Ultra-low carbon easy-to-weld medium manganese automotive steel with controllable yield ratio and preparation method thereof

An ultra-low-carbon, easy-to-weld technology, applied in the field of automotive steel, can solve problems such as increasing the difficulty of welding, and achieve the effects of avoiding the formation of hard and brittle phases, improving strong plasticity, and facilitating industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

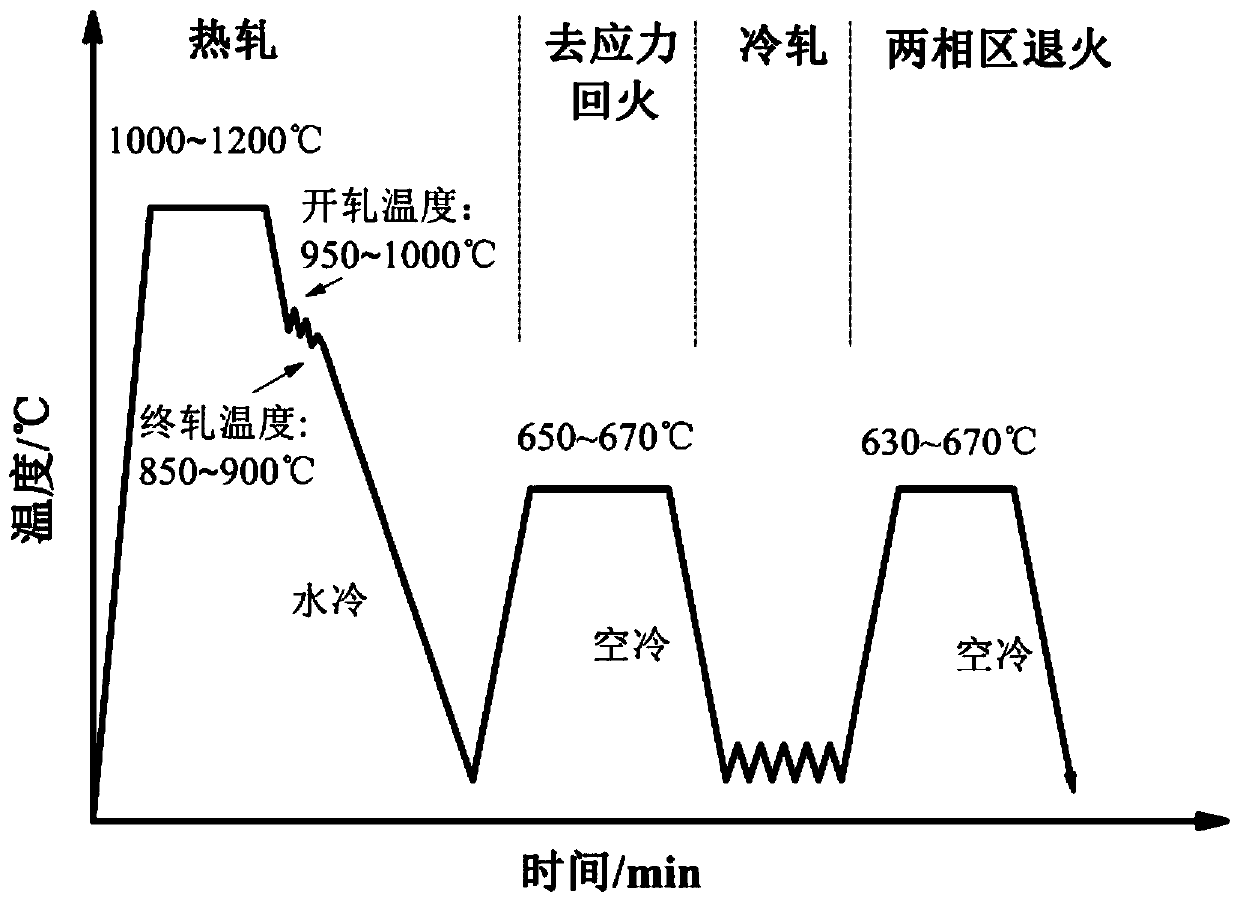

[0036] Preparation thickness is 0.5mm ultra-low carbon easy-to-weld medium manganese automobile steel plate, such as figure 1 As shown, the process steps are as follows:

[0037] (1) hot rolling treatment

[0038] The alloy billet is heated to 1000°C with the furnace and kept for 3 hours. The chemical composition of the alloy billet by weight percentage is: C: 0.02%, Mn: 8.5%, Si: 0.10%, S: 0.003%, P: 0.002%, Al: 0.05%, Cu: 0.30%, Ni: 0.20%, Mo: 0.16%, Cr: 0.02%, the balance is Fe and other unavoidable impurities; followed by 6 passes of hot rolling into a 2.7mm thick hot rolled sheet, The starting rolling temperature and finishing rolling temperature are 950°C and 850°C respectively, and after the hot rolling is finished, the cooling rate is 10°C / s and cooled to room temperature to obtain lath martensitic structure with high dislocation density;

[0039] (2) Stress relief tempering treatment

[0040] After the heating furnace is heated to 650°C, put the hot-rolled and quen...

Embodiment 2

[0046] Preparation thickness is 1.0mm ultra-low carbon easy-to-weld medium manganese automobile steel plate, such as figure 1 As shown, the process steps are as follows:

[0047] (1) hot rolling treatment

[0048] The alloy billet is heated to 1200°C with the furnace and kept for 3 hours. The chemical composition of the alloy billet by weight percentage is: C: 0.04%, Mn: 5.5%, Si: 0.25%, S: 0.003%, P: 0.002%, Al: 0.03%, Cu: 0.25%, Ni: 0.30%, Mo: 0.20%, Cr: 0.30%, the balance is Fe and other unavoidable impurities; followed by 6 passes of hot rolling into a 3.2mm thick hot rolled sheet, The starting and finishing temperatures are 1000°C and 900°C, respectively. After hot rolling, the cooling rate is 25°C / s to room temperature, and finally a lath martensitic structure with high dislocation density is obtained;

[0049] (2) Stress relief tempering treatment

[0050] After the heating furnace is heated to 670°C, the hot-rolled and quenched steel plate is put into the furnace fo...

Embodiment 3

[0056] Preparation thickness is 1.5mm ultra-low carbon easy-to-weld medium manganese automobile steel plate, such as figure 1 As shown, the process steps are as follows:

[0057] (1) hot rolling treatment

[0058] The alloy billet is heated to 1150°C with the furnace and kept for 3 hours. The chemical composition of the alloy billet by weight percentage is: C: 0.06%, Mn: 3.5%, Si: 0.50%, S: 0.003%, P: 0.002%, Al: 0.01%, Cu: 0.02%, Ni: 0.02%, Mo: 0.02%, Cr: 0.40%, the balance is Fe and other unavoidable impurities; followed by 6 passes of hot rolling into a 4.0mm thick hot rolled sheet, The starting rolling temperature and the final rolling temperature are 960°C and 880°C respectively, and after the hot rolling is finished, the cooling rate is 20°C / s to room temperature, and finally a lath martensitic structure with high dislocation density is obtained;

[0059] (2) Stress relief tempering treatment

[0060] After the heating furnace is heated up to 660°C, put the hot-rolled...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com