Mesoporous carbon prepared by using manganese compound, and preparation method thereof

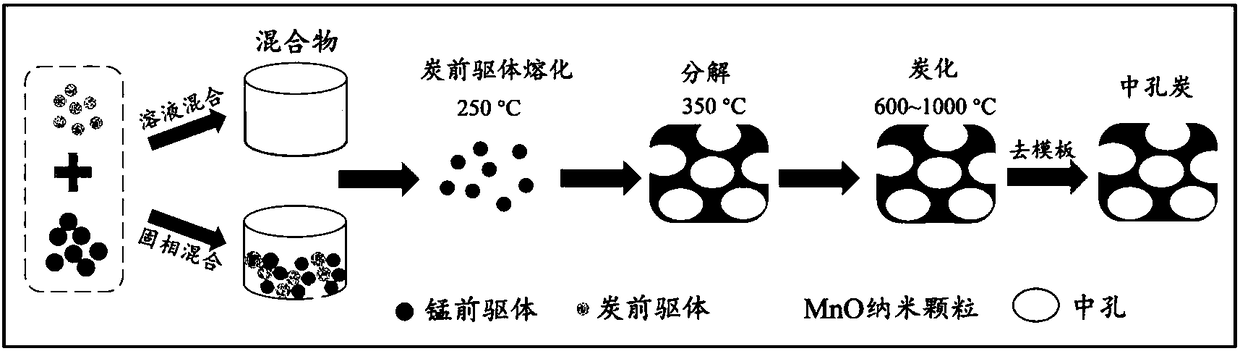

A technology of manganese compounds and porous carbon, which is applied in the fields of manganese compounds, chemical instruments and methods, carbon preparation/purification, etc., can solve problems such as difficulty in achieving precise control of pore structure, inability to regenerate soft templates, and restricting the application of soft template methods. , to achieve the effect of high mesoporosity, low cost and reduced preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Grind the PVA solid particles to 200 mesh. The obtained PVA powder and manganese carbonate are uniformly mixed mechanically in a ratio of 1:1 (the mass ratio of PVA to MnO). Weigh a certain mass of mixed sample in a quartz tube furnace, 2 Carbonize the sample in the atmosphere. The heating rate is 5℃ / min, the carbonization temperature is 900℃, and the carbonization time is 1h. Subsequently, continue to maintain N 2 Atmosphere, wait for the sample to cool to room temperature. Pour the cooled sample into a 1.8 mol / L sulfuric acid solution and mechanically shake for 30 minutes, then stand still, filter, and pickle the sample again with fresh sulfuric acid solution. Repeat the pickling several times until Mn is in the pickling solution 2+ The concentration cannot be detected. The acid-washed sample is washed with distilled water to neutrality, and finally the sample is dried in a blast drying oven at 105°C to obtain the mesoporous carbon of the present invention.

[0047] ...

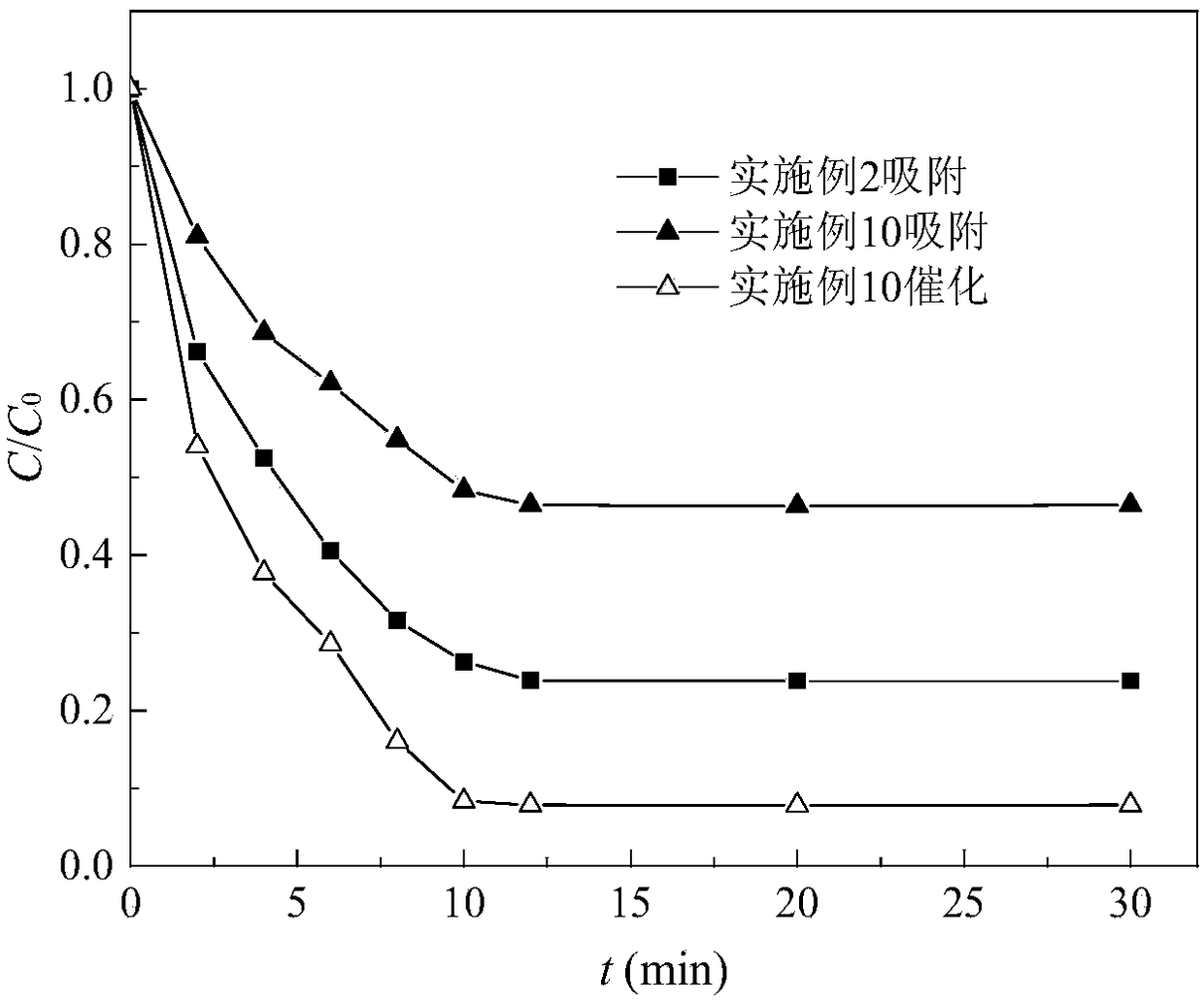

Embodiment 2

[0050] Grind the PVA solid particles to 200 mesh. The obtained PVA powder and manganese carbonate are uniformly mixed mechanically in a ratio of 1:3 (the mass ratio of PVA to MnO). Weigh a certain mass of mixed sample in a quartz tube furnace, 2 Carbonize the sample in the atmosphere. The heating rate is 5℃ / min, the carbonization temperature is 900℃, and the carbonization time is 1h. Subsequently, continue to maintain N 2 Atmosphere, wait for the sample to cool to room temperature. Pour the cooled sample into a 1.8 mol / L sulfuric acid solution and mechanically shake for 30 minutes, then stand still, filter, and pickle the sample again with fresh sulfuric acid solution. Repeat the pickling several times until Mn is in the pickling solution 2+ The concentration cannot be detected. The acid-washed sample is washed with distilled water to neutrality, and finally the sample is dried in a blast drying oven at 105°C to obtain the mesoporous carbon of the present invention.

[0051] ...

Embodiment 3

[0054] PVA solid particles were added to hot water at 80° C., and continuously stirred (rotation speed=600 r / min) to obtain a 20 wt.% PVA solution. Add manganese carbonate in a ratio of 1:3 (the mass ratio of PVA to MnO), continue to stir, and fully mix the manganese carbonate and the PVA solution. Pour the mixed solution into a quartz crucible and dry it overnight in a blast drying oven at 105°C. Place the dried sample in a quartz tube furnace at N 2 Carbonize the sample in the atmosphere. The heating rate is 5℃ / min, the carbonization temperature is 900℃, and the carbonization time is 1h. Subsequently, continue to maintain N 2 Atmosphere, wait for the sample to cool to room temperature. Pour the cooled sample into a 1.8 mol / L sulfuric acid solution and mechanically shake for 30 minutes, then stand still, filter, and pickle the sample again with fresh sulfuric acid solution. Repeat the pickling several times until Mn is in the pickling solution 2+ The concentration cannot be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com