STA-20, novel molecular sieve framework type, methods of preparation and use

A technology of STA-20 and SAPOSTA-20, applied in STA-20

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0219] Embodiment 1 synthetic SAPO STA-20 type

[0220] A reaction gel was prepared with 2% SAPO-AFX (seeded) in a 125 mL pressure vessel with a molar composition:

[0221] 0.10 SiO 2 :1 Al(OH) 3 :0.90H 3 PO 4 :40H 2 O: 0.10 DiDABCO-C6: 0.42 Trimethylamine: 0.08 Tetrabutylammonium hydroxide.

[0222] The reagents used and the order of addition are:

[0223] a) Add the required amount of phosphoric acid (H 3 PO 4 85% by weight, Alfa Chemicals) into a 100ml container by weight.

[0224] b) Add required amount of fumed silica (Cabosil) and water to the phosphoric acid and stir.

[0225] c) Add the required amount of aluminum hydroxide (Al(OH) 3 , Alfa Aesar) was added to the above mixture.

[0226] d) After stirring for 10 minutes, 1,1'-(1,6-hexanediyl)bis(4-aza-1-azoniumbicyclo[2.2.2]octane)dibromide (Alfa Chemicals) was added .

[0227] e) Trimethylamine (Alfa Chemicals, 85% by weight) was added to the above solution, and the mixture was stirred for 10 minutes.

...

Embodiment 2

[0235] Embodiment 2 activates SAPO STA-20 (remove template agent)

[0236] The fabricated (templated) material of Example 1 was activated by calcination in air. The material was heated at 2°C / minute to 110°C and held at 110°C for 10 hours, then heated at 5°C / minute to 450°C and held at 450°C for 16 hours. The material was then heated to 550°C at 5°C / min and held at 550°C for 16 hours.

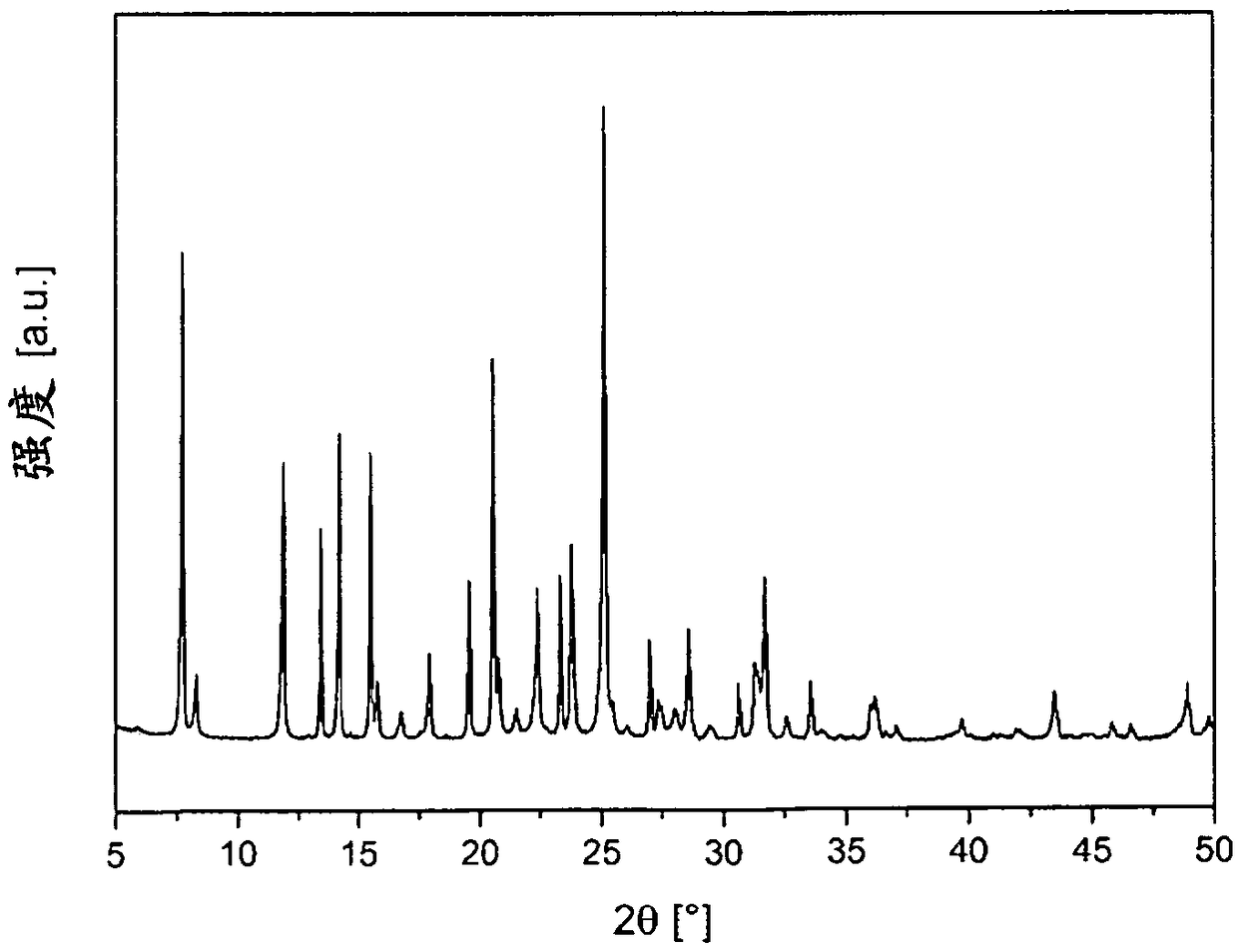

[0237] The powder XRD pattern is shown in image 3 , including the diffraction peaks of Table 5. Powder XRD analysis showed that the product was phase pure STA-20.

[0238] table 5

[0239]

[0240]

[0241] (a) = ±0.2

Embodiment 3

[0242] Embodiment 3 synthetic SAPO STA-20 type

[0243] A reaction gel was prepared following the same procedure described in Example 1 with 2% SAPO-AFX (seed) in a 125 mL pressure vessel, which had a molar composition:

[0244] 0.20 SiO 2 :1 Al(OH) 3 :0.80H 3 PO 4 :40H 2 O: 0.10 DiDABCO-C6: 0.42 Trimethylamine: 0.08 Tetrabutylammonium hydroxide.

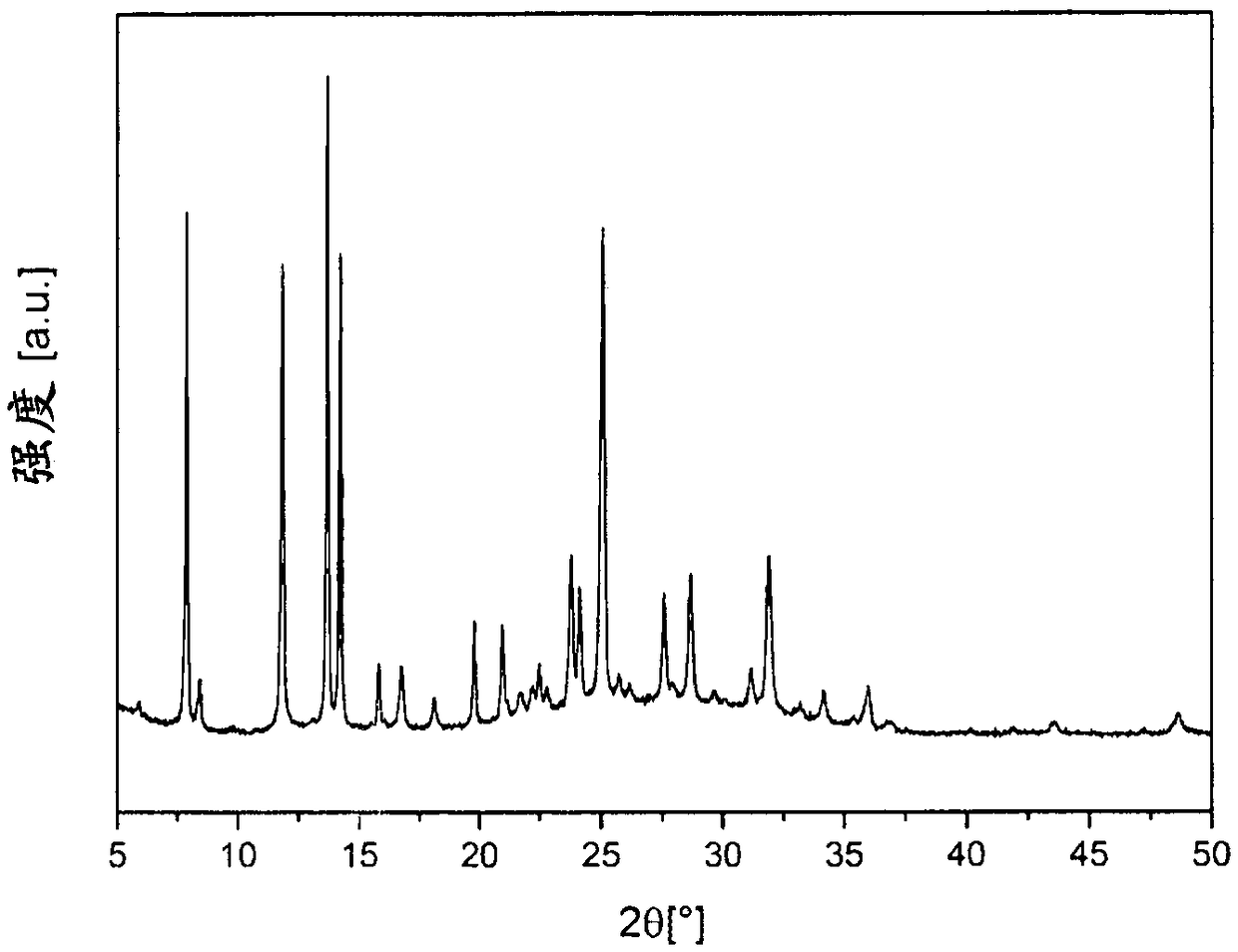

[0245] The XRD of the dried product was shown at Figure 4 middle.

PUM

| Property | Measurement | Unit |

|---|---|---|

| process yield | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com