Determination method for nickel content in ferrochrome-nickel anti-corrosion alloys

A technology of corrosion-resistant alloy and determination method, which is applied in the field of chemical analysis and can solve the problems of numerous reagents, cumbersome operation process, long analysis period, etc.

Inactive Publication Date: 2018-12-21

SHANXI TAIGANG STAINLESS STEEL CO LTD

View PDF6 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This method completely adopts the traditional chemical wet analysis, which uses a lot of reagents, the operation process is cumbersome, and the analysis period is long, which cannot meet the needs of rapid and accurate detection of nickel content.

[0003] In view of this, it is necessary to provide a method that can quickly and accurately detect the nickel content in view of the problems that the traditional dimethylglyoxime gravimetric method uses a variety of reagents, cumbersome operation process, and long analysis period, which cannot meet the needs of rapid and accurate detection of nickel content. Determination method for detecting nickel content in iron-chromium-nickel corrosion-resistant alloy

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

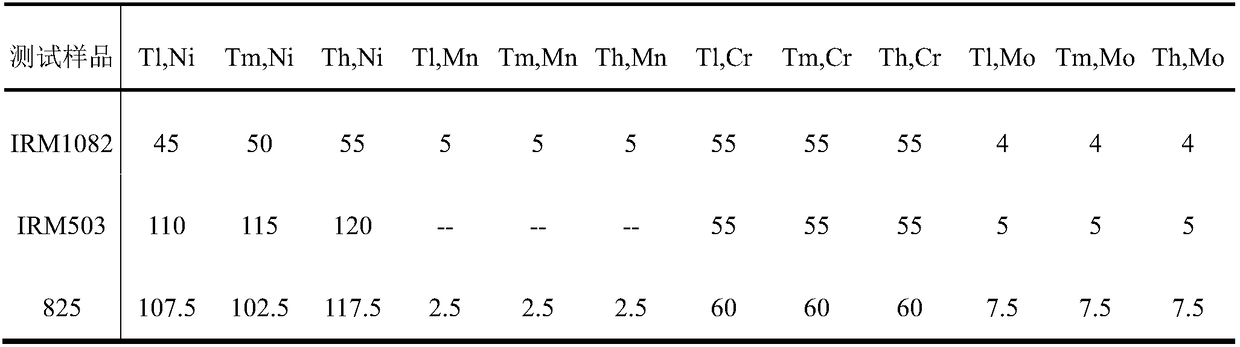

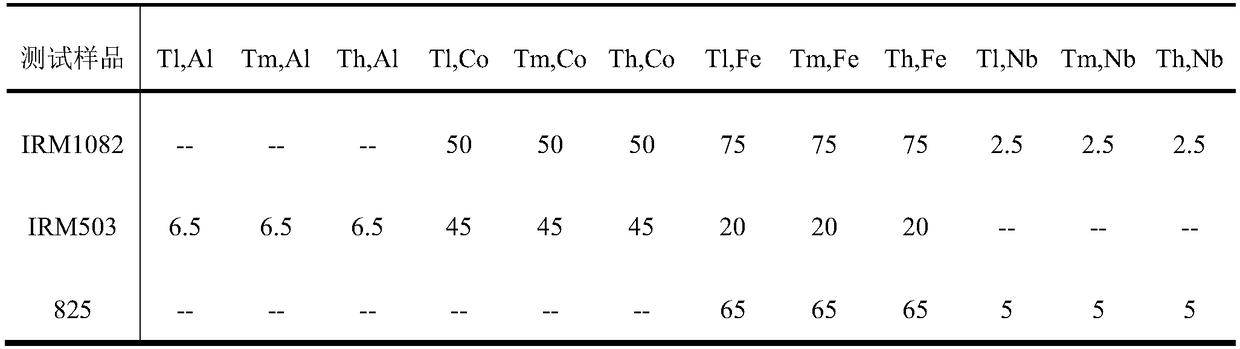

[0034] Weigh 0.2500g of the sample to be tested in the Erlenmeyer flask, add 10mL of HCl and add HNO drop by drop 3 Heat and dissolve on the electric heating plate at low temperature. After the dissolution is complete, remove and cool, transfer to a 250mL volumetric flask, accurately add 10mL yttrium standard solution with a mass concentration of 50mg / L, dilute with deionized water to volume, and shake well , to prepare a sample solution.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

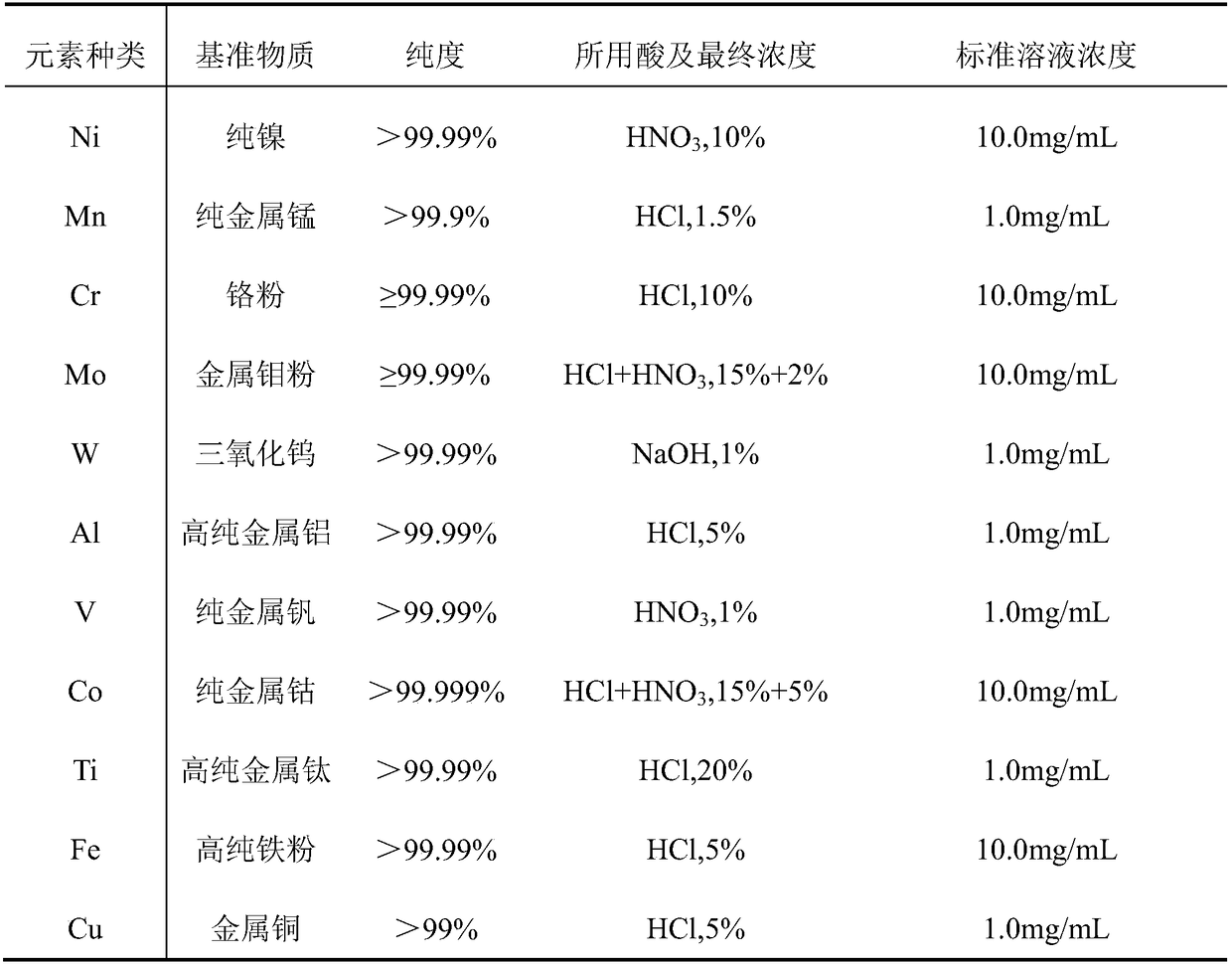

The invention discloses a determination method for nickel content in ferrochrome-nickel anti-corrosion alloys. The determination method comprises the following steps that alloy samples to be tested are weighed, hydrochloric acid is added, and nitric acid is dropped in drops by drops on an electrothermal plate for heating and dissolution, after dissolution and cooling are completed, a yttrium standard solution is added for constant volume, and a sample solution is prepared; high-purity metals and / or metal oxides containing metallic elements in the alloy samples to be tested are / is used as raw materials to prepare a nickel standard solution and other metallic element standard solutions containing various other metallic elements contained in the alloy samples to be tested, a calibration curvesolution is prepared by the nickel standard solution and other metal element standard solutions; the sample solution and the standard curve solution are introduced into an inductively coupled plasmaemission spectrometer to measure the signal strength, a standard curve is drawn according to the measured results and the nickel content in the samples is calculated according to the standard curve. The determination method for the nickel content in the ferrochrome-nickel anti-corrosion alloys is less in used reagents, simple in operation, short in analysis period, and can quickly detect the nickel content.

Description

technical field [0001] The invention belongs to the technical field of chemical analysis, in particular to a method for determining alloys, in particular to a method for determining nickel content in iron-chromium-nickel corrosion-resistant alloys. Background technique [0002] Iron-chromium-nickel corrosion-resistant alloy is a composite alloy composed of iron, chromium, nickel and other alloying elements. It is mainly used in electronics, chemical industry, machinery, medical treatment, energy development, navigation, aviation and aerospace and other departments. The current inspection of nickel content in iron-chromium-nickel corrosion-resistant alloys usually uses "GB / T 223.25-94 Chemical Analysis Methods for Iron, Steel and Alloys - Determination of Nickel Content by Diacetyl Oxime Gravimetric Method" to determine nickel content, using hydrochloric acid, nitric acid, hydrogen fluoride Acid decomposition, perchloric acid fuming, using tartaric acid (citric acid) as a com...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N21/73

CPCG01N21/73

Inventor 赵艳兵樊鑫曹吉祥

Owner SHANXI TAIGANG STAINLESS STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com