Method for determining oxide component content of cement raw meal by near infrared diffuse reflection spectrum

A technology of near-infrared spectrometer and cement raw material, which is applied in the direction of material analysis through optical means, material analysis using wave/particle radiation, and measuring devices, etc. It can solve the problems of large fluctuations in cement quality, long time consumption, and adjustment of raw material ratio. Hysteresis and other problems can be eliminated to achieve the effects of eliminating noise and useless information, accurate measurement results, and improving prediction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

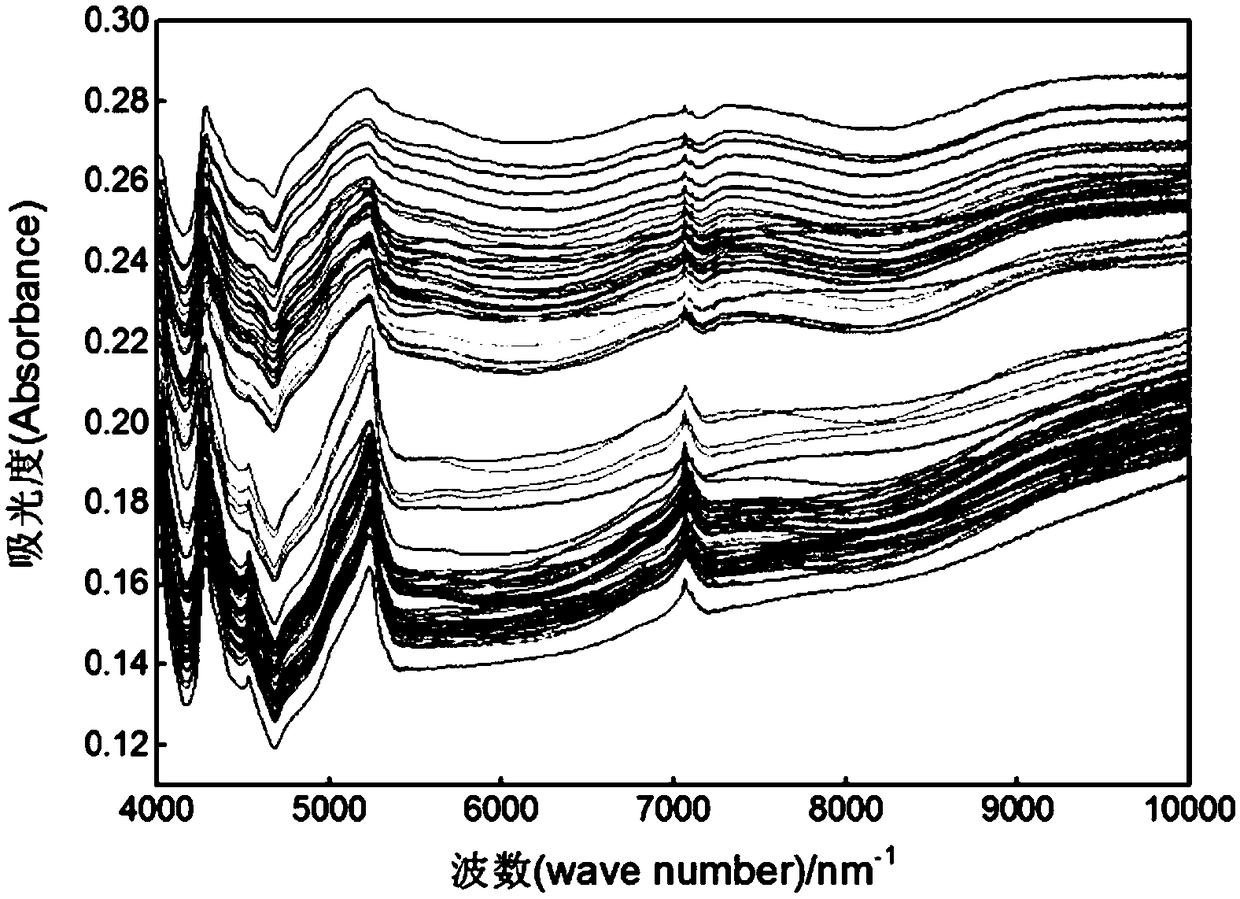

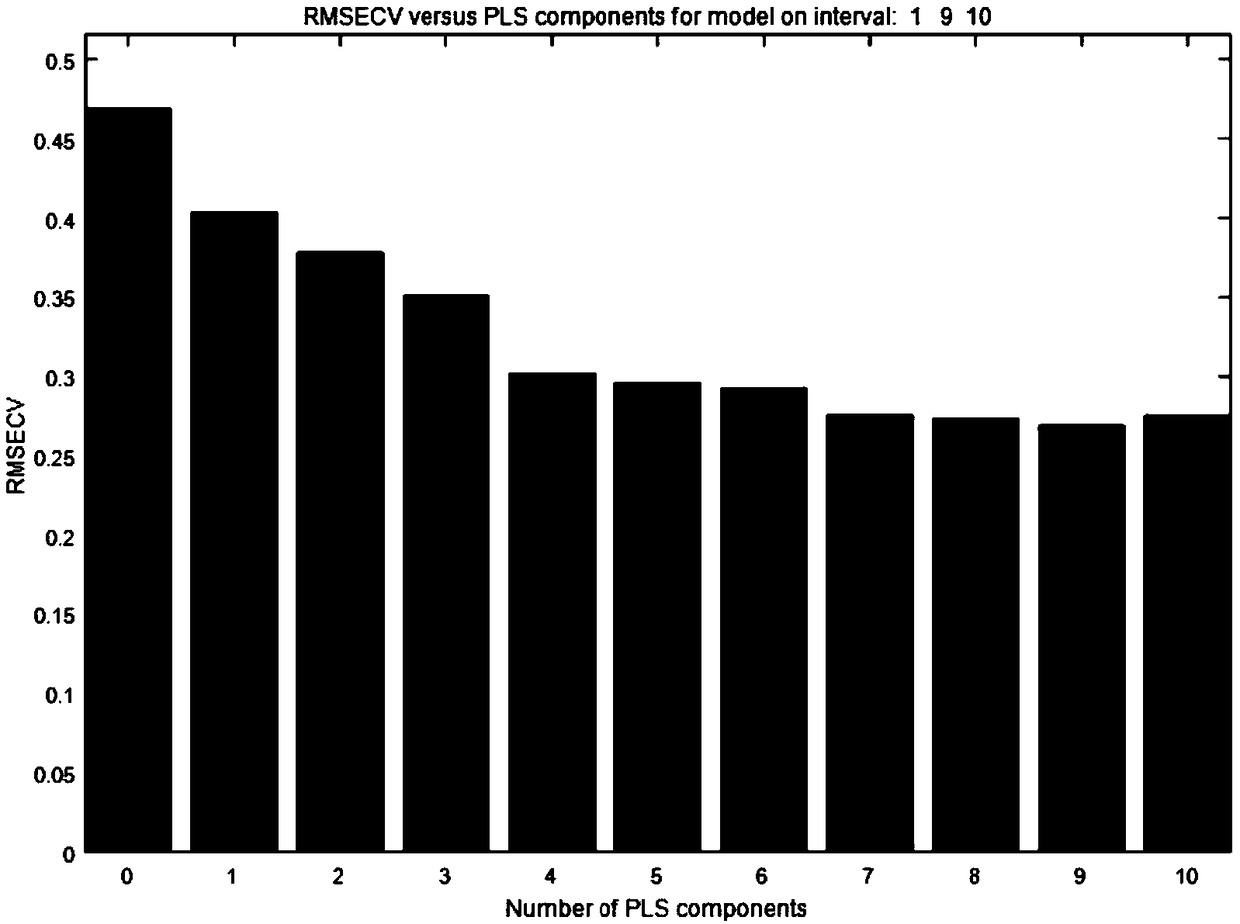

[0082] Described in this embodiment is a kind of near-infrared diffuse reflectance spectroscopy combined with cooperative interval partial least squares method to quickly determine the main components of cement raw meal (CaO, SiO 2 、Al 2 o 3 , Fe 2 o 3 ) content, the method comprises the following steps:

[0083] (1) Collect cement raw meal samples;

[0084] Collect powdered cement raw material samples from the production line of Shandong Qufu Zhonglian Cement Plant through the automatic sampler at the material sampling port;

[0085] (2) Determination of the main components (CaO, SiO, 2 、Al 2 o 3 , Fe 2 o 3 ) content, to provide standard data for subsequent modeling using the cooperative interval partial least squares method;

[0086] Deeply grind the powdered cement raw meal sample; take 100g of the ground cement raw meal sample and put it into a mold to press it into a cake; put the pressed cake sample into an X-ray fluorescence analyzer to measure the amount of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com