Method for directly loading photocatalyst and filling by layers and member thereof

A photocatalyst and loading technology, applied in the field of photocatalysis, can solve the problems of small porosity of the photocatalyst layer, poor light transmittance of the photocatalyst layer, and weak loading of the photocatalyst, so as to achieve enhanced photocatalytic effect, good adsorption performance, and avoidance of falling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

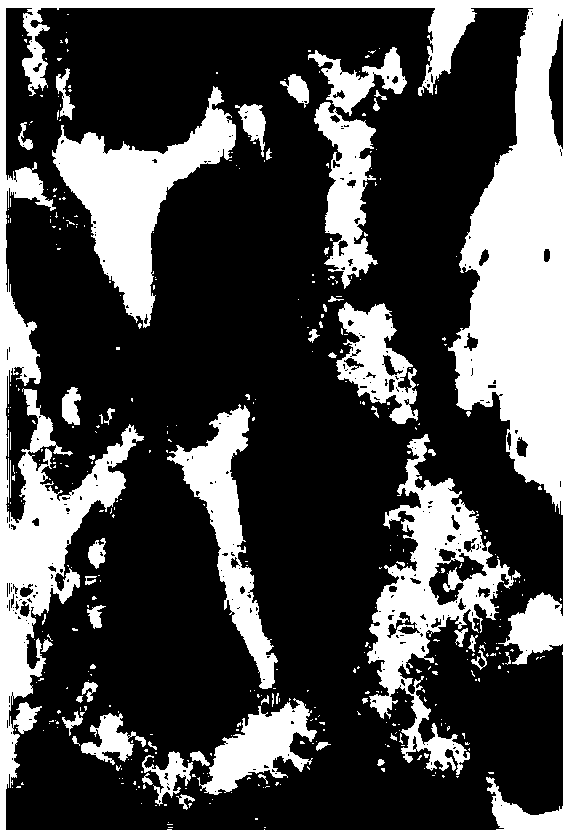

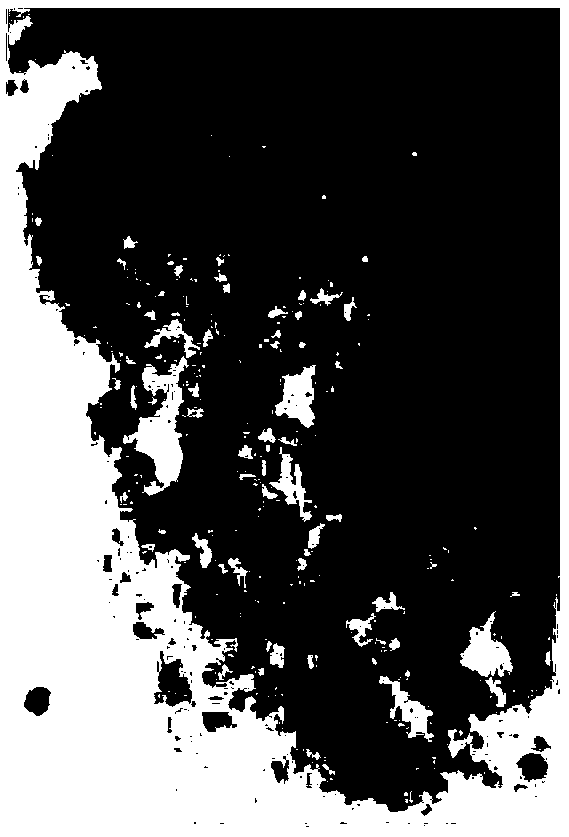

Embodiment 1

[0042] The steps of this embodiment include the preparation of the binder, the ultrasonic cleaning of the carrier, the combination of the carrier and the binder, the ultrasonic loading of the photocatalyst and the layered loading of the photocatalyst. The photocatalyst selected in this embodiment is Bi 2 WO 6 -TiO 2 Composite photocatalyst, using tetra-n-butyl titanate as titanium source, using sol-gel method and calcining at 550°C to prepare nano-powder TiO with photocatalytic activity 2 Photocatalyst, sodium tungstate and prepared nano-powder TiO with photocatalytic activity 2 As raw material, with acetone as solvent, TiO 2 The powder was added to the sodium tungstate solution and stirred, and the photocatalytically active nano-powder Bi 2 WO 6 -TiO 2 composite photocatalyst. The carrier selected in this embodiment is ceramic foam, Figure 1-3 The macroscopic topography, the 75-fold magnification and the 500-fold magnification of the foamed ceramics respectively. It c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com