Waterproof and dustproof self-radiating type motor-driven automobile direct current voltage changer

An electric vehicle, DC voltage technology, applied in the direction of converting DC power input to DC power output, adjusting electrical variables, instruments, etc., to achieve the effect of improving heat dissipation performance, solving heat dissipation problems, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

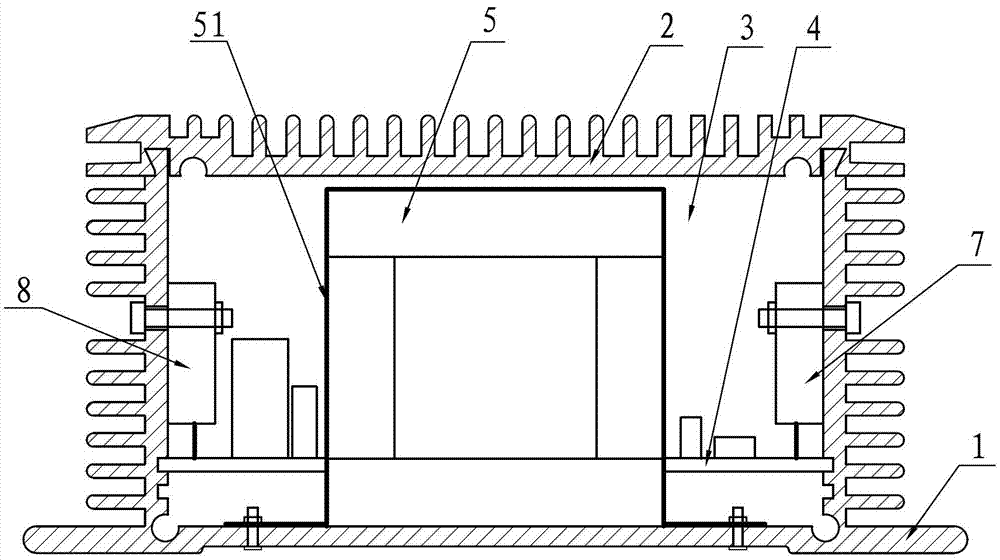

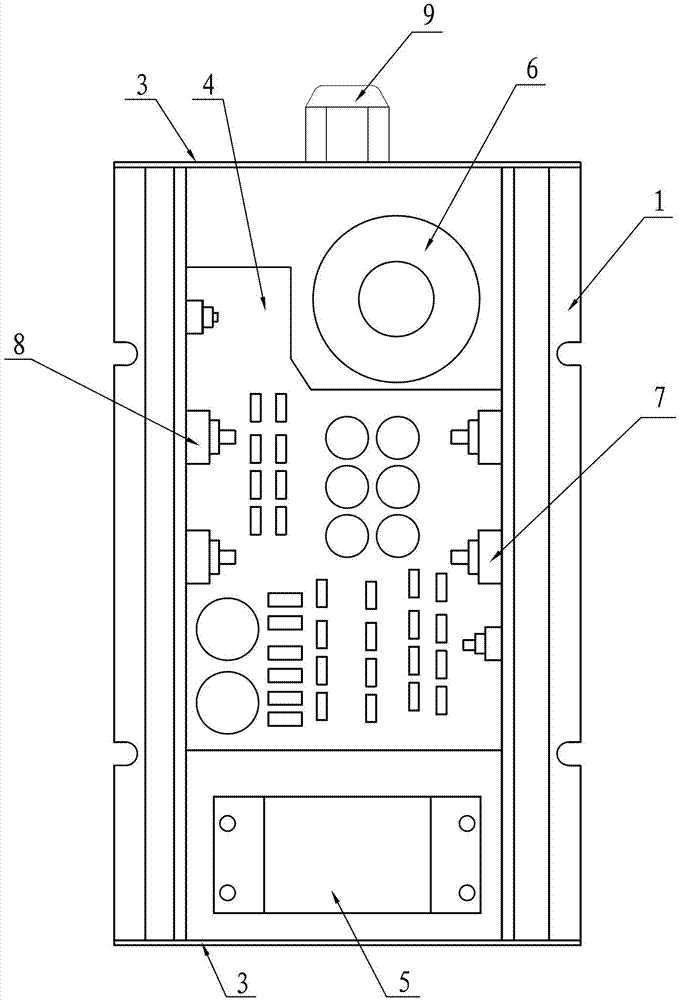

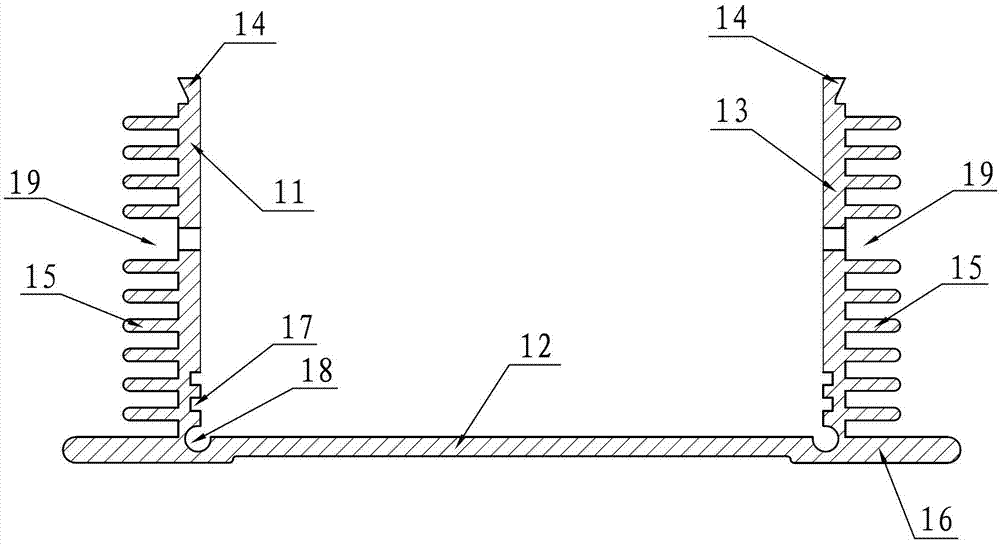

[0018] Embodiment 1: A waterproof and dustproof self-heating electric vehicle DC voltage converter, including a heat dissipation housing 1, a heat dissipation cover plate 2, a side sealing plate 3, a circuit board 4, a transformer 5, a coil 6, a Schottky diode 7 and Field effect tube 8, the heat dissipation housing 1 includes a left side plate 11, a bottom plate 12, a right side plate 13, a matching convex body 14, a heat sink 15, an installation bottom surface 16, a circuit board slot 17 and an installation hole 18, on the left The outer surfaces of the side plate 11 and the right side plate 13 are provided with cooling fins 15, and the tops of the left side plate 11 and the right side plate 13 are provided with matching convex bodies 14. Circuit board slots 17 are provided at equal heights on the inner side, and the distance between the circuit board slots 17 and the inner surface of the bottom plate 12 is greater than or equal to 3 millimeters, and the outer surfaces of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com