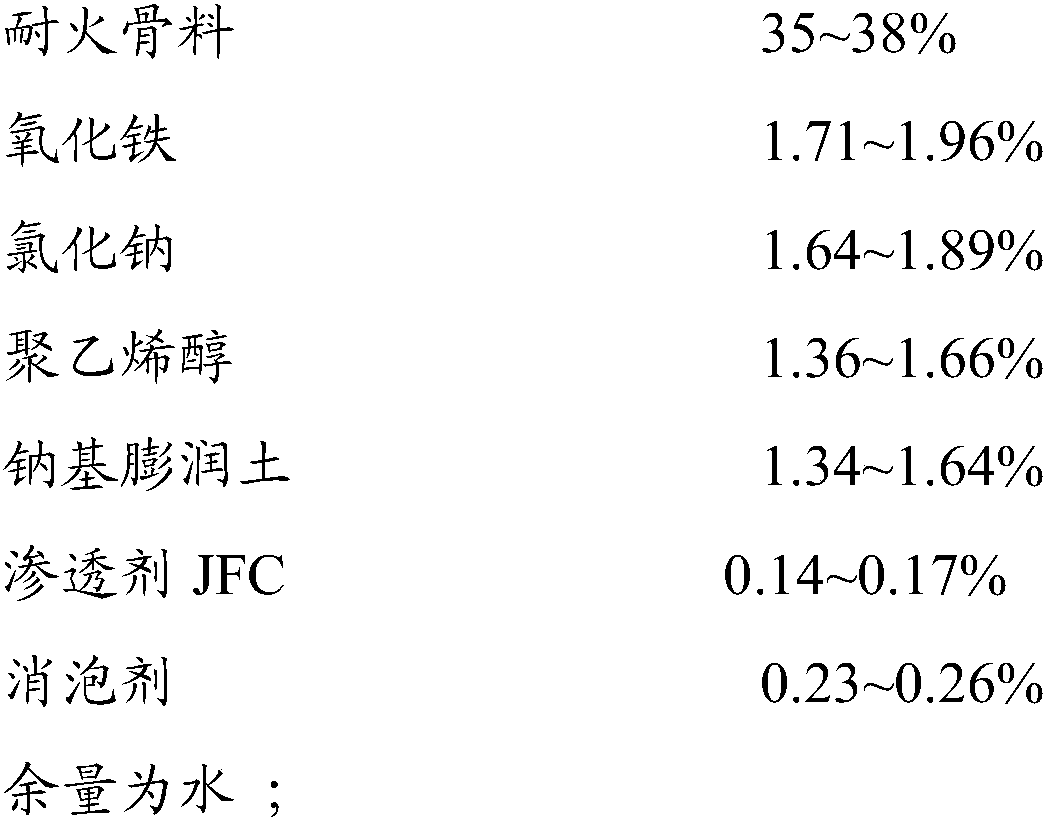

[0025] The weight percent of the water-based foundry coating formula composition that this implementation is used for coated sand casting is: particle size is 600 mesh pyrophyllite powder 36%, particle size is 800 mesh iron oxide 1.84%, sodium chloride 1.76%, polyvinyl alcohol 1.43% %, sodium bentonite 1.57%, penetrant JFC 0.15%, n-amyl alcohol 0.25%, water 57%. Prepare coating gross weight 1000 grams, concrete preparation steps are as follows:

[0026] (1) Weigh 360 grams of pyrophyllite powder, 18.4 grams of iron oxide powder, 17.6 grams of sodium chloride, 1.5 grams of penetrant JFC, 2.5 grams of defoamer, 15.7 grams of sodium bentonite, and 14.3 grams of polyvinyl alcohol by weight percentage and water 570 grams;

[0027] (2) 15.7 grams of sodium bentonite and 15.7 grams of water are mixed to make a paste for subsequent use;

[0028] (3) Take 128.7 grams of water and put it into a small container, then slowly add 14.3 grams of polyvinyl alcohol therein, stir while adding...

Embodiment 2

[0034] The weight percent of the water-based foundry coating formula composition that this implementation is used for coated sand casting is: particle size is 700 mesh kaolin 35%, particle size is 700 mesh iron oxide 1.71%, industrial grade sodium chloride 1.89%, cold water instant polymer Vinyl alcohol 1.66%, sodium bentonite 1.34%, penetrant JFC 0.17%, n-butanol 0.23%, water 58%. The total weight of the coating is 1000 grams, and the specific manufacturing steps are as follows:

[0035] (1) Weigh 350 grams of kaolin, 17.1 grams of iron oxide powder, 18.9 grams of industrial grade sodium chloride, 1.7 grams of penetrant JFC, 2.3 grams of n-butanol, 13.4 grams of sodium bentonite, and 16.6 grams of cold water instant polyvinyl alcohol. grams and 580g of water;

[0036] (2) 13.4 grams of sodium bentonite and 13.4 grams of water are mixed to make a paste for subsequent use;

[0037] (3) Take 149.4 grams of water and put it into a small container, then slowly add 16.6 grams of ...

Embodiment 3

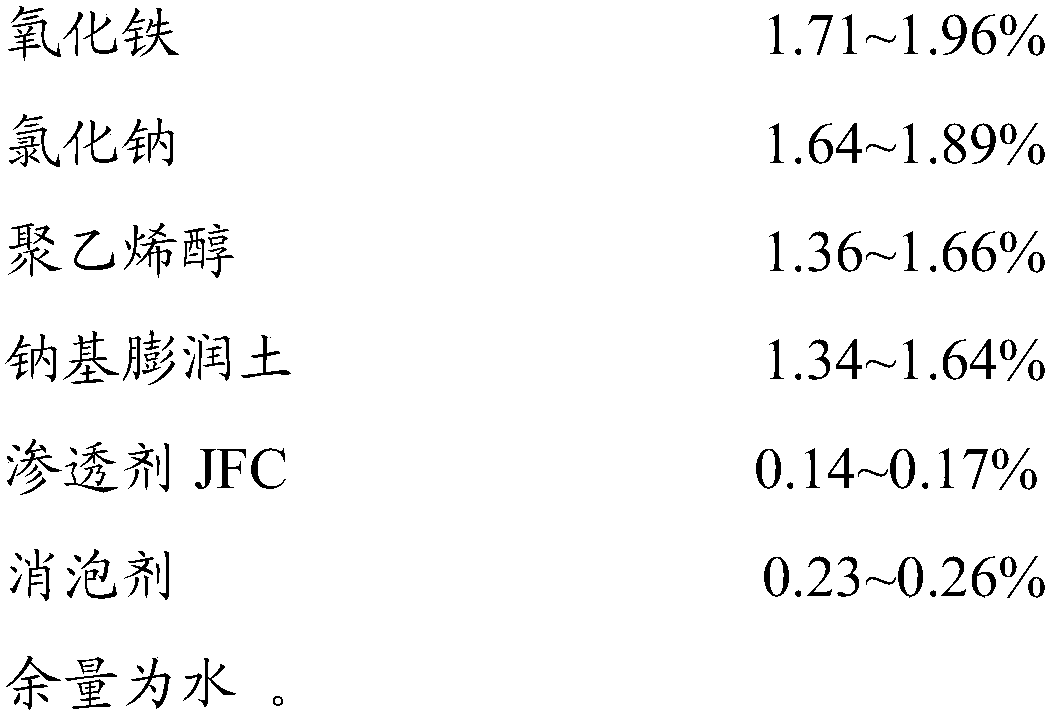

[0043] The weight percent of the water-based foundry paint formula composition for coated sand casting in this implementation is: 38% of quartz powder with a particle size of 800 mesh, 1.96% of iron oxide with a particle size of 600 mesh, 1.64% of industrial grade sodium chloride, cold water instant type Polyvinyl alcohol 1.36%, sodium bentonite 1.64%, penetrant JFC 0.14%, n-octanol 0.26%, water 55%. The total weight of the coating is 1000 grams, and the specific manufacturing steps are as follows:

[0044] (1) Weigh 380 grams of kaolin, 19.6 grams of iron oxide powder, 16.4 grams of industrial grade sodium chloride, 1.4 grams of penetrant JFC, 2.6 grams of n-butanol, 16.4 grams of sodium bentonite, and 13.6 grams of cold water instant polyvinyl alcohol. grams and 550g of water;

[0045] (2) 16.4 grams of sodium bentonite and 16.4 grams of water are mixed to make a paste for subsequent use;

[0046] (3) Take 122.4 grams of water and put it into a small container, then slowly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com