Dual metallic copper/cobalt metal-organic framework material as well as preparation method and application thereof

An organic framework and bimetallic technology, applied in the field of bimetallic copper/cobalt-organic framework material and its preparation, can solve the problems of secondary pollution, increase of processing cost, cobalt ions cannot be recycled and utilized in the environment, and achieve convenient operation and reaction The effect of short time and easy recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

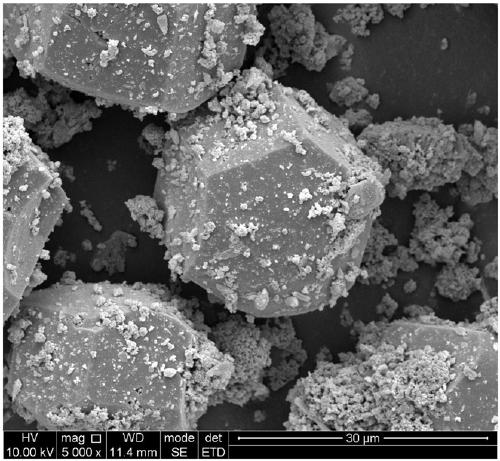

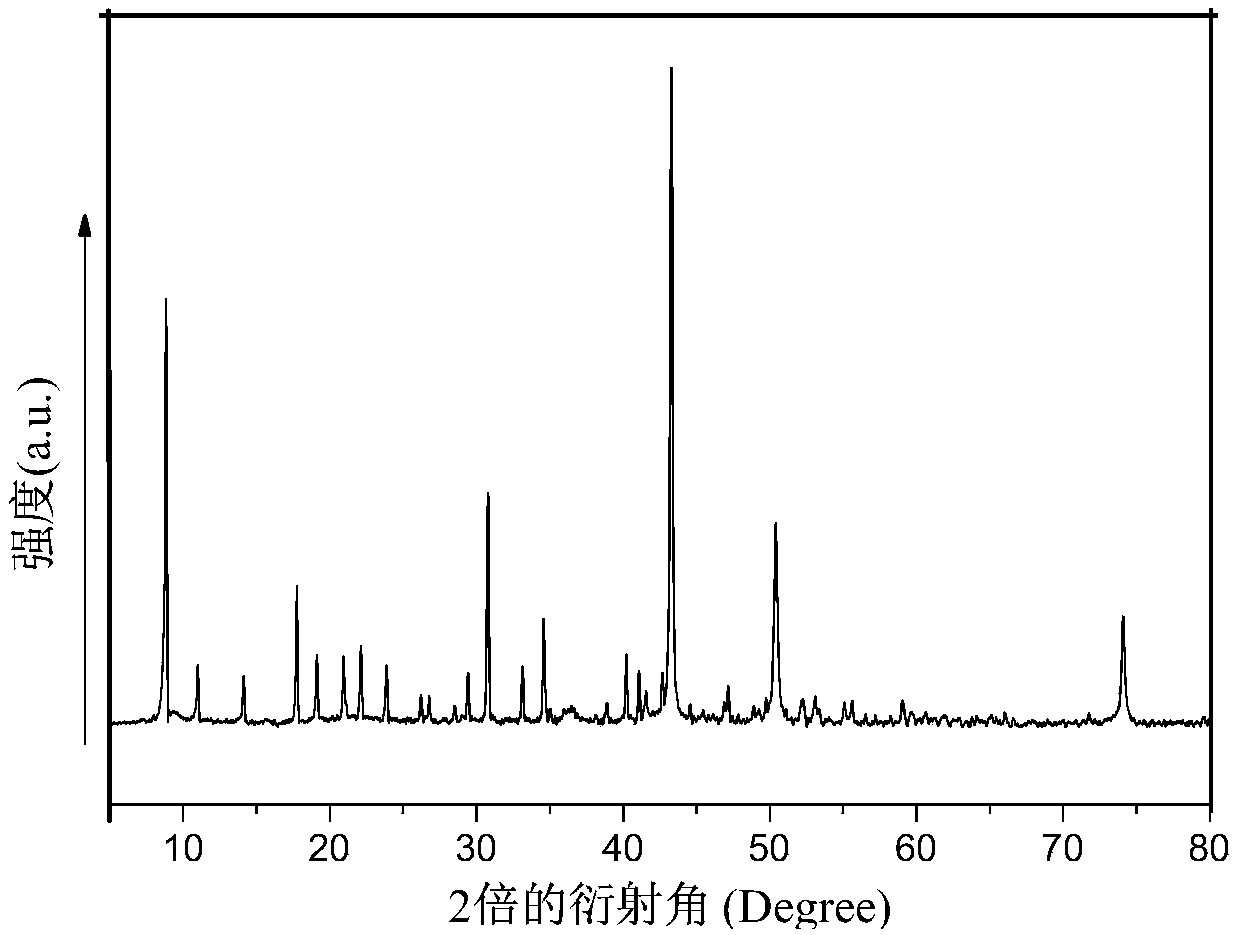

[0035] Preparation of Bimetallic Copper / Cobalt-Organic Frameworks

[0036] (1) Preparation of precursor solution: 1.946g (6mM) Co(NO 3 ) 2 ·6H 2 O, 1.125g (6mM) Cu(NO 3 ) 2 and 1.994g (12mM) of terephthalic acid (BDC) were dissolved in 60mL of N,N-dimethylformamide (DMF), then 0.8mL of hydrofluoric acid (HF) was added, and the above mixture was stirred until completely Dissolving to obtain a precursor solution;

[0037] (2) Preparation of bimetallic copper / cobalt-organic framework material: the precursor solution prepared in step (1) was transferred to a 100mL polytetrafluoroethylene-lined autoclave, and the reactor was placed in a programmed oven. Solvent thermal reaction at 150°C for 72 hours; cool down, cool down to room temperature naturally, and then wash with absolute ethanol, N,N-dimethylformamide (DMF) and deionized water repeatedly after vacuum pump filtration to obtain a brown precipitate; put the precipitate into Dry in a vacuum oven at 100° C. for 12 hours to...

Embodiment 2

[0042] (1) Preparation of precursor solution: 1.946g (6mM) Co(NO 3 ) 2 ·6H 2 O, 1.125g (6mM) Cu(NO 3 ) 2 and 1.329g (8mM) terephthalic acid (BDC) were dissolved in 60mL of N,N-dimethylformamide (DMF), then 0.8mL hydrofluoric acid (HF) was added, and the above mixture was stirred until completely Dissolving to obtain a precursor solution;

[0043] (2) Preparation of bimetallic copper / cobalt-organic framework material: the precursor solution prepared in step (1) was transferred to a 100mL polytetrafluoroethylene-lined autoclave, and the reactor was placed in a programmed oven. Solvent thermal reaction at 150°C for 72 hours; cool down, cool down to room temperature naturally, and then wash with absolute ethanol, N,N-dimethylformamide (DMF) and deionized water repeatedly after vacuum pump filtration to obtain a brown precipitate; put the precipitate into Dry in a vacuum oven at 100° C. for 12 hours to obtain a brown solid powder, which is a bimetallic copper / cobalt-organic fr...

Embodiment 3

[0045] (1) Preparation of precursor solution: 2.095g (7.2mM) Co(NO 3 ) 2 ·6H 2 O, 0.90g (4.8mM) Cu(NO 3 ) 2 and 1.994g (12mM) terephthalic acid (BDC) were dissolved in 60mL of N,N-dimethylformamide (DMF), then 0.8mL hydrofluoric acid (HF) was added, and the above mixture was stirred until completely Dissolving to obtain a precursor solution;

[0046] (2) Preparation of bimetallic copper / cobalt-organic framework material: the precursor solution prepared in step (1) was transferred to a 100mL polytetrafluoroethylene-lined autoclave, and the reactor was placed in a programmed oven. Solvent thermal reaction at 150°C for 72 hours; cool down, cool down to room temperature naturally, and then wash with absolute ethanol, N,N-dimethylformamide (DMF) and deionized water repeatedly after vacuum pump filtration to obtain a brown precipitate; put the precipitate into Dry in a vacuum oven at 100° C. for 12 hours to obtain a brown solid powder, which is a bimetallic copper / cobalt-organi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com