Waterproof and explosion-proof fire extinguishing box of cable connector

A technology of cable joints and fire extinguishing boxes, applied in the direction of cable joints, etc., can solve the problems of insulation performance degradation, increase failure rate, insulation breakdown of protective layer, etc., achieve convenient use and storage, improve production efficiency, and good sealing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further illustrated below in conjunction with the accompanying drawings and specific examples. The examples are implemented on the premise of the technical solutions of the present invention. It should be understood that these examples are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

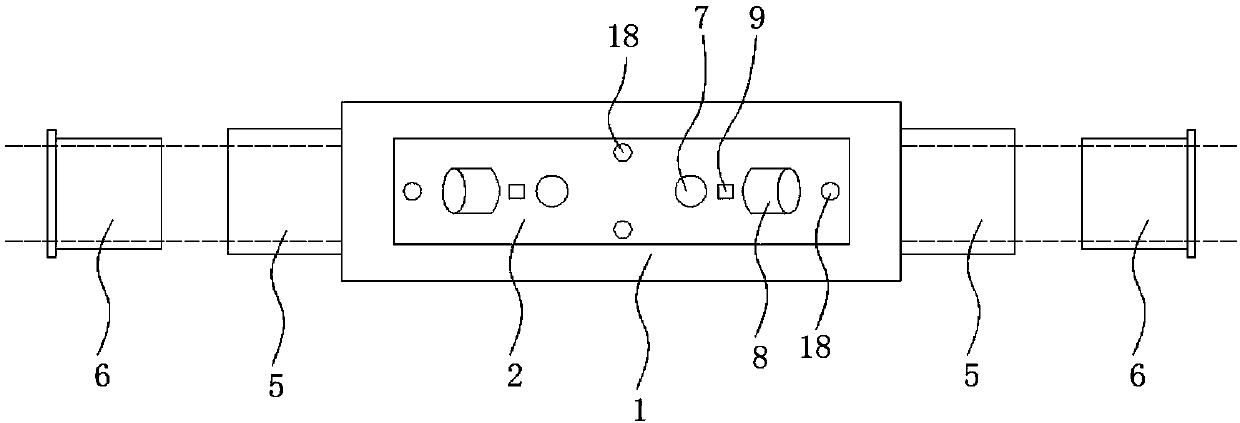

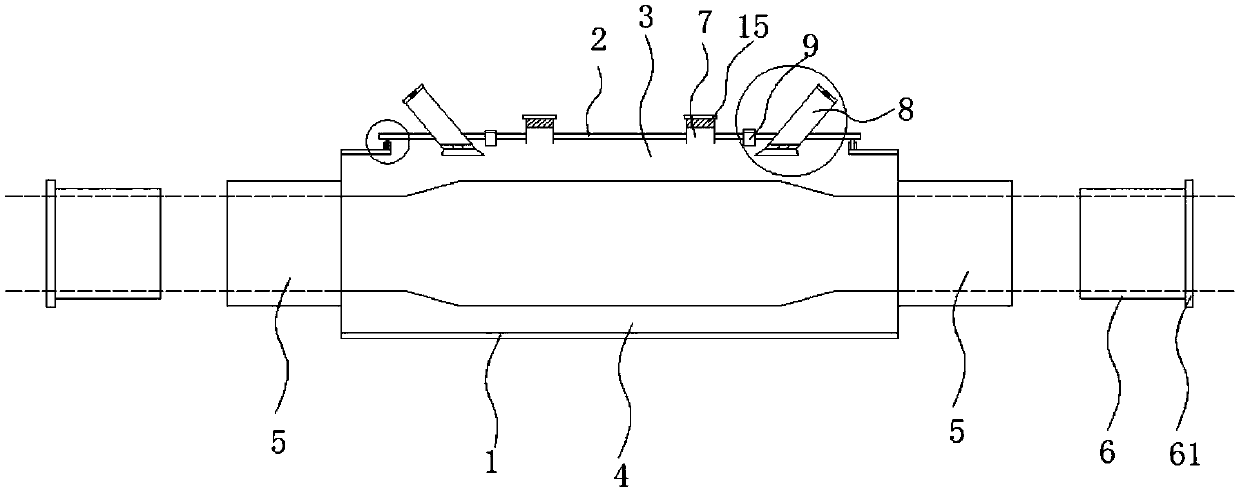

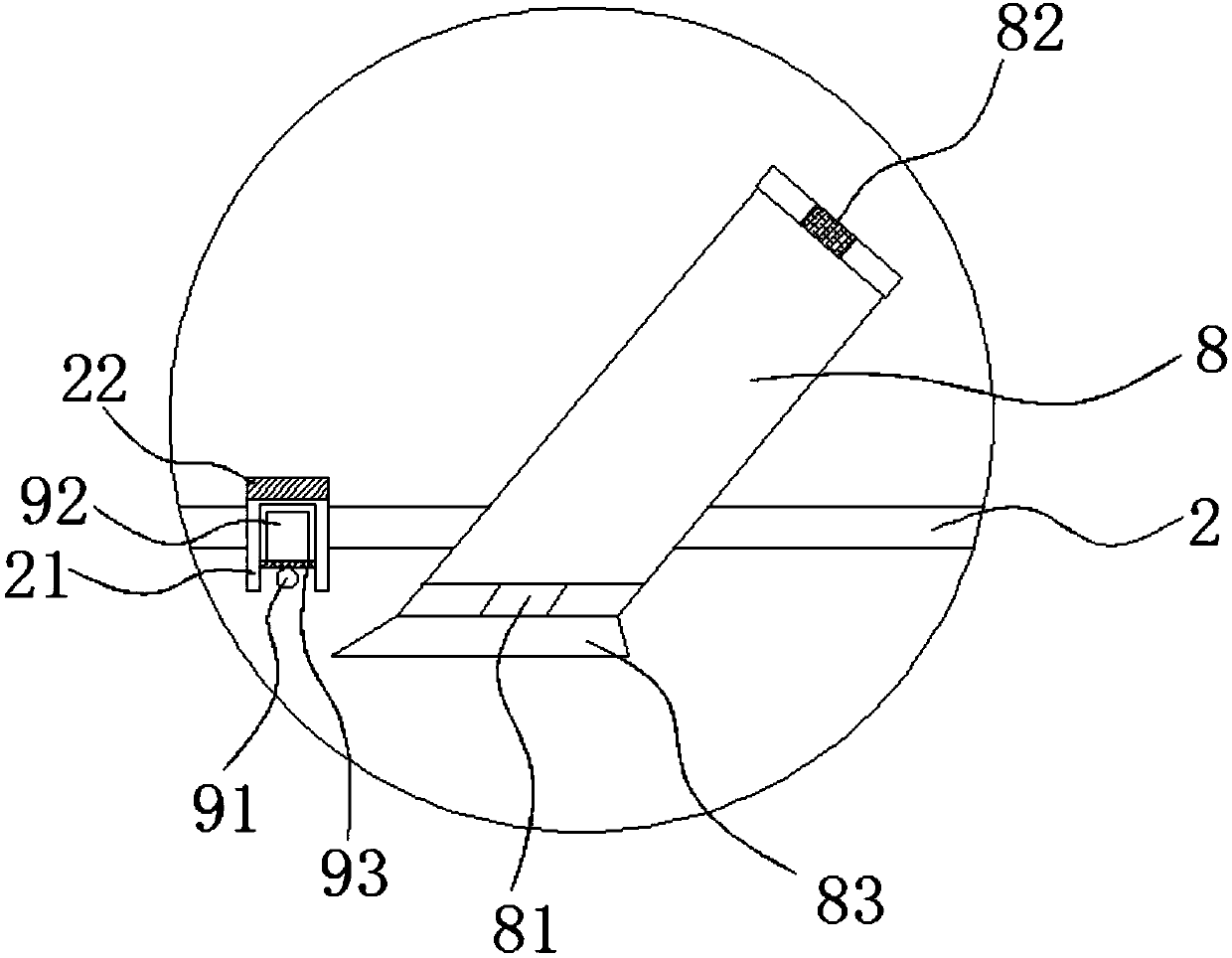

[0023] Such as Figures 1 to 4 As shown, a cable joint waterproof and explosion-proof fire extinguishing box includes a cavity 1 and a cover 2, an opening 3 is opened on the upper end surface of the cavity 1, and a detachable cover 2 is arranged on the opening 3, and the cover 2 and the cavity The body 1 is connected to form a closed cable joint explosion-proof chamber 4; two sets of energy dissipation conduits 7 are arranged on the cover body 2, and two sets of fire extinguishing assemblies are arranged on the cover body 2. The fire extinguishing assemblies include a fire extinguishing pipe 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com