Prediction method of blast furnace gas generation and calorific value based on gas composition change

A technology of blast furnace gas and gas composition, applied in forecasting, data processing applications, instruments, etc., can solve the problems that the prediction accuracy is difficult to meet the actual production needs, the prediction results have large deviations, and the correlation is not clear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The specific embodiments provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

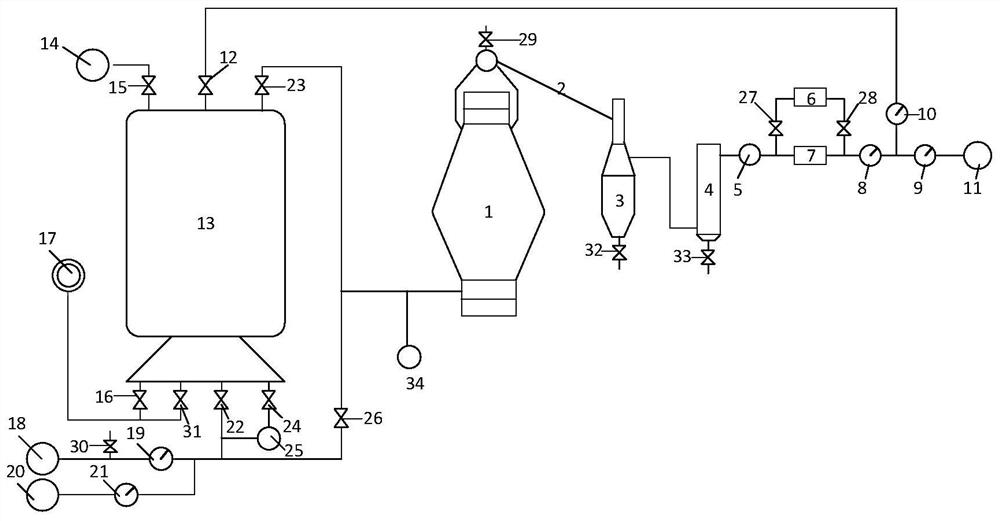

[0050] Such as figure 1 As shown, the blast furnace gas generated in the blast furnace (1) enters the gravity dust collector (3) through the raw gas downcomer (2), and after fine dust removal by the bag filter (4), passes through the gas composition analyzer (5) and enters the TRT The generator set (6) or the bypass valve group (7), after passing through the total gas flow orifice (8), are sent to the blast furnace gas pipe network (11) and through the gas flow orifice (9) respectively. 10), through the gas regulating valve (12), the blast furnace gas is sent into the hot blast stove (13); during the combustion period, the air is sent into the hot blast stove (13) by the combustion-supporting fan (14) through the air regulating valve (15), and the combustion waste gas Enter the chimney (17) through the flue valve (16); during the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com