A low-temperature lithium ion battery electrolyte and lithium ion battery based on surfactant

A surfactant and lithium-ion battery technology, applied in the field of lithium-ion batteries, can solve problems such as difficult to maintain lithium ion migration rate, reduce reaction kinetics rate, low conductivity, etc., to achieve good performance and ensure low impedance characteristics , the effect of high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

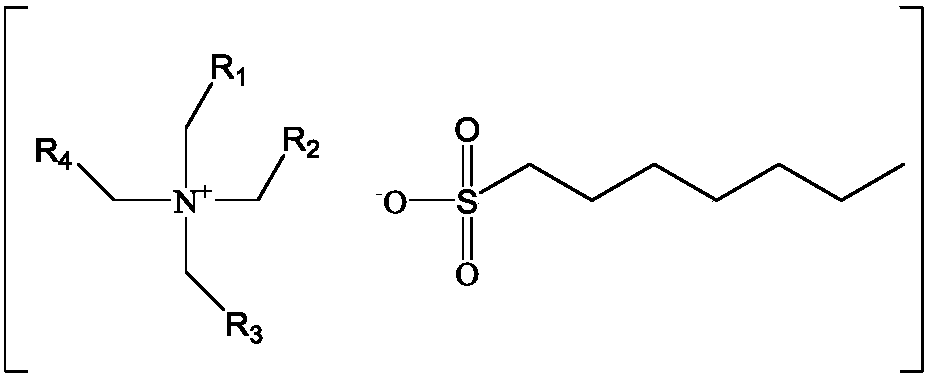

[0022] Mix the mixed solvent of ethylene carbonate, dimethyl carbonate, ethyl methyl carbonate and ethyl propionate at a mass ratio of 30:30:30:10, and then fully dissolve lithium hexafluorophosphate in the premixed solvent, then add mass The fraction is 2.5% vinylene carbonate and 2.5% vinyl sulfate, and finally add 0.2% surfactant tetraethylammonium octanesulfonate, and mix to obtain electrolyte 1; wherein lithium hexafluorophosphate accounts for the mass ratio of the whole electrolyte 14%. The above steps were all performed in a glove box filled with inert gas.

Embodiment 2

[0024] Mix the mixed solvent of ethylene carbonate, dimethyl carbonate, ethyl methyl carbonate and ethyl propionate at a mass ratio of 20:40:20:10, and then fully dissolve lithium hexafluorophosphate in the premixed solvent, then add mass The fraction is 1% vinylene carbonate and 1% lithium bisfluorosulfonimide, and finally add 0.5% surfactant tetraethylammonium octanesulfonate, and mix to obtain electrolyte 2; wherein lithium hexafluorophosphate accounts for the whole The electrolyte mass ratio is 14%. The above steps were all performed in a glove box filled with inert gas.

Embodiment 3

[0026] Mix the mixed solvent of ethylene carbonate, dimethyl carbonate, ethyl methyl carbonate and ethyl propionate at a mass ratio of 20:50:20:1, and then fully dissolve lithium hexafluorophosphate in the premixed solvent, then add mass The fraction is 2% vinylene carbonate and 1% vinyl sulfate, 1% lithium bisfluorosulfonimide, and finally add 0.2% surfactant tetraethylammonium heptadecafluorooctanesulfonate, mix Electrolyte 3 was obtained; the mass ratio of lithium hexafluorophosphate to the whole electrolyte was 14%. The above steps were all performed in a glove box filled with inert gas.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com