A high-pressure hydrogen storage alloy for hydrogen storage and its preparation method

A hydrogen storage alloy and high pressure technology, applied in the field of hydrogen storage materials, can solve the problems of inability to meet the hydrogen storage requirements of hydrogen refueling stations, unstable input and output, slow hydrogen charging and discharging rate, etc., achieve low enthalpy value, and reduce the number of openings , the effect of easily controllable conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The second aspect of the present invention provides a method for preparing a high-pressure hydrogen storage alloy for hydrogen storage, the method comprising the following steps:

[0037] Step 1, weighing each metal raw material, then mixing;

[0038] Step 2, melting the mixed metals to obtain a hydrogen storage alloy.

[0039] The preparation method of the hydrogen storage alloy described in the present invention is further described in detail below.

[0040] Step 1, weighing each metal raw material, and then mixing.

[0041] According to a preferred embodiment of the present invention, each elemental metal is weighed according to the ratio of the general formula, wherein, the purity of each elemental metal is: Ti≥99.7%, Cr≥99.5%, and the purity of Fe, Mn and A is equal to ≥99.9%.

[0042] In a further preferred embodiment, the added amount of Mn is greater than the added amount calculated according to the ratio in the general formula, preferably, the added amount o...

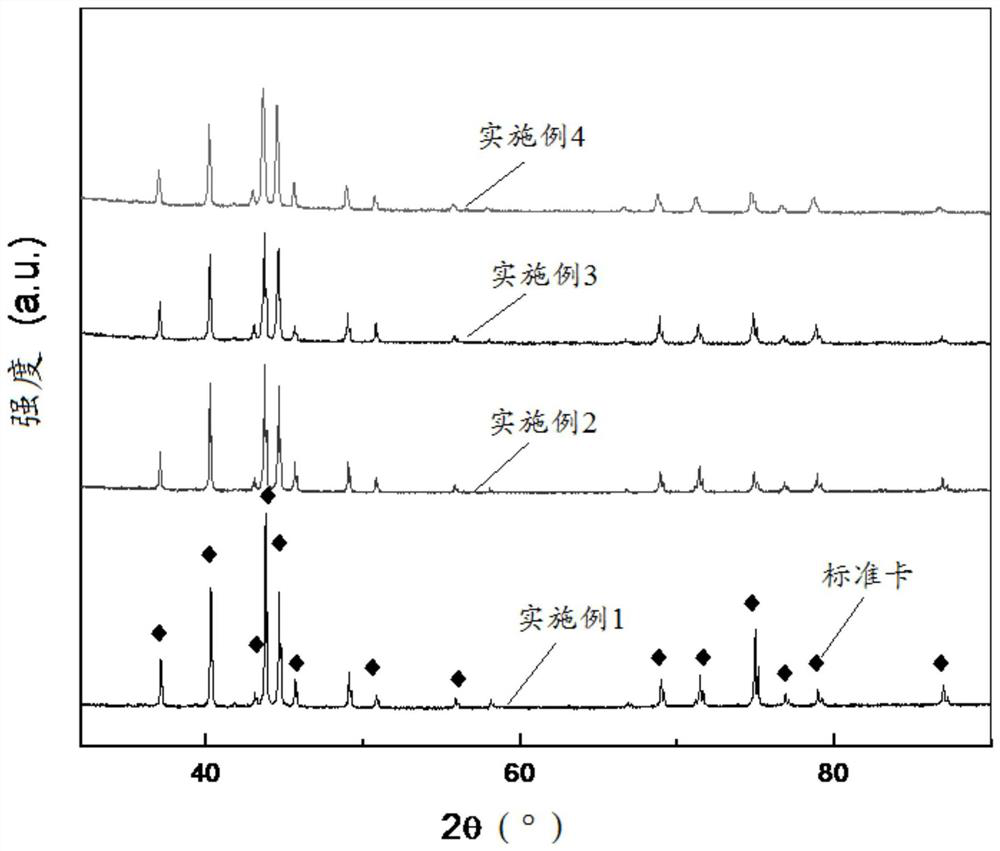

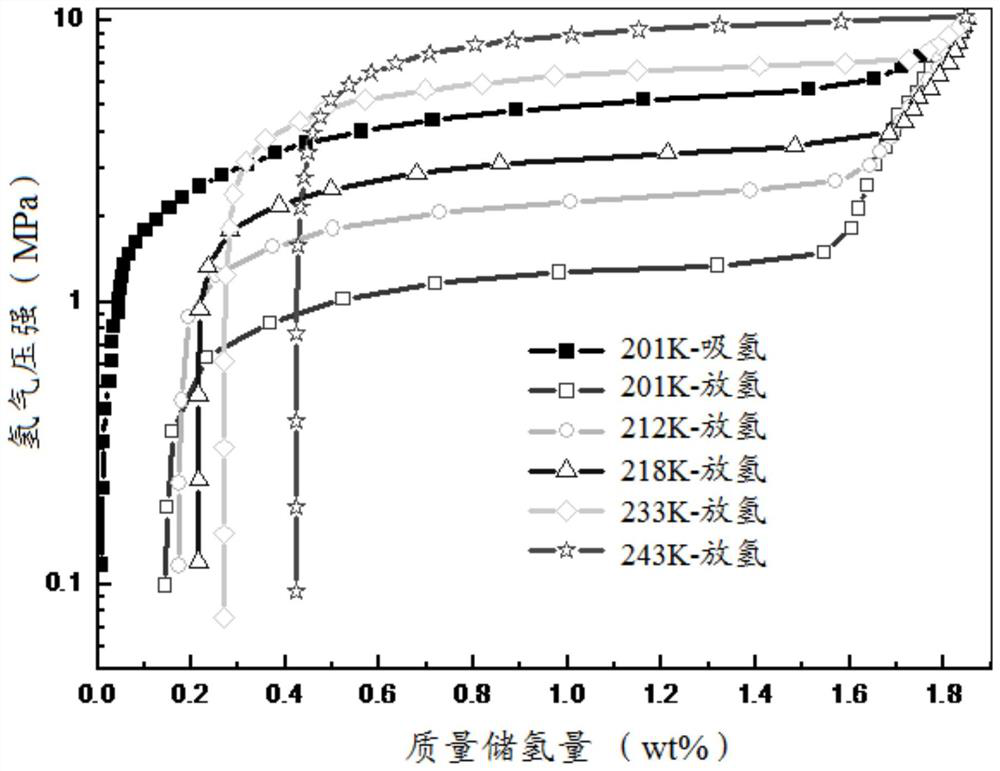

Embodiment 1

[0079] (1) The general formula is Ti 1.02 Cr 1.00 Fe 0.70 mn 0.30 The alloy is the target alloy expected to be prepared. Weigh Ti: 2.500g, Cr: 2.660g, Fe: 2.001g, Mn: 0.931g according to the proportion of the general formula, wherein Mn is excessive, mix them together and put them into an electric arc furnace (U.S. Miller Electric Manufacturing Company), vacuumize to 10 -3 Below Pa, introduce 0.9atm argon gas to start smelting, turn over 3 times in total, and smelt for 1.5min each time;

[0080] Among them, the purity of each metal element is: Ti>99.7%, Cr>99.5%, Fe>99.9%, Mn>99.9%, Al>99.9%; the purity of argon is 99.99%;

[0081] (2) Take out the alloy after smelting and weigh its mass, which is 8.025g, which differs from the mass 8g of the target alloy by 0.025g, and its difference exceeds the predetermined range of the target alloy;

[0082] (3) Put the smelted alloy into the electric arc furnace and vacuumize to 10 -3 Below Pa, introduce 0.9atm argon gas, repeat the...

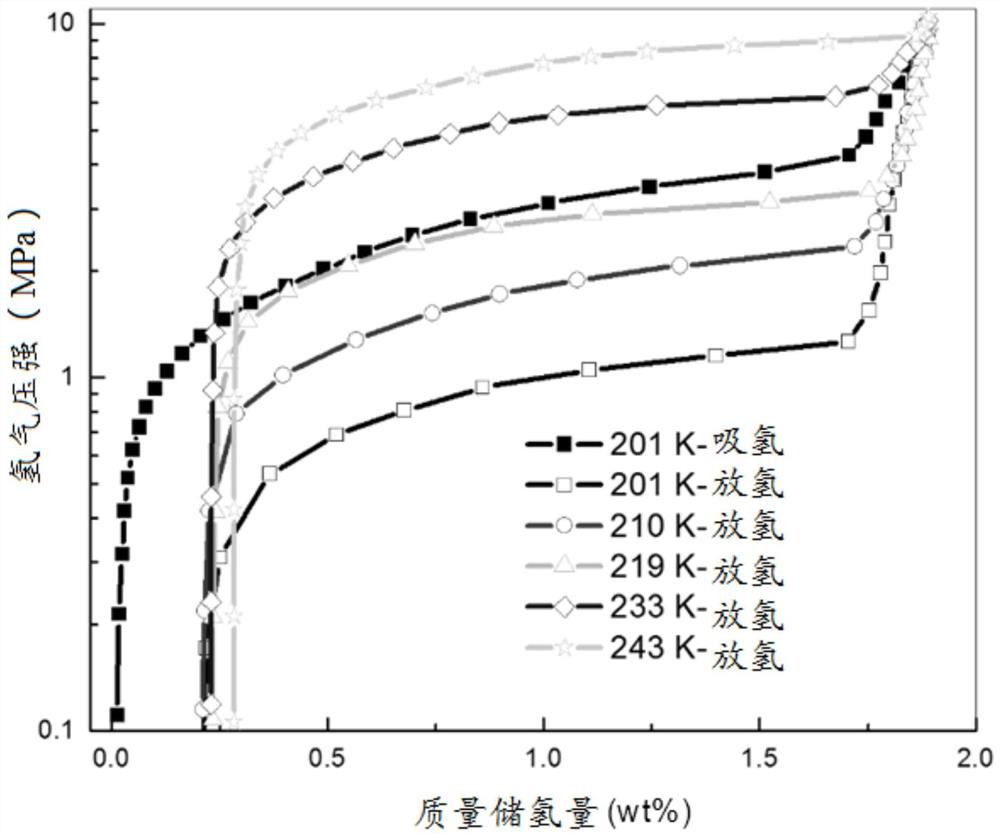

Embodiment 2

[0086] (1) The general formula is Ti 1.02 Cr 1.00 Fe 0.68 mn 0.30 Al 0.02 The alloy is the target alloy (8g) that is expected to be prepared. Weigh Ti: 2.507g, Cr: 2.670g, Fe: 1.950g, Mn: 0.951g, Al: 0.029g according to the proportion of the general formula, where Mn is excessive and mixed together Put it into an electric arc furnace (produced by Miller Electric Manufacturing Company in the United States), and evacuate to 10 -3 Below Pa, introduce 0.9atm argon gas to start smelting, turn over 3 times in total, and smelt for 1.5min each time;

[0087] Among them, the purity of each metal element is: Ti>99.7%, Cr>99.5%, Fe>99.9%, Mn>99.9%, Al>99.9%; the purity of argon is 99.99%;

[0088] (2) Take out the smelted alloy and weigh its mass, which is 7.990g, and the weight difference from the target alloy is within the range;

[0089](3) Put the above smelted alloy into a heat treatment furnace (Shanghai Chenxin Electric Furnace Co., Ltd., CXZW-20-20 or CXZG-0.5), and first v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com