A kind of biomedical coating based on graphene and titanium dioxide and preparation method thereof

A titanium dioxide, biomedical technology, applied in the field of biomedicine, can solve the problems of poor responsiveness of biologically active cells, achieve good photoelectric effect, improve adhesion, and improve biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) At first polymethyl methacrylate (PMMA) solution is spin-coated to the graphene surface of graphene / copper sheet with 4000rpm, and spin-coating time is 40s; Then copper sheet is etched in ammonium persulfate solution, at room temperature , the copper sheet was etched for 24 hours; the graphene / PMMA film was rinsed with deionized water and then transferred to the surface of the pickled Ti substrate (100 μm). After natural drying, the PMMA was removed with acetone and dissolved at 60°C for 5 minutes.

[0023] (2) After the Graphene / Ti substrate was rinsed and dried, the TiO 2 Sol dip coating onto graphene surface of Graphene / Ti substrate, TiO 2 Sol 0.1g / mL, dipping density 200mL / m 2 .

[0024] (3) Water evaporates naturally for 1 day, forming TiO on the surface of graphene 2 nano dots.

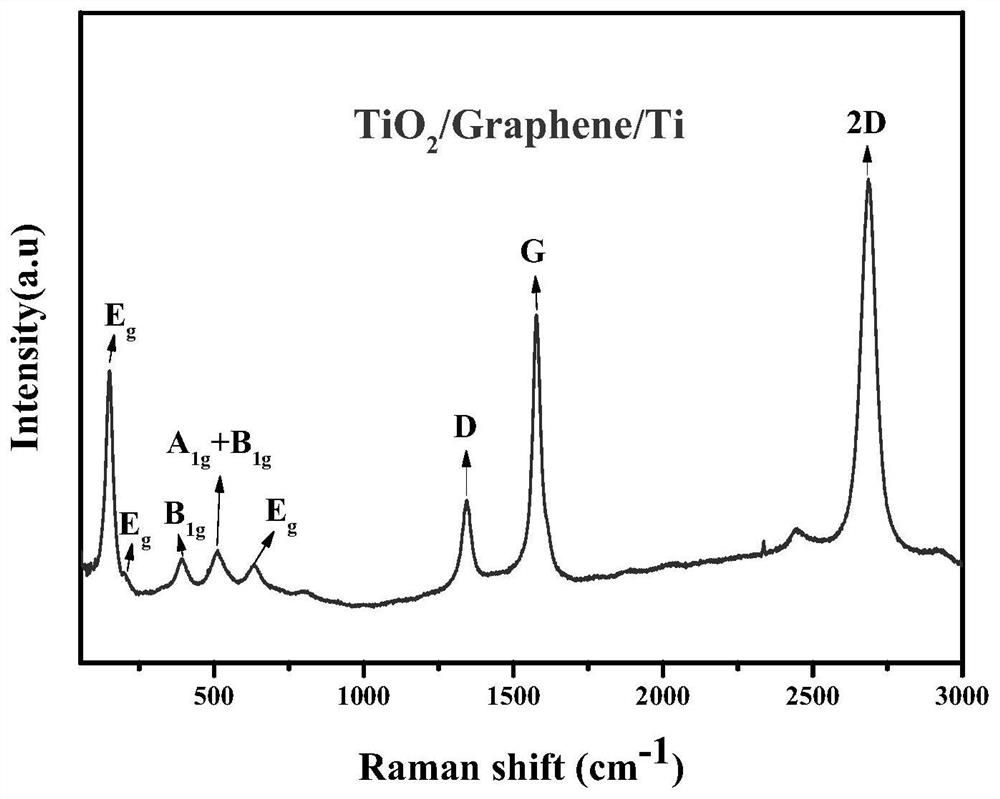

[0025] The TiO produced in this example 2 / Surface topography and mapping images of graphene / Ti substrate surface scanning electron microscope (SEM) test figure 2 As shown, the...

Embodiment 2

[0027] (1) At first polymethyl methacrylate (PMMA) solution is spin-coated to the graphene surface of graphene / copper sheet with 3000rpm, spin-coating time is 50s; Then copper sheet is etched in ammonium persulfate solution, at room temperature , the copper sheet was etched for 24 hours; the graphene / PMMA film was rinsed with deionized water and transferred to the surface of an acid-washed Ti substrate (1000 μm). After natural drying, the PMMA was removed with acetone and dissolved at 80 ° C for 1 min.

[0028] (2) After the Graphene / Ti substrate was rinsed and dried, the TiO 2 Sol dip coating onto graphene surface of Graphene / Ti substrate, TiO 2 Sol 0.05g / mL, dip coating density 500mL / m2 .

[0029] (3) Water evaporates naturally for 3 days, forming TiO on the surface of graphene 2 nano dots.

[0030] The TiO produced in this example 2 TiO / graphene / Ti substrate 2 The nanometer dots are uniformly distributed, the nanometer size of the titanium dioxide is 50-250nm, and the ...

Embodiment 3

[0032] (1) At first polymethyl methacrylate (PMMA) solution is spin-coated to the graphene surface of graphene / copper sheet with 5000rpm, and the spin-coating time is 30s; Then copper sheet is etched in ammonium persulfate solution, at room temperature , the copper sheet was etched for 24 hours; the graphene / PMMA film was rinsed with deionized water and transferred to the surface of an acid-washed Ti substrate (500 μm). After natural drying, the PMMA was removed with acetone and dissolved at 70°C for 3 minutes.

[0033] (2) After the Graphene / Ti substrate was rinsed and dried, the TiO 2 Sol dip coating onto graphene surface of Graphene / Ti substrate, TiO 2 Sol 0.2g / mL, dipping density 100mL / m 2 .

[0034] (3) Water evaporates naturally for 2 days, forming TiO on the surface of graphene 2 nano dots.

[0035] The TiO produced in this example 2 TiO / graphene / Ti substrate 2 The nano-dots are evenly distributed, the titanium dioxide nano-size is 50-250 nm, and the titanium diox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com