Floating floor slab thermal insulation sound insulation system and laying method thereof

A floating floor and sound insulation technology, applied in the directions of heat preservation, sound insulation, building components, etc., can solve the problems of poor environmental protection effect and high cost of floating floor, and achieve the effect of remarkable economy, ensuring project quality and advanced technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

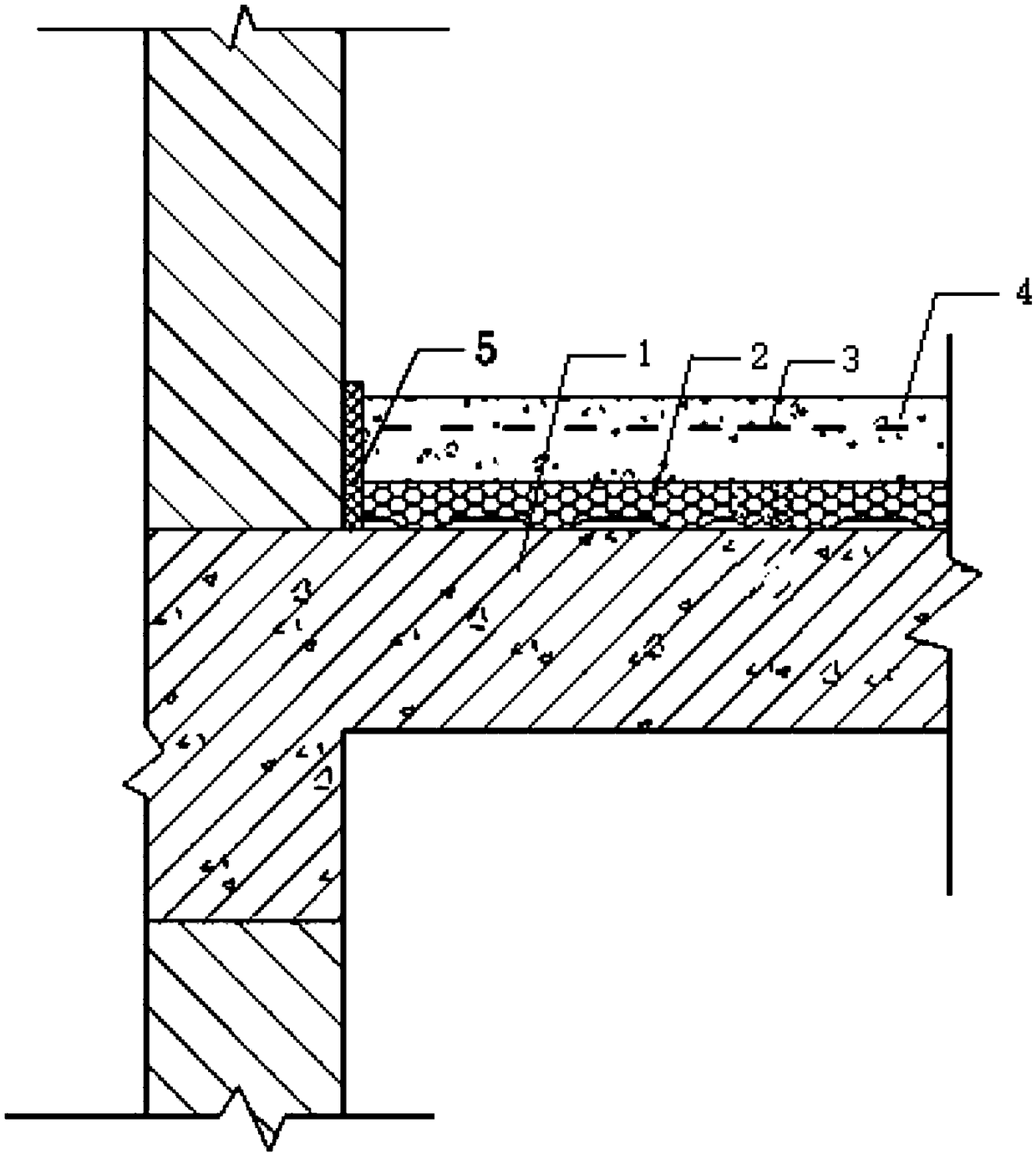

[0043] See figure 1 , a thermal insulation and sound insulation system for a floating floor slab disclosed in this embodiment, comprising a thermal insulation and sound insulation board 2 and a fine stone concrete protective surface layer 4 sequentially laid on the upper surface of the concrete floor base 1 from bottom to top, and the fine stone The steel wire mesh sheet 3 for preventing the cracking of the fine stone concrete protective surface layer 4 is arranged in the concrete protective surface layer 4 .

[0044] In this embodiment, a vertical sound insulation sheet 5 is also provided, and the vertical sound insulation sheet 5 is arranged between the heat insulation and sound insulation board 2, the fine stone concrete protective surface layer 4 and the wall, and is used to block the sound bridge. .

[0045] See Figure 5 , Image 6 , further, the heat insulation and sound insulation board 2 includes a substrate and a non-woven fabric layer 12, and the non-woven fabric...

Embodiment 2

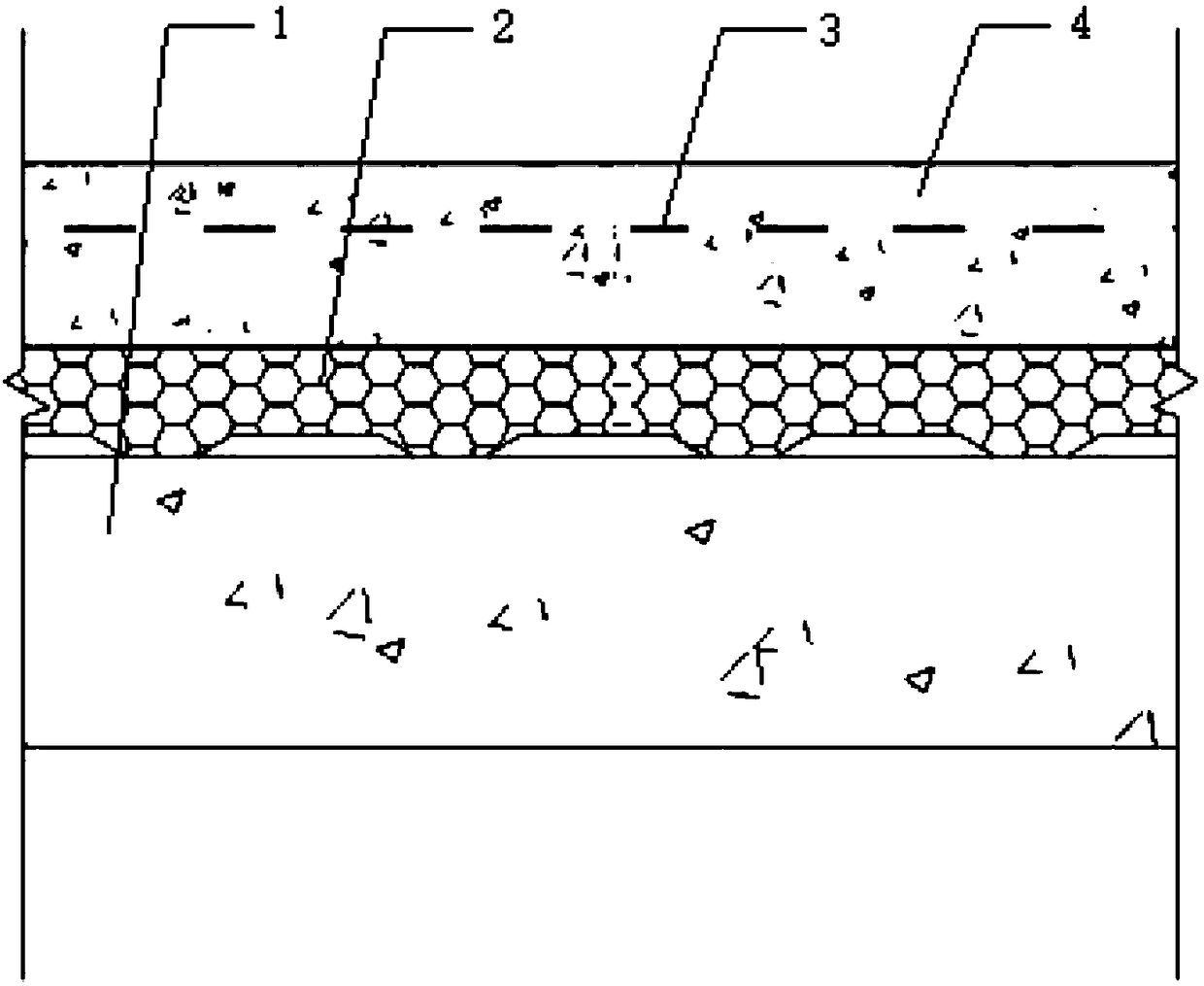

[0049] See figure 2 , which is the basic structural diagram of the household (inter-floor) floor of the floating floor thermal insulation system. A thermal insulation and sound insulation system for a floating floor slab disclosed in this embodiment comprises a thermal insulation and sound insulation board 2 and a fine stone concrete protective surface layer 4 that are sequentially laid on the upper surface of the concrete floor base 1 from bottom to top. The steel wire mesh sheet 3 for preventing the cracking of the fine stone concrete protective surface layer 4 is arranged in the protective surface layer 4 .

[0050] See Figure 5 , Image 6 , further, the heat insulation and sound insulation board 2 includes a substrate and a non-woven fabric layer 12, and the non-woven fabric layer 12 covers the top surface of the substrate. Furthermore, a concave-convex corrugated structure 13 is provided on the bottom surface of the substrate.

[0051] Wherein, the substrate is an E...

Embodiment 3

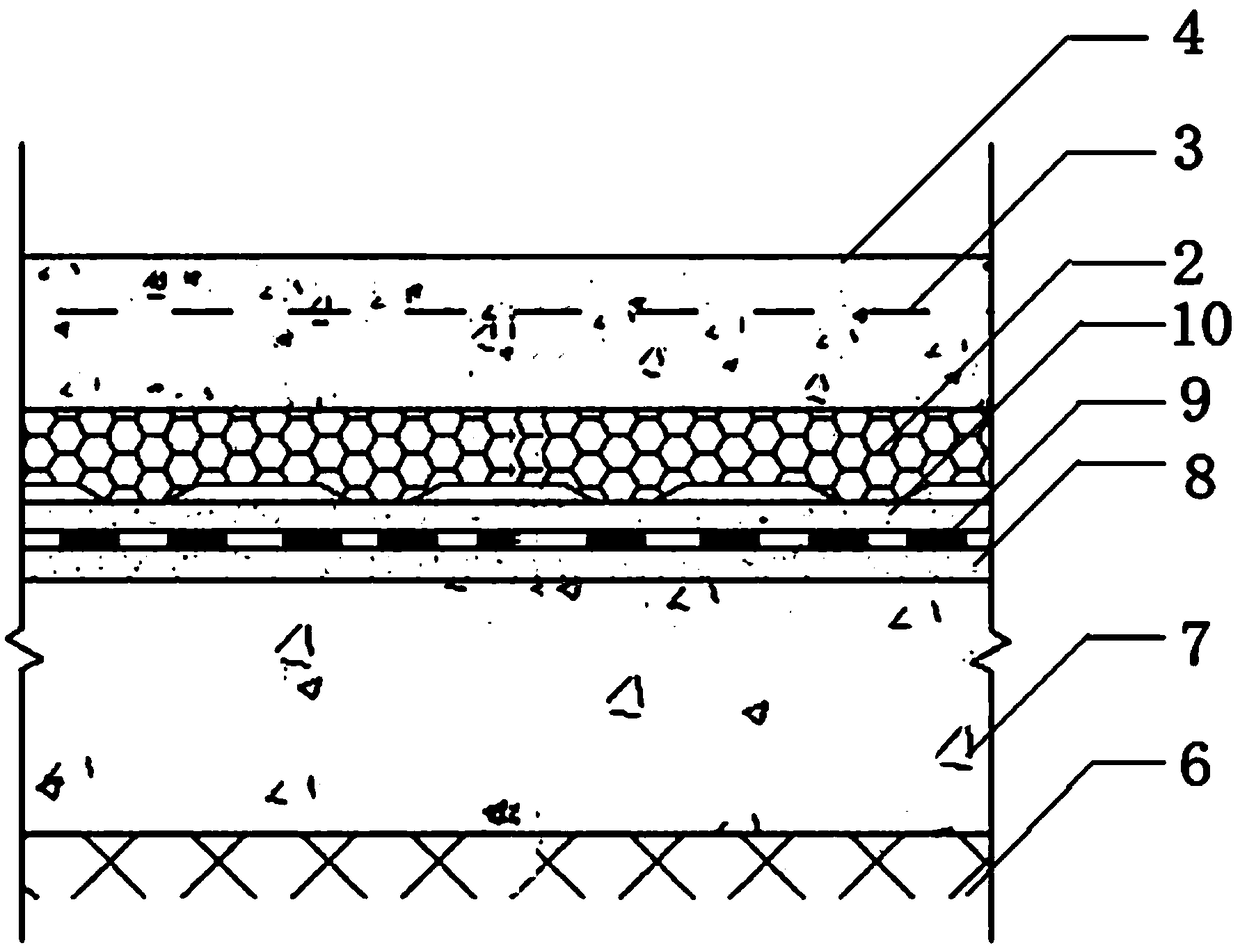

[0053] See image 3 , is the ground structure diagram of the floating floor thermal insulation system contacting the soil. A thermal insulation and sound insulation system for a floating floor slab disclosed in this embodiment comprises a thermal insulation and sound insulation board 2 and a fine stone concrete protective surface layer 4 that are sequentially laid on the upper surface of the concrete floor base 1 from bottom to top. The steel wire mesh sheet 3 for preventing the cracking of the fine stone concrete protective surface layer 4 is arranged in the protective surface layer 4 . When contacting the soil, it is necessary to tamp plain soil 6 at the bottom layer, followed by plain concrete 7, cement mortar leveling layer 8, moisture-proof layer 9, cement leveling layer 10, thermal insulation and sound insulation board 2, steel wire mesh sheet 3, fine Stone concrete protection surface 4.

[0054] See Figure 5 , Image 6 , further, the heat insulation and sound insul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com