Heating method for casting blank corner part

A heating method and corner technology, which is applied in the field of metallurgy, can solve the problems of edge quality degradation, large amount of trimming, and easy cracks on the edge, so as to reduce the degree of generation and cracking, increase the temperature of the slab, and avoid edge cracking. cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

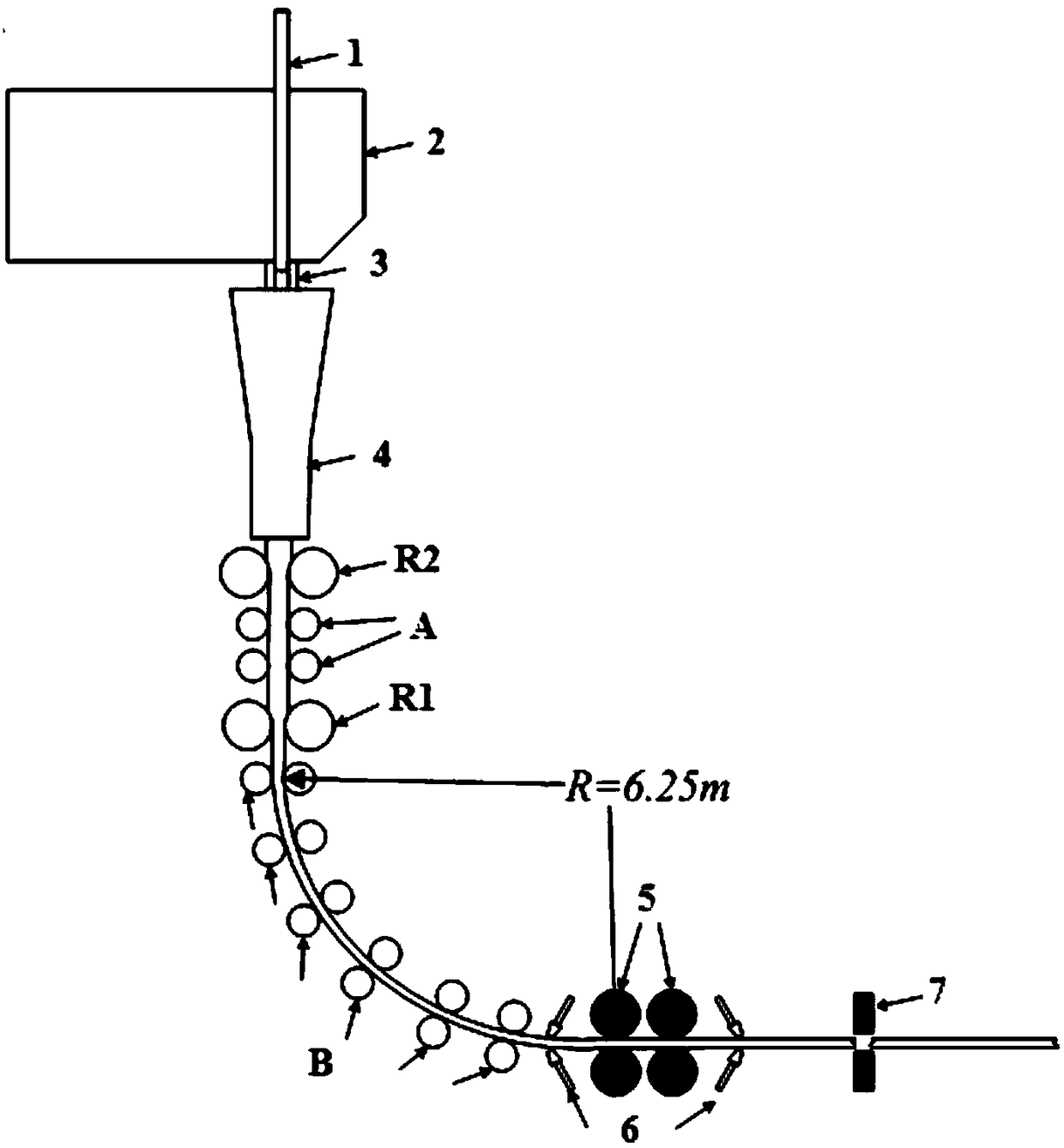

[0030] A method for heating the corners of a slab, the schematic diagram of the arrangement of the coal-oxygen lances used in the continuous casting equipment is as follows figure 1 As shown, the continuous casting equipment includes stopper rod 1, tundish 2, submerged nozzle 3, crystallizer 4, first group of reduction device R1, second group of reduction device R2, secondary cooling 1-2 stage A, secondary cooling Section 3-8 B, stretching and straightening device 5, coal oxygen gun 6, cutting device 7, specifically includes the following steps:

[0031] (1) The billet material is Q195 steel;

[0032] (2) The flow range of gas and oxygen is controlled, and the total flow before pulling and straightening rollers is 500m of coke oven gas 3 / h-Oxygen 400m 3 / h, the total flow before the bending roller is 700m of coke oven gas 3 / h-Oxygen 560m 3 / h;

[0033] (3) The distance from the nozzle of the coal oxygen gun 6 to the corner is 100mm;

[0034] (4) Thickness of billet is ...

Embodiment 2

[0038] A method for heating the corners of a slab, wherein the arrangement of the coal-oxygen lances used in the continuous casting equipment is the same as that in Embodiment 1, specifically comprising the following steps:

[0039] (1) The billet material is Q235A steel;

[0040] (2) The control gas and oxygen flow range is as follows, and the total flow rate before pulling and straightening rollers is 400m for coke oven gas 3 / h-Oxygen 320m 3 / h, the total flow before the bending roller is 500m of coke oven gas 3 / h-Oxygen 400m 3 / h;

[0041] (3) The distance from the nozzle of the coal oxygen lance to the corner is 120mm;

[0042] (4) Thickness of billet: 50mm;

[0043] (5) The amount of supplementary heat at the corner is adjusted by the gas flow and flame distance. It is operated manually. The eight coal oxygen guns have linkage and single-action designs. Adjust the color according to the color conditions. When the flame is turned off, you should first close the gas...

Embodiment 3

[0046] A method for heating the corners of a slab, wherein the arrangement of the coal-oxygen lances used in the continuous casting equipment is the same as that in Embodiment 1, specifically comprising the following steps:

[0047] (1) The billet material is Q195 steel;

[0048] (2) The control gas and oxygen flow range is as follows, and the total flow rate before pulling and straightening rollers is 800m for coke oven gas 3 / h-Oxygen 800m 3 / h, the total flow before the bending roller is 800m for coke oven gas 3 / h-Oxygen 800m 3 / h;

[0049] (3) The distance from the nozzle of the coal oxygen lance to the corner is 100mm;

[0050] (4) Thickness of billet: 120mm;

[0051](5) The amount of supplementary heat at the corner is adjusted by the gas flow and the distance of the flame. It is operated manually. The eight coal oxygen guns have linkage and single-action designs. Adjust the color according to the color conditions. When the flame is turned off, you should first cl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com