High-precision and wide-size particle field measurement method

A measurement method and particle field technology, applied in the direction of measurement devices, particle size analysis, particle and sedimentation analysis, etc., can solve the problems of difficult particle field measurement and simultaneous recording, and achieve good fringe contrast, high brightness, and high measurement The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

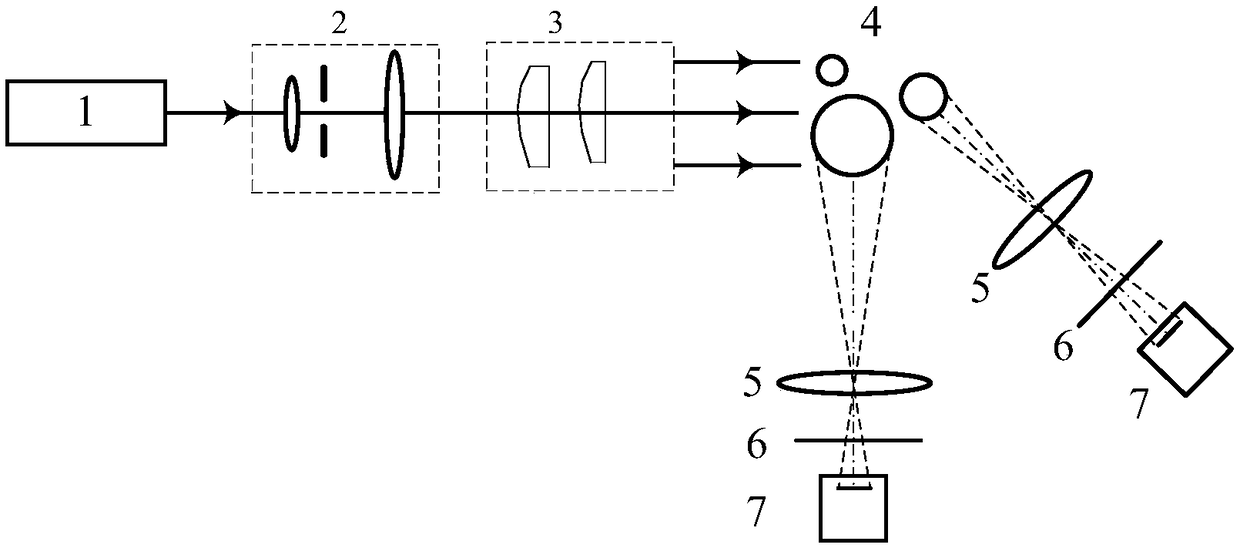

[0029] A high-precision wide-size particle field measurement method, see Figure 1-Figure 4 , the measurement method includes the following steps:

[0030] 1. Build the optical system

[0031] according to figure 1 The optical path system shown is constructed, including: a laser 1 , a beam expander collimator system 2 , a beam compression system 3 , a particle field 4 , an imaging lens 5 , a polarizer 6 , and a CCD 7 .

[0032] Laser 1 is a vertically polarized semiconductor laser with a wavelength of λ=532nm and a maximum power of 1.5W. The thin beam emitted by the laser 1 is expanded, filtered, and collimated by the beam expander and collimator system 2, and then compressed into a sheet-like beam by the beam compression system 3 composed of two cylindrical lenses.

[0033] The imaging lens 5 is a Nikon 50mmf / 1.8D fixed-focus lens, the number of pixels of the CCD 7 is 2448×2048, and the pixel size is 6.45 μm×6.45 μm. The imaging lens 5 collects the scattered light of the ...

Embodiment 2

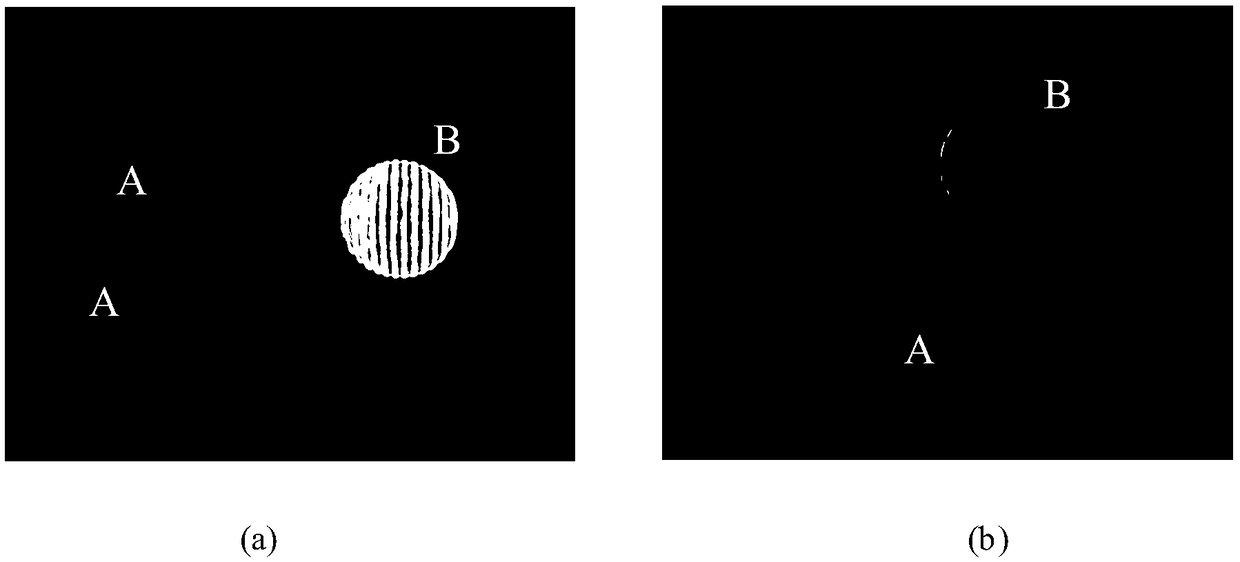

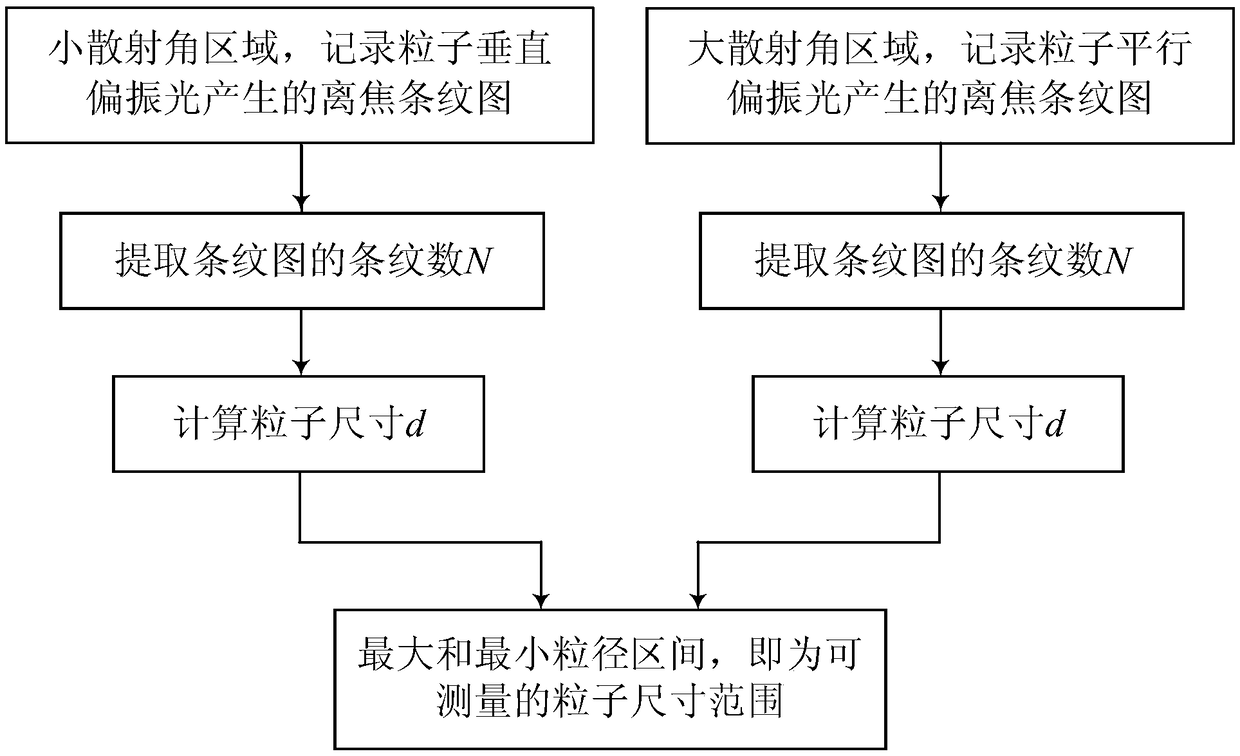

[0038] according to image 3 The flow chart was simulated, Figure 4 A set of simulation experiment results are given. Figure 4 (a) is the simulation result when the scattering angle is 70° and the scattered light is vertically polarized light, the measurable particle size range is 10 μm-100 μm, Figure 4 (b) is the simulation result when the scattering angle is 85° and the scattered light is parallel polarized light. The measurable particle size range is 30 μm-600 μm. right Figure 4 The system corresponding to (a) is more suitable for the measurement of small particle size particles, and the fringe frequency of the fringe pattern cannot be extracted for particles with a particle size of 200 μm and 250 μm. right Figure 4 The system corresponding to (b) is more suitable for the measurement of large particle size particles, and the fringe frequency cannot be extracted from the fringe pattern with a particle size of 800 μm. combine Figure 4 (a) and Figure 4 (b) Corres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com