Sawing apparatus and process for producing a scintillator structured into scintillator elements and scintillator having scintillator elements

A technology of scintillator and sawing device, which is applied in the direction of manufacturing tools, fine working devices, radiation intensity measurement, etc., can solve the problems of high cost and time-consuming, and achieve the goals of improving heat discharge, good sawing tolerance, and reducing processing time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

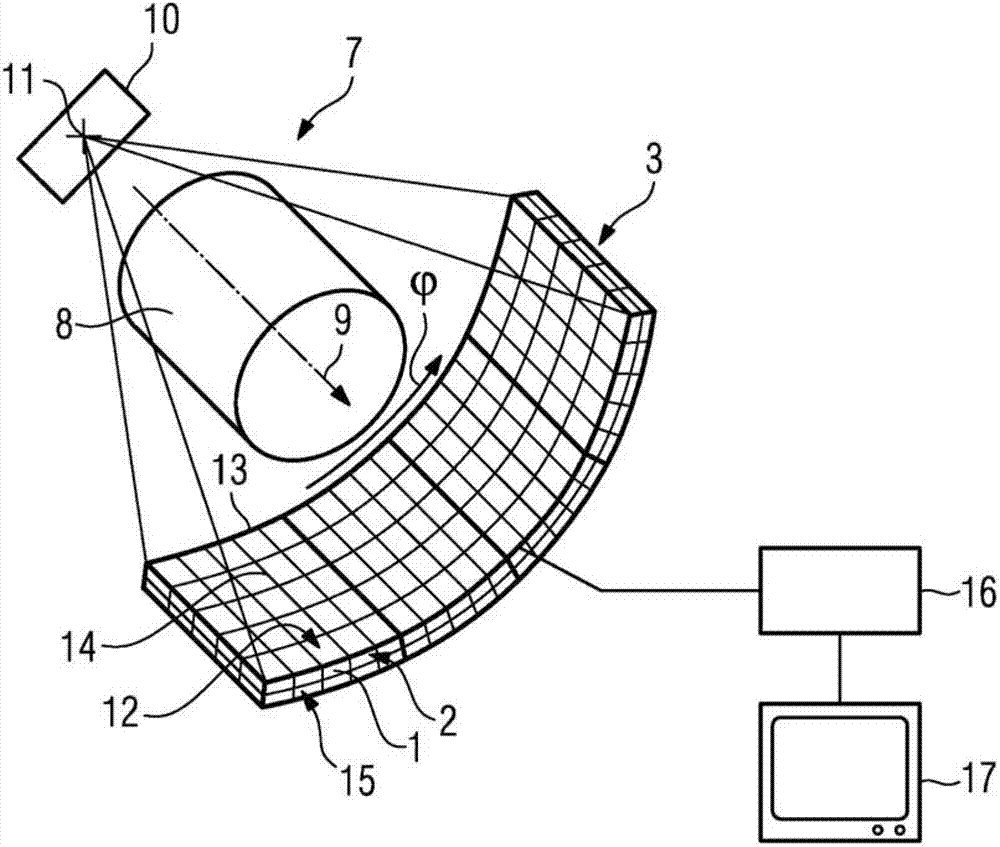

[0029] exist figure 1 The computed tomography system 7 is shown partly in perspective and partly in block diagram form. The computed tomography system 7 includes a patient table (not shown) for placing a patient 8 to be examined. Furthermore, a gantry (not shown) is included, which has the imaging system 10 , 3 mounted rotatably about the system axis 9 . The imaging system 10 , 3 has an x-ray tube 10 and a radiation detector 3 arranged opposite it, so that during operation x-rays emanating from a focal point 11 of the x-ray tube 10 pass through the patient 8 and reach the radiation detector 3 . The radiation detector 3 for the spatially resolved detection of x-ray radiation is divided into pixels 12, wherein groups of pixels are respectively located in The radiation detector modules 13 are formed in rows according to the lines marked in bold.

[0030] To convert the x-ray radiation into optically visible light, the radiation detector 3 has a scintillator 2 which is divided...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com