Novel aramid-paper-based copper-clad plate and preparation method thereof

A technology of aramid paper and copper clad laminate, applied in chemical instruments and methods, paper/cardboard layered products, paper, etc., can solve problems such as poor thermal conductivity, achieve small thermal expansion coefficient, increase strength, and good electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

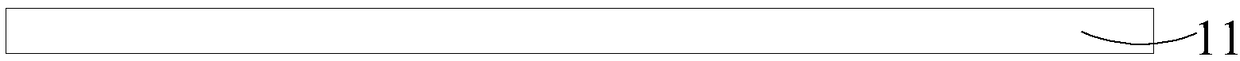

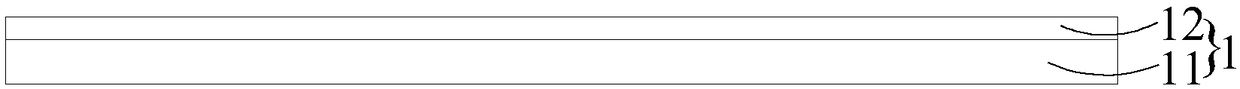

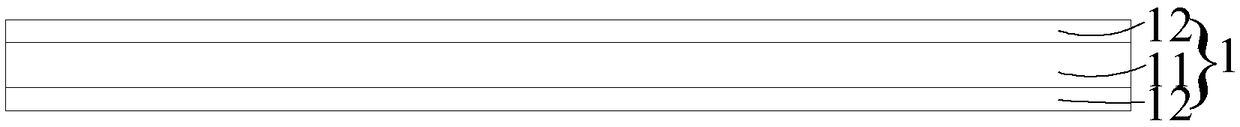

Image

Examples

preparation example Construction

[0049] In one embodiment, the preparation method of the novel aramid paper-based copper-clad laminate includes at least the following steps:

[0050] Step S01. Deflaking the para-aramid chopped fibers to make slurry A;

[0051] Step S02. Deflaking the para-aramid fibrid fibers, and adding silicon nitride fibers to make slurry B;

[0052] Step S03. The slurry A and the slurry B are mixed, and additives are added, followed by papermaking and hot rolling to obtain modified para-aramid paper;

[0053] Step S04. Perform mixing treatment of high Tg resin, filler, and surface modifier to obtain a resin mixture, mix the resin mixture with the curing agent to obtain an impregnation solution, and mix the modified parasite obtained in step S03 Immersing the aramid paper in the impregnation solution, and drying to form a resin composite layer stacked on the surface of the modified para-aramid paper to obtain a prepreg;

[0054] Step S05. Stack several semi-solid sheets to obtain a subst...

Embodiment 1

[0067] A preparation method of a novel aramid paper-based copper-clad laminate, the steps of which are as follows:

[0068] (1) Preparation of modified para-aramid paper: provide 10 parts of para-aramid chopped fiber, 90 parts of para-aramid precipitated fiber, and 15 parts of silicon nitride fiber; wherein the average length of the silicon nitride fiber is 100 μm ;

[0069] The above-mentioned para-aramid chopped fibers are decompressed with a hydraulic deflagging machine to obtain a slurry A with a concentration of 1 wt %;

[0070] The above-mentioned para-aramid precipitated fiber was decompressed with a hydraulic deflagging machine, and silicon nitride fiber was added, and after polishing and pulping, the beating degree was controlled to be about 75°SR, and a slurry B with a concentration of 2wt% was obtained;

[0071] The slurry A and the slurry B are mixed evenly in the batching tank, transferred to the pulp stabilization box, and polyethylene oxide is added therein, af...

Embodiment 2

[0075] A preparation method of a novel aramid paper-based copper-clad laminate, the steps of which are as follows:

[0076] (1) Preparation of modified para-aramid paper: provide 90 parts of para-aramid chopped fiber, 10 parts of para-aramid precipitated fiber, and 15 parts of silicon nitride fiber; wherein the average length of the silicon nitride fiber is 150 μm ; The above-mentioned para-aramid chopped fibers are decompressed with a hydraulic deflagging machine to obtain a slurry A with a concentration of 1 wt %;

[0077] The above-mentioned para-aramid precipitated fiber was decompressed with a hydraulic deflagging machine, and silicon nitride fiber was added, and after polishing and pulping, the beating degree was controlled to be about 75°SR, and a slurry B with a concentration of 2wt% was obtained;

[0078] The slurry A and the slurry B are mixed evenly in the batching tank, transferred to the pulp stabilization box, and polyethylene oxide is added therein, after paperm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com