Biodegradable composite film and preparation method thereof

A technology for mulching film and crop waste, applied in the biological field, can solve the problem of high production cost, achieve the effects of low cost, beneficial to agricultural mechanized production, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

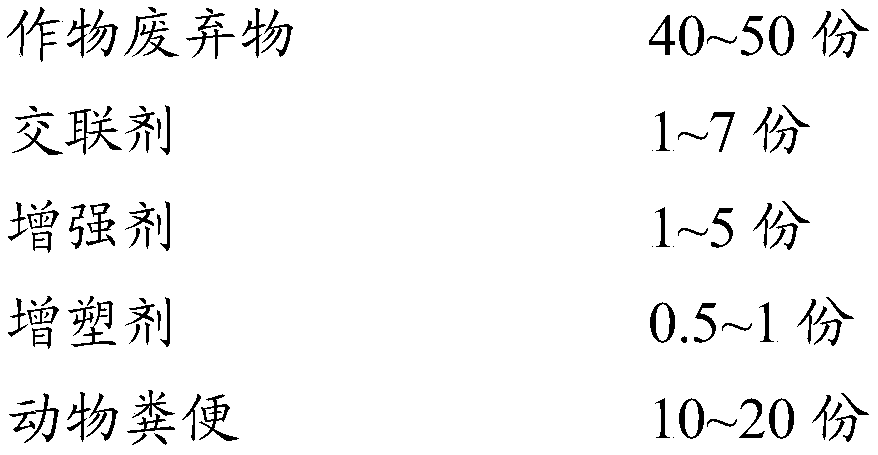

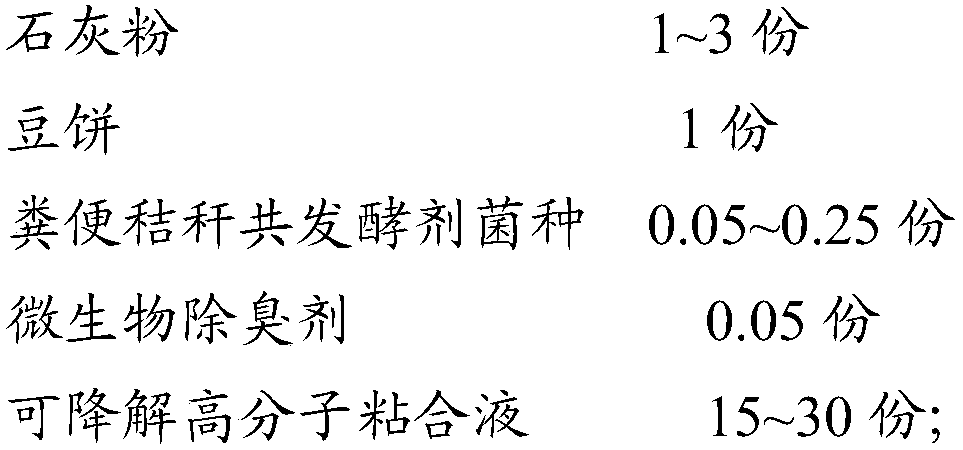

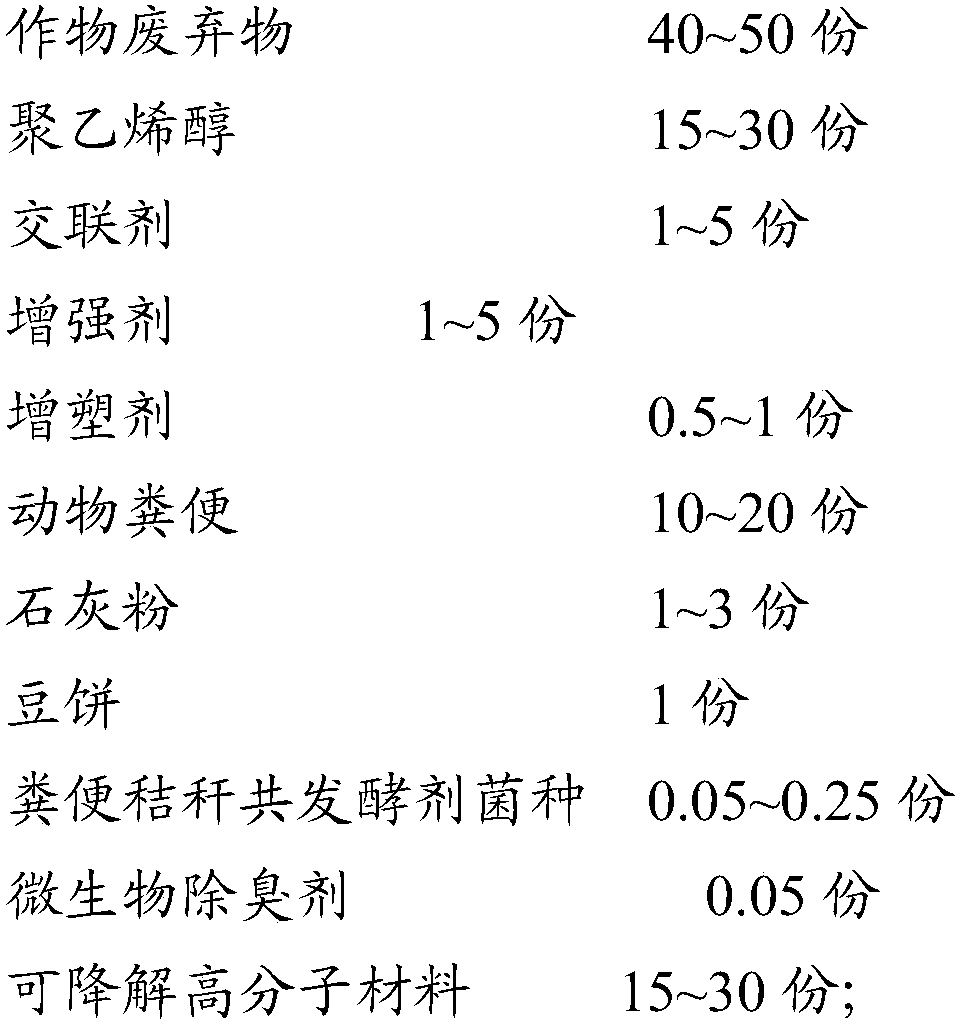

[0041] The present invention also provides a method for preparing the above-mentioned degradable composite mulch film, which includes the following steps:

[0042] 1) Mix crop waste, animal manure, lime powder, bean cake, and manure straw co-starter strains according to the mass parts to obtain a fermentation mixture; after mixing the fermentation mixture with water, perform fermentation and spray microbial deodorant in sequence And after drying, the fermentation product is obtained;

[0043] 2) After mixing the degradable polymer material, crosslinking agent, reinforcing agent, plasticizer and water, a degradable polymer mixture is obtained;

[0044] 3) The fermentation product obtained in step 1) is mixed with the degradable polymer mixture obtained in step 2) to form a film to obtain a degradable composite mulch film.

[0045] The invention mixes crop waste, animal manure, lime powder, bean cake, and manure straw co-starter strains according to the mass parts to obtain a fermentati...

Embodiment 1

[0059] 1) Mix 1000kg of bagasse, 200kg of cow dung, 30kg of lime powder, 20kg of bean cake and 5.0kg of manure straw co-starter strain, to obtain a fermentation mixture; mix the obtained fermentation mixture with 300Kg of water and ferment at 50-60°C for 3 days , Spray 6.5kg of microbial deodorant and dry naturally to obtain the fermentation product.

[0060] 2) After mixing 150 kg of polyvinyl alcohol with a mass concentration of 30%, 15 kg of hydrogen peroxide, 3 kg of calcium carbonate, 3 kg of dioctyl diacid, and 150 kg of a 10% sodium alginate aqueous solution, 100 g of 10 wt. % Calcium chloride aqueous solution to obtain a degradable polymer mixture.

[0061] 3) After mixing the obtained fermentation product with the degradable dry molecule mixture, casting into a film to obtain a wet film with a thickness of 4.5 mm, and natural drying to obtain a degradable composite mulch film.

Embodiment 2

[0063] 1) After mixing 1000kg of corn stalks, 200kg of chicken manure, 10kg of plant ash, 30kg of lime powder, 20kg of bean cake and 5kg of co-starter strain of manure straw, the fermentation mixture is obtained; after mixing the fermentation mixture with 300Kg of water, cover with plastic cloth Fermentation, the temperature of fermentation is 60~70℃, after 5 days of fermentation, 5.0kg of microbial deodorant is sprayed, and after natural drying, the fermentation product is obtained;

[0064] 2) After mixing 30% polyvinyl alcohol 500 kg, acetaldehyde 20 kg, dioctyl phthalate 5 kg, 0.5 kg crosslinking agent and 100 kg 10% by mass of sodium carboxymethyl cellulose aqueous solution, the degradable Polymer mixture

[0065] 3) After mixing the obtained fermentation product with the degradable polymer mixture, casting into a film to obtain a wet film with a thickness of 25 mm, and natural drying to obtain a degradable composite mulch film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com