Preparation method of copper alloy powder for manufacturing of additional materials

An additive manufacturing and copper alloy technology, applied in additive processing, metal processing equipment, transportation and packaging, etc., can solve the problems of copper alloy powder sphericity, poor fluidity and purity, and achieve excellent fluidity and composition. The effect of uniform tissue and low oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

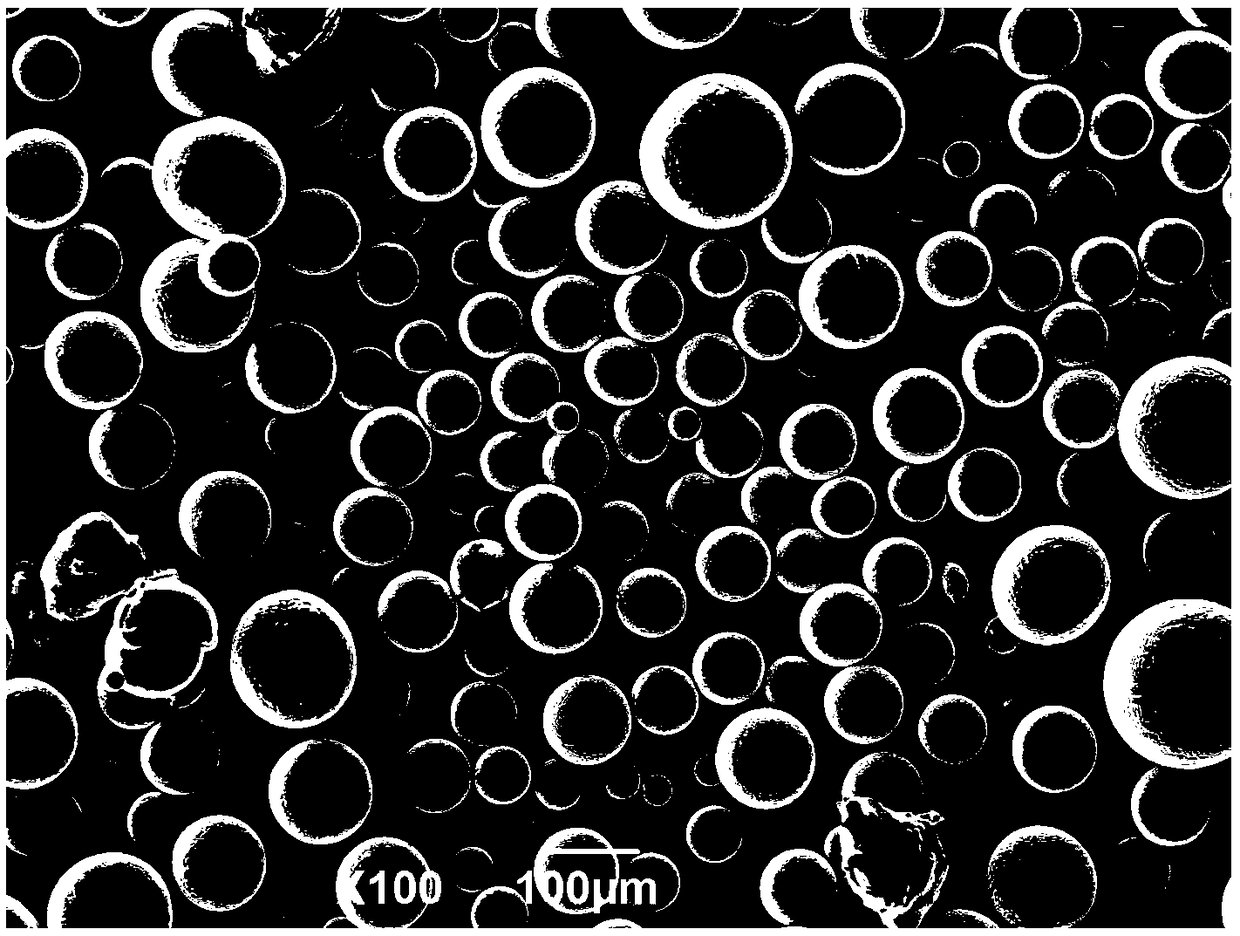

Image

Examples

preparation example Construction

[0029] A kind of preparation method of copper alloy powder for additive manufacturing of the present invention is specifically implemented according to the following steps:

[0030] Step 1, according to the composition of the copper alloy, the ingredients are: Cu matrix 96-99.99wt%, adding 0-3wt% of Ag, Cr, W, Ni alloy elements, Zr 0.01-1wt%, the sum of the mass percentages of the above components is 100 %;

[0031] Step 2, placing the Cu matrix and alloy elements in step 1 in a vacuum induction melting furnace for melting, and using electromagnetic stirring, and then keeping the temperature at 1300°C-1500°C for 2min-8min to obtain a copper alloy mixture;

[0032] The melting temperature is 1000℃~1300℃, the melting time is 0.5h~10h, and the vacuum degree of the vacuum induction melting furnace is 5×10 -3 Pa~9×10 -2 Pa;

[0033] Step 3, preparing copper alloy ingot;

[0034] Specifically: put the copper alloy mixture obtained after step 2 into the crystallizer for casting, ...

Embodiment 1

[0056] A kind of preparation method of copper alloy powder for additive manufacturing of the present invention is specifically implemented according to the following steps:

[0057] Step 1, according to the ingredients of the copper alloy: Cu matrix 96wt%, adding 3wt% Ag element, Zr 1wt%, the sum of the mass percentages of the above components is 100%;

[0058] Step 2, putting the Cu matrix and the Ag element in the step 1 into a vacuum induction melting furnace for melting, and using electromagnetic stirring, and then keeping the temperature at 1300° C. for 2 minutes to obtain a copper alloy mixture;

[0059] The melting temperature is 1000°C, the melting time is 0.5h, and the vacuum degree of the vacuum induction melting furnace is 5×10 -3 Pa;

[0060] Step 3, preparing copper alloy ingot;

[0061] Specifically: the copper alloy mixture obtained after step 2 is placed in a crystallizer for casting, stirred by an electromagnetic stirrer, and cooling water is introduced into...

Embodiment 2

[0075] A kind of preparation method of copper alloy powder for additive manufacturing of the present invention is specifically implemented according to the following steps:

[0076] Step 1, according to the composition of the copper alloy as ingredients: Cu matrix 97wt%, Cr 2.5wt%, Zr0.5wt%, the sum of the mass percentages of the above components is 100%;

[0077] Step 2, placing the Cu matrix and Cr in step 1 in a vacuum induction melting furnace for melting, and using electromagnetic stirring, and then keeping the temperature at 1450° C. for 5 minutes to obtain a copper alloy mixture;

[0078] The melting temperature is 1100°C, the melting time is 1h, and the vacuum degree of the vacuum induction melting furnace is 6×10 -3 Pa;

[0079] Step 3, preparing copper alloy ingot;

[0080] Specifically: put the copper alloy mixture obtained after step 2 into the crystallizer for casting, use an electromagnetic stirrer to stir, and feed cooling water into the crystallizer, and at t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com