Waterproof cable and preparation method thereof

A technology for waterproof cables and particulate matter, which is used in the manufacture of cables/conductors, insulated cables, cables, etc., and can solve the problems of wet environment and easy damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

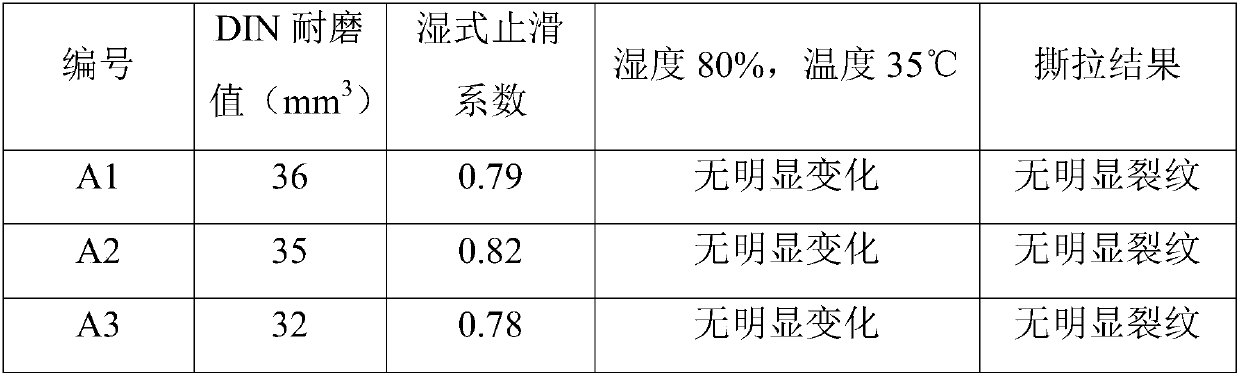

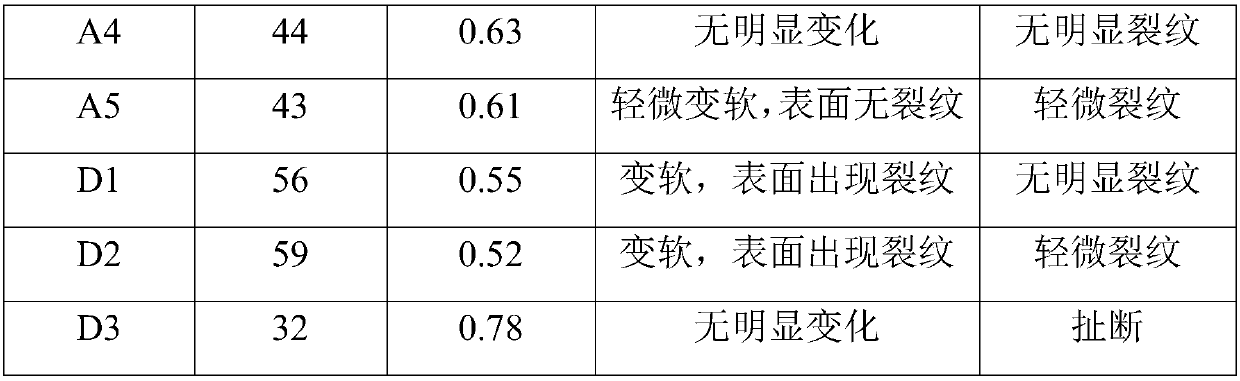

Examples

preparation example Construction

[0016] The invention provides a preparation method of a waterproof cable, wherein the preparation method comprises:

[0017] 1) Soak mica powder and talc powder in dodecyl dimethyl tertiary amine and take them out to obtain particulate matter M1;

[0018] 2) roasting after mixing the above-mentioned particles M1, white carbon black and graphite, to obtain mixed particles M2;

[0019] 3) mixing and melting natural rubber, EPDM rubber, the above-mentioned mixed particles M2, paraffin, monoglyceride stearate, naphthenic oil and processing aids, and extruding to form a rubber sleeve;

[0020] 4) Stranding a plurality of silver-plated copper-clad steels to obtain a wire core;

[0021] 5) Wrap the wire core with the rubber sheath to make a waterproof cable.

[0022] In the present invention, mica powder and talc powder are soaked in dodecyl dimethyl tertiary amine, so that the specific surface area of mica powder and talc powder etc. are modified to a certain extent, and then th...

Embodiment 1

[0034] 1) Place 10 parts by weight of mica powder and 2 parts by weight of talc powder in dodecyldimethyl tertiary amine at a temperature of 40°C, stir and soak at a stirring rate of 100r / min, take out, and wash with ethanol and Drying after washing with water to obtain particulate matter M1;

[0035] 2) Mix 10 parts by weight of the above particles M1, 3 parts by weight of white carbon black and 1 part by weight of graphite, and then roast at a temperature of 400° C. to prepare mixed particles M2;

[0036] 3) 100 parts by weight of natural rubber, 20 parts by weight of EPDM rubber, 20 parts by weight of the above-mentioned mixed particles M2, 5 parts by weight of paraffin, 1 part by weight of monoglyceride stearate, 20 parts by weight of naphthenic oil , 2 parts by weight of vulcanizing agent and 2 parts by weight of accelerator are mixed and smelted at 130°C, and then extruded through a die with a temperature of 160°C to obtain a rubber sleeve;

[0037] 4) Stranding three s...

Embodiment 2

[0040] 1) 10 parts by weight of mica powder and 6 parts by weight of talc powder were placed in dodecyldimethyl tertiary amine at a temperature of 50 ° C and soaked at a stirring rate of 300 r / min, then taken out, and washed with ethanol and Drying after washing with water to obtain particulate matter M1;

[0041] 2) Mix 10 parts by weight of the above particles M1, 5 parts by weight of white carbon black and 2 parts by weight of graphite, and then roast at a temperature of 600° C. to prepare mixed particles M2;

[0042] 3) 100 parts by weight of natural rubber, 40 parts by weight of EPDM rubber, 30 parts by weight of the above-mentioned mixed particles M2, 10 parts by weight of paraffin, 2 parts by weight of monoglyceride stearate, 30 parts by weight of naphthenic oil , 2 parts by weight of vulcanizing agent and 2 parts by weight of accelerator are mixed and smelted at 160°C, and then extruded through a die with a temperature of 170°C to obtain a rubber sleeve;

[0043] 4) S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com