Methanation system and method for preparing natural gas from coke-oven gas

A coke oven gas and methanation technology, applied in chemical instruments and methods, gas fuels, chemical/physical processes, etc., can solve the problems of difficult process amplification and increased equipment investment, and achieve high operational safety and energy saving , the effect of uniform temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

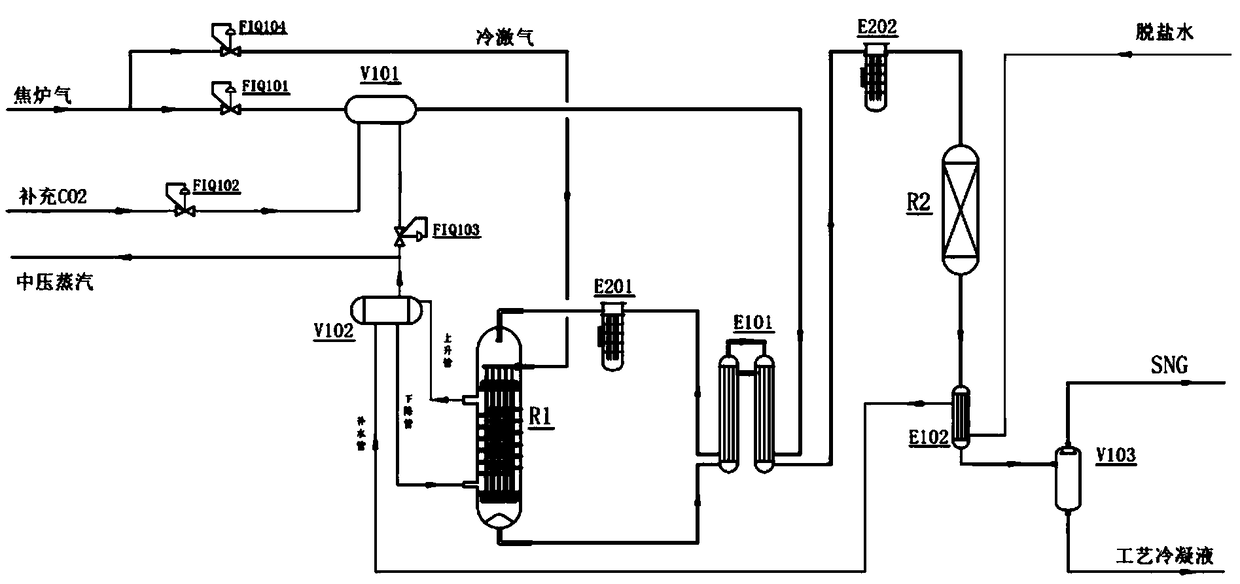

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0029] A methanation method of coke oven gas to natural gas, the flow rate of coke oven gas from the system is 4000Nm 3 / h, pressure 9.0MPa, supplemented with CO 2 Airflow 1000Nm 3 / h, add water vapor 500Nm 3 / h, the three-way gas is passed into the gas mixing tank V101 and mixed evenly to form a raw material gas of 5500Nm into the tower 3 / h, the temperature reaches 220°C after heat exchange through the first tube heat exchanger E101, and then heated to 305°C by the first electric heater E201, and then passed into the upper part of the uniform temperature methanation reactor R1, and the The methanation catalyst catalyzes the reaction;

[0030] The other path of the coke oven gas is used as the chilled gas at a temperature of 20°C, and the flow rate is adjusted to 4000Nm by the chilled gas flow regulating valve FIQ104 3 / h, from the ventilation hole on the cold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com