Cold-resistant and crack-resistant PVC resin for door and window plastic steel profiles

A technology of PVC resin and plastic steel for doors and windows, applied in the field of polymer materials, can solve the problems of material toughness and low temperature resistance, poor high temperature resistance, brittle deformation of PVC resin, and the influence of material mechanical strength, etc. Low temperature performance, effect of improving processing characteristics and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

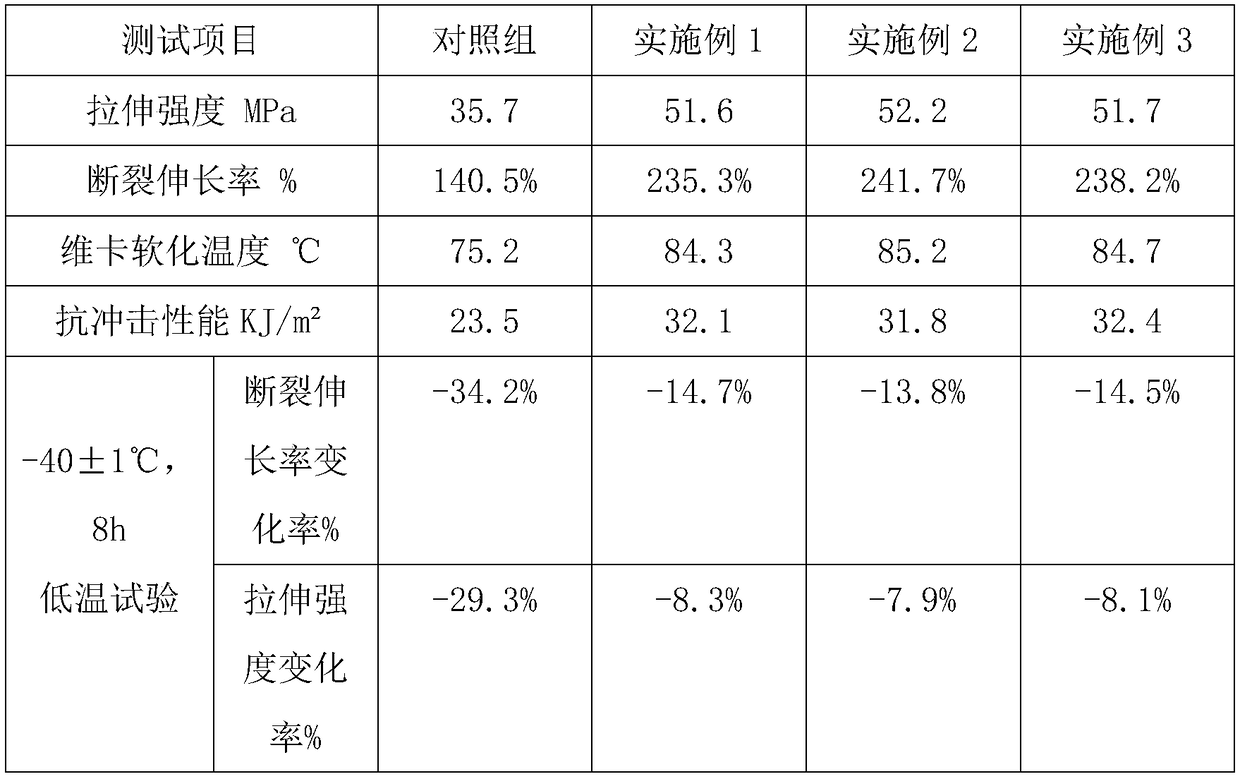

Examples

Embodiment 1

[0036] A PVC resin for cold-resistant and crack-resistant door and window plastic-steel profiles. According to the mass parts, the components of the PVC resin include: 100 parts of PVC, 4 parts of ACR processing aid, 18 parts of filler, 6 parts of cold-resistant toughening agent, polyethylene wax 0.5 part, 1 part of composite stabilizer, 0.4 part of ultraviolet absorber, 0.2 part of antioxidant.

[0037] Wherein, the filler is a mixture of titanium dioxide and light calcium carbonate mixed at a ratio of 6:1.

[0038] The composite stabilizer contains calcium zinc stabilizer and di-n-butyltin dilaurate.

[0039] The ultraviolet absorber is ultraviolet absorber RMB; the antioxidant is antioxidant 164.

[0040] The preparation method of the PVC resin that present embodiment provides is:

[0041] According to the parts by mass, PVC, ACR processing aids, fillers, cold-resistant toughening agents, polyethylene wax, composite stabilizers, ultraviolet absorbers, and antioxidants are...

Embodiment 2

[0043] A PVC resin for cold-resistant and crack-resistant door and window plastic-steel profiles. According to the parts by mass, the components of the PVC resin include: 120 parts of PVC, 7 parts of ACR processing aid, 25 parts of filler, 9 parts of cold-resistant toughening agent, polyethylene wax 1.2 parts, 3 parts of composite stabilizer, 0.8 part of ultraviolet absorber, 0.5 part of antioxidant.

[0044] Wherein, the filler is a mixture of titanium dioxide and light calcium carbonate mixed at a ratio of 6:1.

[0045] The composite stabilizer contains calcium zinc stabilizer and di-n-butyltin dilaurate.

[0046] The ultraviolet absorber is ultraviolet absorber UV-9; the antioxidant is antioxidant 1076.

[0047] The preparation method of the PVC resin that present embodiment provides is:

[0048] According to the parts by mass, PVC, ACR processing aids, fillers, cold-resistant toughening agents, polyethylene wax, composite stabilizers, ultraviolet absorbers, and antioxida...

Embodiment 3

[0050] A PVC resin for cold-resistant and crack-resistant door and window plastic-steel profiles. According to the mass parts, the components of the PVC resin include: 110 parts of PVC, 5.5 parts of ACR processing aid, 21 parts of filler, 7 parts of cold-resistant toughening agent, polyethylene wax 0.9 parts, 2.2 parts of composite stabilizers, 0.6 parts of ultraviolet absorbers, and 0.4 parts of antioxidants.

[0051] Wherein, the filler is a mixture of titanium dioxide and light calcium carbonate mixed at a ratio of 6:1.

[0052] The composite stabilizer contains calcium zinc stabilizer and di-n-butyltin dilaurate.

[0053] The ultraviolet absorber is ultraviolet absorber UVP-327; the antioxidant is antioxidant TNP.

[0054] The preparation method of the PVC resin that present embodiment provides is:

[0055] According to the parts by mass, PVC, ACR processing aids, fillers, cold-resistant toughening agents, polyethylene wax, composite stabilizers, ultraviolet absorbers, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com