A medical composite gel with multiple biological functions, preparation method and application thereof

A composite gel and functional technology, which is applied in the field of medical composite gel preparation, can solve the problems of affecting biological effects, low initial mechanical strength, and destroying porous structures, and achieves low preparation costs, low equipment requirements, and inhibition of cancer cells Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Add 10% of polyvinyl alcohol into deionized water by mass percentage, heat and stir until it is completely dissolved to obtain a gel aqueous solution; after standing at 20°C for 1 hour, a viscous liquid is obtained; pure magnesium particles with an average particle size of 150 μm are % was added to the viscous liquid, stirred and mixed thoroughly, and left to stand at 4°C for 24 hours to obtain a multi-biological functional medical composite gel. Soaked in deionized water, it can absorb 2 times its own weight in water at balance. After absorbing water and balance, its compressive strength is 10±4kPa, and its elongation at break is 200±25%. Other conditions were the same, and the polyvinyl alcohol gel prepared without adding pure magnesium particles was used as the control group.

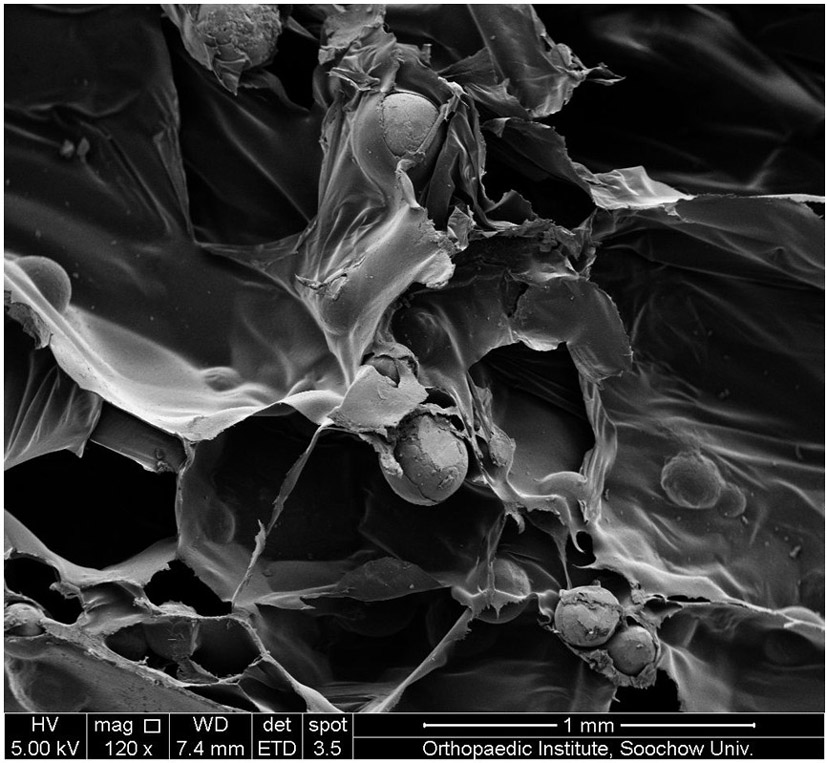

[0028] After freeze-drying, the microscopic morphology of the composite gel was observed by scanning electron microscopy. See attached figure 1 , which is a scanning electron micrograph of a...

Embodiment 2

[0034] Add sodium alginate 2.5% by mass into deionized water, heat and stir until it is completely dissolved, then cool the aqueous gel solution to 25°C to obtain a viscous liquid; Add 8% by mass to the viscous liquid, stir and mix thoroughly, add 0.1M calcium chloride solution, the gel is fully cross-linked, and after drying, a multi-biological functional medical composite gel is obtained. Soaked in deionized water, it can absorb 10 times its own weight in water at balance. After absorbing water and balance, its compressive strength is 1±0.3kPa, and its elongation at break is 110±15%. Other conditions were the same, and the alginic acid gel prepared without adding magnesium-zinc alloy particles was used as the control group.

[0035] Use the conditions of Example 1 to soak in vitro, and measure the concentration of magnesium ions and zinc ions in the soaking solution before changing the solution for 28 days. The results showed that the magnesium ion concentration in the comp...

Embodiment 3

[0039] Add 20% gelatin to deionized water by mass percentage, heat and stir until it is completely dissolved to obtain a gel aqueous solution; cool the obtained gel aqueous solution to 37°C; 100 mesh zinc-copper (Zn-2Cu) alloy powder 10% was added to the liquid, and under the condition of sufficient stirring, 20% by mass of 1 wt% glutaraldehyde solution was added to obtain a composite gel after rapid cross-linking, and the composite gel was placed at 4°C for 24 hours to fully cross-link. After fully rinsing and drying with deionized water, a multi-biological functional medical composite gel is obtained. Soaked in deionized water, the composite gel can absorb 4.5 times its own weight in water at equilibrium. After water absorption equilibrium, its compressive strength is 100±40kPa, and its elongation at break is 50±7%. Other conditions were the same, and the gelatin gel prepared without adding zinc-copper alloy particles was used as the control group.

[0040] The in vitro imm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com