Temperature, pressure and humidity monitoring sensor

A humidity monitoring and sensor technology, which is applied to the casing of the measuring device and indicating the values of multiple variables at the same time, can solve the problem that the temperature, humidity and pressure environment sensor cannot output analog and digital signals at the same time, and achieves low power consumption and adaptability. Wide and full-featured effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the application and together with the embodiments of the present invention are used to explain the principle of the present invention and are not intended to limit the scope of the present invention.

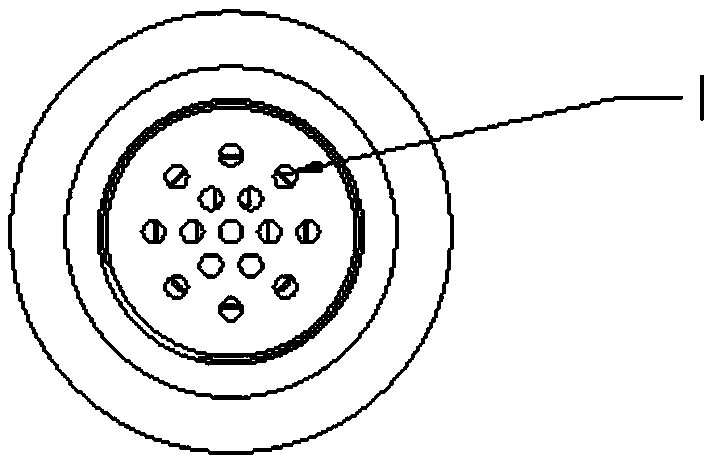

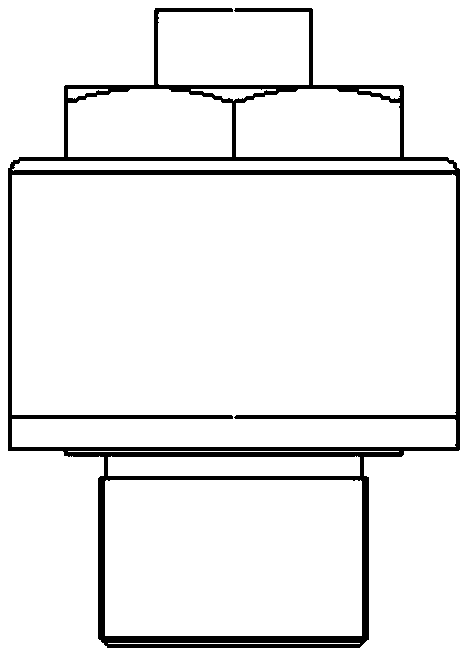

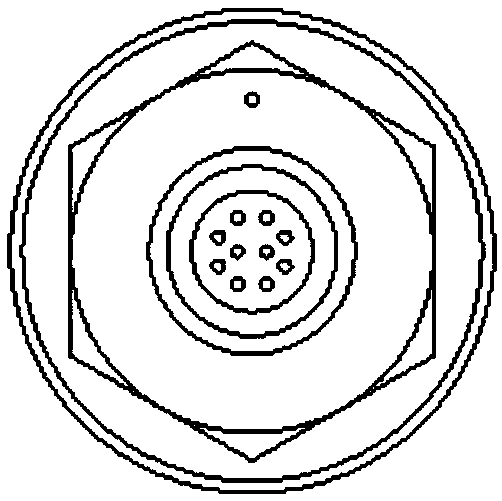

[0035] A specific embodiment of the present invention discloses a temperature, pressure and humidity monitoring sensor, such as Figure 1-5 As shown, it includes: housing (4), electrical connector (3), threaded base (8);

[0036] The threaded base and electrical connector are welded together with the housing to form a closed chamber; the electrical connector is used for data transmission between the sensor and external equipment; the threaded base is used to install the sensor;

[0037] A sensor module, a signal processing module, and a signal interface module are arranged inside the chamber;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com