Anti-typhoon structure of wind generating set

A wind turbine and anti-typhoon technology, applied in the direction of wind power generation, installation/supporting the configuration of wind turbines, etc., can solve the problems of affecting the daily operation efficiency of wind turbines, increasing investment and construction costs, and poor anti-typhoon effect. Daily operation efficiency, improvement of anti-typhoon effect, effect of reducing impact and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

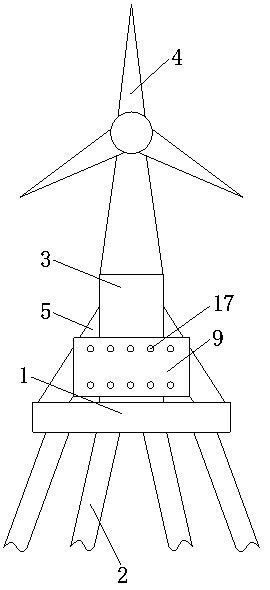

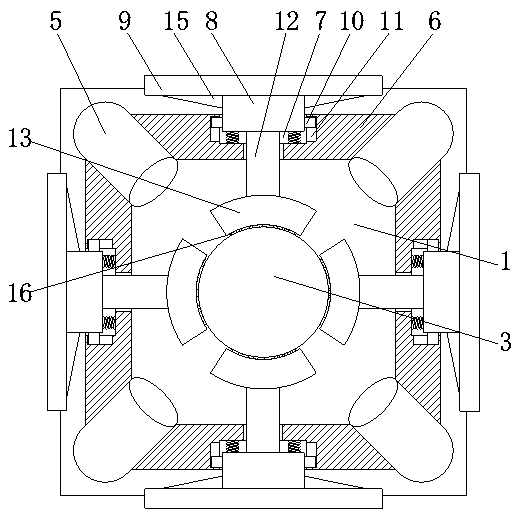

[0019] First implementation: see Figure 1-2 , an anti-typhoon structure of a wind power generating set, comprising a receiving plate 1, the bottom of the receiving plate 1 is fixedly connected with seabed anchors 2, the number of seabed anchors 2 is not less than four and equidistantly arranged around the receiving plate 1, at the edge of the bottom, the midpoint of the top of the receiving plate 1 is provided with a tower 3, the top of the tower 3 is provided with blades 4, and the top of the receiving plate 1 is fixedly connected with the main support column 5, and the number of the main support columns 5 is Four of them are respectively fixedly connected to the four corners of the top of the receiving plate 1, the side of the main support column 5 close to the tower 3 is fixedly connected to the tower 3, and the adjacent two main support columns 5 are fixedly connected by a connecting block 6 A groove 7 is opened at the midpoint of the connection block 6 away from the side...

no. 2 approach

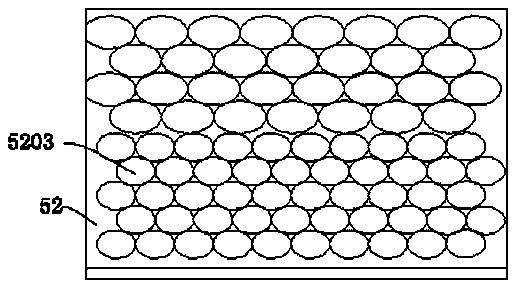

[0021] Second embodiment: see Figure 1-3 , a typhoon-resistant structure of a wind power generation unit, comprising a receiving plate 1, the bottom of the receiving plate 1 is fixedly connected with a seabed anchor 2, and a tower 3 is arranged at the midpoint of the top of the receiving plate 1, and the tower The top of the tube 3 is provided with blades 4, and the top of the receiving plate 1 is fixedly connected with main supporting columns 5, the number of the main supporting columns 5 is four and they are respectively fixedly connected at the four corners of the receiving plate 1 top, the The side of the main support column 5 close to the tower tube 3 is fixedly connected with the tower tube 3, and the two adjacent main support columns 5 are fixedly connected by a connecting block 6, and the connecting block 6 is far away from the midpoint of the side of the tower tube 3 There is a groove 7 at the place, and the inside of the groove 7 is provided with a pressing block 8....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com