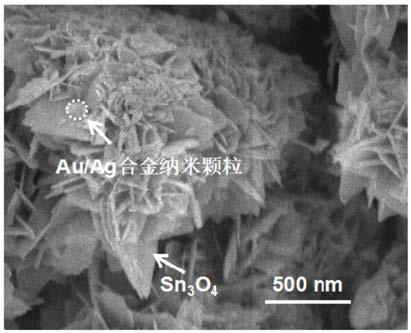

Preparation method of Au/Ag co-modified Sn3O4 nano composite photocatalytic material

A photocatalytic material and nanocomposite technology, applied in the field of preparation of nanocomposite photocatalytic materials, can solve the problems of obvious hard agglomeration effect of samples, demanding reaction conditions, easy falling off of supported metals, etc., and achieve excellent photocatalytic performance and morphology. Controllable, narrow particle size distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1) get 1mmol analytically pure stannous methanesulfonate (CH 3 SO 3 ) 2 Sn) and 0.5mmol of methanesulfonic acid (CH 4 o 3 S) fully dissolved in 3mL of absolute ethanol, and then sequentially added 0.5mmol of dodecyl ethoxy sulfobetaine and 13mL of deionized water to completely dissolve to obtain solution A;

[0029] 2) Take 1mmol analytically pure auric acid chloride (HAuCl 4 ), 1mmol of silver nitrate (AgNO 3 ) and 0.03mmol of methanesulfonic acid (CH 4 o 3 S) fully dissolved in 5mL of deionized water and mixed uniformly to obtain solution B;

[0030] Wherein steps 1 and 2) use a constant temperature magnetic stirring device to continuously magnetically stir it at 0° C. under an ice bath condition of crushed ice and water;

[0031] 3) Add solution B dropwise to solution A at a rate of 30 drops / min, then adjust its pH value to 4 with a NaOH solution with a concentration of 2mol / L, and use a constant temperature in an ice bath of crushed ice and water during the ...

Embodiment 2

[0035] 1) get 1mmol analytically pure stannous methanesulfonate (CH 3 SO 3 ) 2 Sn) and 2mmol of methanesulfonic acid (CH 4 o 3 S) fully dissolve in 12mL of absolute ethanol, then add 2.5mmol of dodecyl ethoxy sulfobetaine and 18mL of deionized water to dissolve completely to obtain solution A;

[0036] 2) Take 1mmol analytically pure auric acid chloride (HAuCl 4 ), 4mmol of silver nitrate (AgNO 3 ) and 3mmol of methanesulfonic acid (CH 4 o 3 S) Fully dissolved in 12mL of deionized water and mixed uniformly to obtain solution B;

[0037] Wherein steps 1 and 2) use a constant temperature magnetic stirring device to continuously magnetically stir it at 20° C. under an ice bath condition of crushed ice and water;

[0038] 3) Add solution B dropwise to solution A at a rate of 50 drops / min, then adjust its pH value to 7.5 with a NaOH solution with a concentration of 7mol / L, and use a constant temperature in the ice bath of crushed ice and water during the whole process A ma...

Embodiment 3

[0043] 1) get 1mmol analytically pure stannous methanesulfonate (CH 3 SO 3 ) 2 Sn) and 2.6mmol of methanesulfonic acid (CH 4 o 3 S) fully dissolved in 18mL of absolute ethanol, and then sequentially added 6mmol of dodecyl ethoxy sulfobetaine and 23mL of deionized water to completely dissolve to obtain solution A;

[0044] 2) Take 1mmol analytically pure auric acid chloride (HAuCl 4 ), 9mmol of silver nitrate (AgNO 3 ) and 5mmol of methanesulfonic acid (CH 4 o 3 S) Fully dissolved in 18mL of deionized water and mixed uniformly to obtain solution B;

[0045] Wherein steps 1 and 2) use a constant temperature magnetic stirring device to continuously magnetically stir it at 40° C. under an ice bath condition of crushed ice and water;

[0046] 3) Add solution B dropwise to solution A at a rate of 60 drops / min, then adjust its pH value to 9 with a NaOH solution with a concentration of 9mol / L, and use a constant temperature in an ice bath of crushed ice and water during the wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com