Prefabricated building formwork system and wall modules

A construction formwork and assembly technology, which is applied in the direction of construction, building structure, formwork/formwork/work frame, etc., can solve the problems of high construction energy consumption, hidden quality hidden dangers, and heavy overall weight, so as to improve on-site construction progress, reduce the overall construction cost, and save the effect of steel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

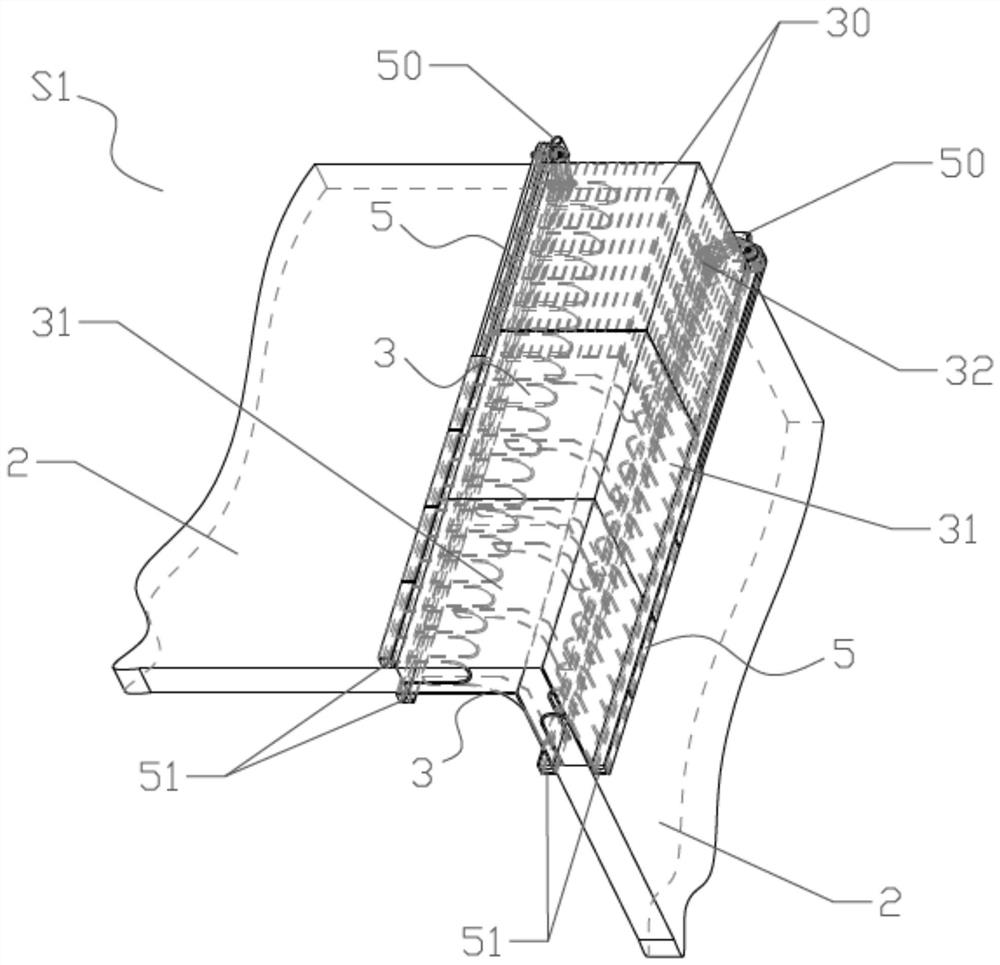

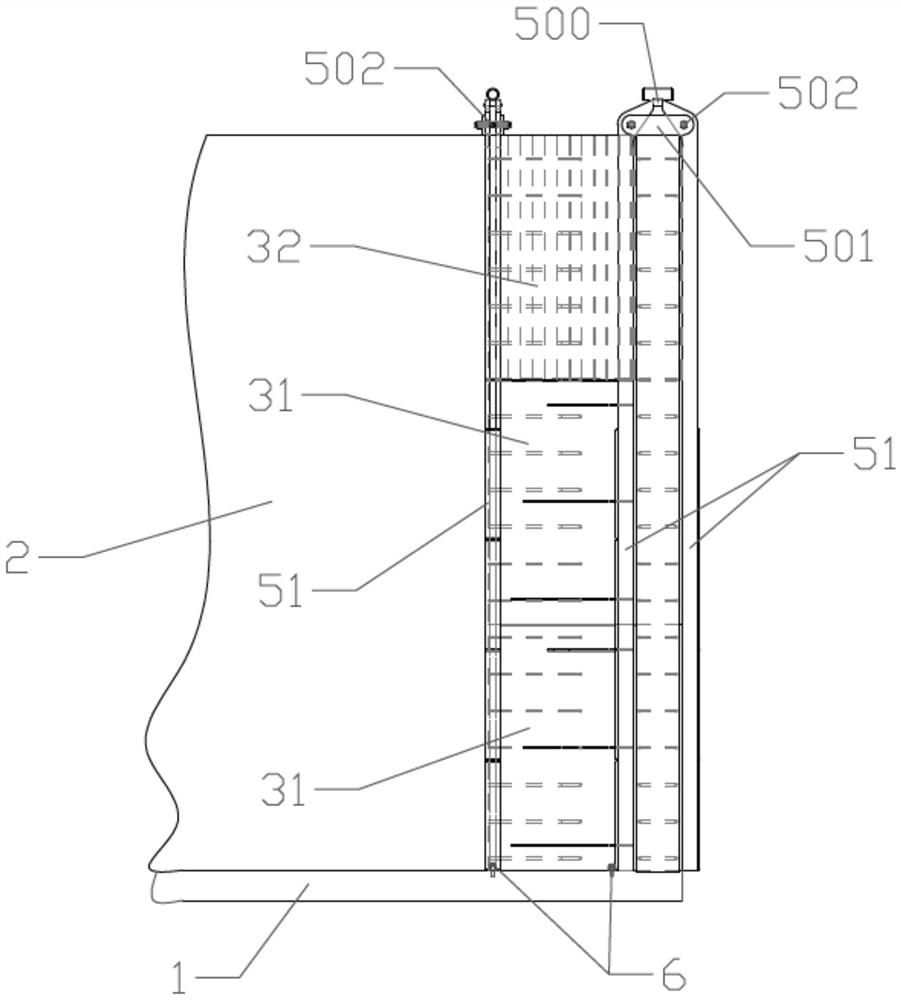

[0034] see Figure 1~5 , the prefabricated building formwork system of the present invention includes a horizontally arranged prefabricated floor slab 1, at least two prefabricated wall panels 2 erected on the prefabricated floor slab 1 and a composite formwork 3, and the prefabricated floor slabs 1 are connected by a composite formwork 3, so A cavity for pouring concrete is formed between the prefabricated wallboard 2, the composite formwork 3 and the prefabricated floor 1; the composite formwork 3 is composed of at least one ribbed steel formwork 31 and at least one polymer plastic formwork 32 stacked, and The ribbed steel formwork is located below the polymer plastic formwork.

[0035] The prefabricated building formwork system is right-angled, and the right-angled prefabricated building formwork system S1 includes two prefabricated wall panels 2 and two composite formworks 3, and the two prefabricated wall panels 2 are arranged at right angles on the horizontal plane, resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com