Method for high-precision forecasting of blast furnace hot blast stove gas consumption amount

A hot blast stove and consumption technology, applied in forecasting, blast furnace, blast furnace details, etc., can solve problems such as staying at the level of theoretical research, publishing papers, difficult to apply, and discounting prediction accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

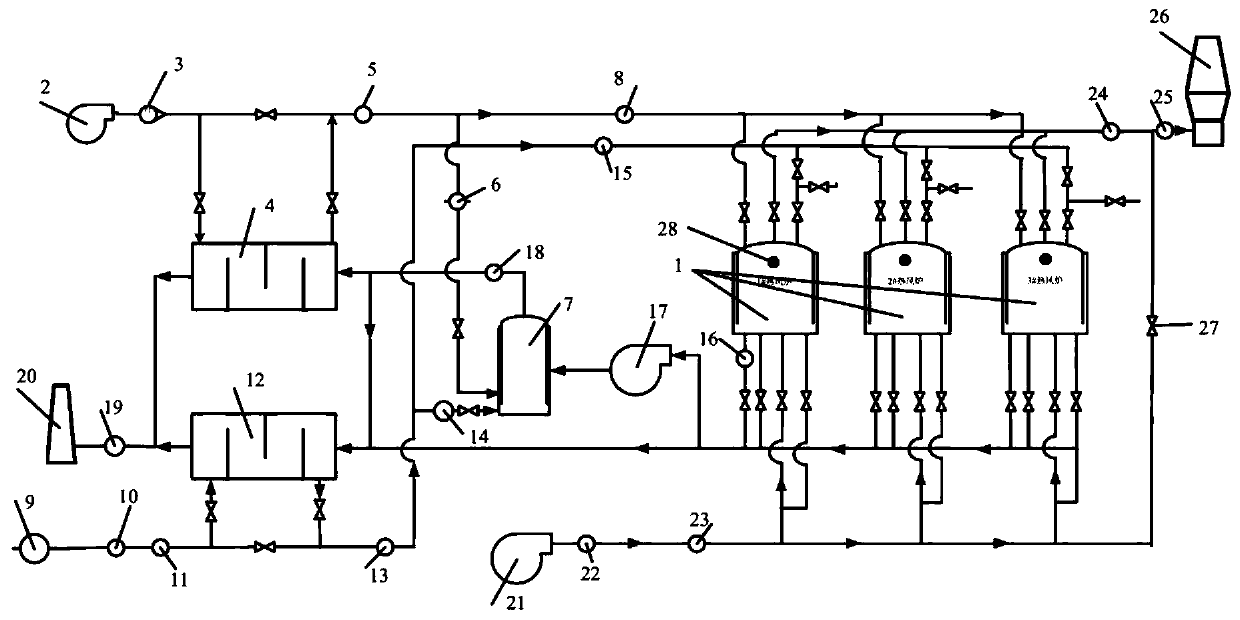

[0109] The specific embodiments provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

[0110] Such as figure 1 As shown, a blast furnace is usually equipped with 3 to 4 hot blast stoves, and the system of two firings and one delivery or two firings and two delivery systems is implemented. The hot blast stove (1) is in the combustion period: the cold air sent by the combustion-supporting fan (2) is sent to the air heat exchanger (4) through the air flow meter (3), and after the temperature is measured by the thermocouple (5), part of it passes through the air flow Meter (6) is sent to combustion furnace (7) for combustion support, and the other part is sent to hot blast stove (1) for combustion support through air flow meter (8); coal gas is sent into by gas pipe network (9), passes through gas flow meter (10) and The gas calorific value instrument (11) is preheated by the gas heat exchanger (12), and after the temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com