Fluoride-free particle refining agent for aluminum alloy, and preparation method of refining agent

A manufacturing method and technology of aluminum alloy, applied in the field of material science, can solve the problems of limited slag removal effect, aluminum oxidation burning loss, large environmental pollution, etc., and achieve the effect of efficient slag removal, reduction of aluminum oxidation, and good effect of impurity removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

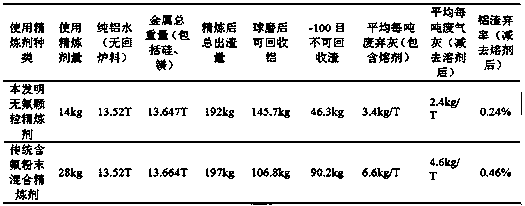

Embodiment 1

[0043] A kind of fluorine-free particle refining agent for aluminum alloy, made of MgCl 2 Powder 40Kg, KCl powder 40Kg, CaCl 2 Powder 10Kg, K 2 CO 3 Made of powder 10Kg.

[0044] A preparation method of a fluorine-free granular refining agent for aluminum alloys, comprising the following steps:

[0045] 1) Weigh MgCl 2 Powder 40Kg, KCl powder 40Kg, CaCl 2 Powder 10Kg, K 2 CO 3 Powder 10Kg, the weighed MgCl 2 powder, KCl powder, CaCl 2 Powder, K 2 CO 3 The powder is put into a double-crank mixer and mixed evenly to obtain a mixture.

[0046] 2) Put the mixture into a resistance crucible furnace equipped with an iron crucible.

[0047] 3) Turn on the resistance crucible furnace to heat up, and observe the melting situation while heating up.

[0048] 4) When the mixture starts to melt, reduce the heating power of the resistance crucible furnace and heat slowly, and ensure that the temperature rise rate of the mixture is less than or equal to 2°C / min.

[0049] 5) Aft...

Embodiment 2

[0056] A kind of fluorine-free particle refining agent for aluminum alloy, made of MgCl 2 Powder 50Kg, KCl powder 20Kg, CaCl 2 Powder 15Kg, K 2 CO 3 Made of powder 15Kg.

[0057] A preparation method of a fluorine-free granular refining agent for aluminum alloys, comprising the following steps:

[0058] 1) Weigh MgCl 2 Powder 50Kg, KCl powder 20Kg, CaCl 2 Powder 15Kg, K 2 CO 3 Powder 15Kg, the weighed MgCl 2 powder, KCl powder, CaCl 2 Powder, K 2 CO 3 The powder is put into a double-crank mixer and mixed evenly to obtain a mixture.

[0059] 2) Put the mixture into a resistance crucible furnace equipped with an iron crucible.

[0060] 3) Turn on the resistance crucible furnace to heat up, and observe the melting situation while heating up.

[0061] 4) When the mixture starts to melt, reduce the heating power of the resistance crucible furnace and heat slowly, and ensure that the temperature rise rate of the mixture is less than or equal to 2°C / min.

[0062] 5) Aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com