A pharmaceutical wastewater treatment device with high efficiency resource recovery and low energy consumption and its operation method

A technology for resource recovery and pharmaceutical wastewater, applied in energy wastewater treatment, natural water treatment, multi-stage water treatment, etc., can solve the problems of poor biogas quality, adding a large amount of carbon sources, poor applicability, etc., and achieve improved shock load resistance , Improve the ability of acid production, increase the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1: This example uses a set of small-scale test equipment. The pharmaceutical wastewater to be treated is taken from the effluent of a fermentation pharmaceutical enterprise workshop. The wastewater is orange and has a variety of organic substances. The influent volume is 30L / d, and the influent COD is 14500-17000mg / L , pH6.2-6.9, turbidity 179-226mg / L.

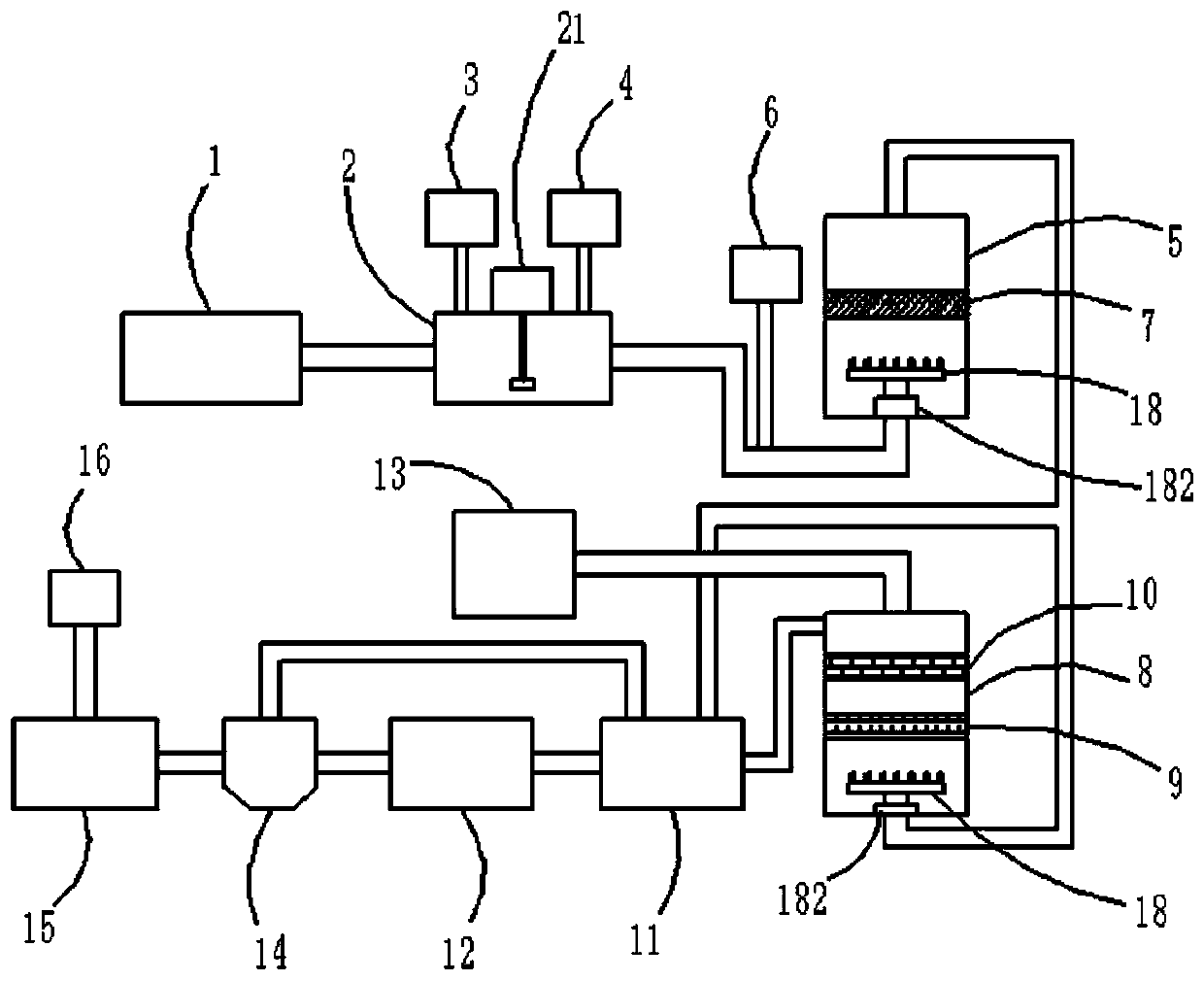

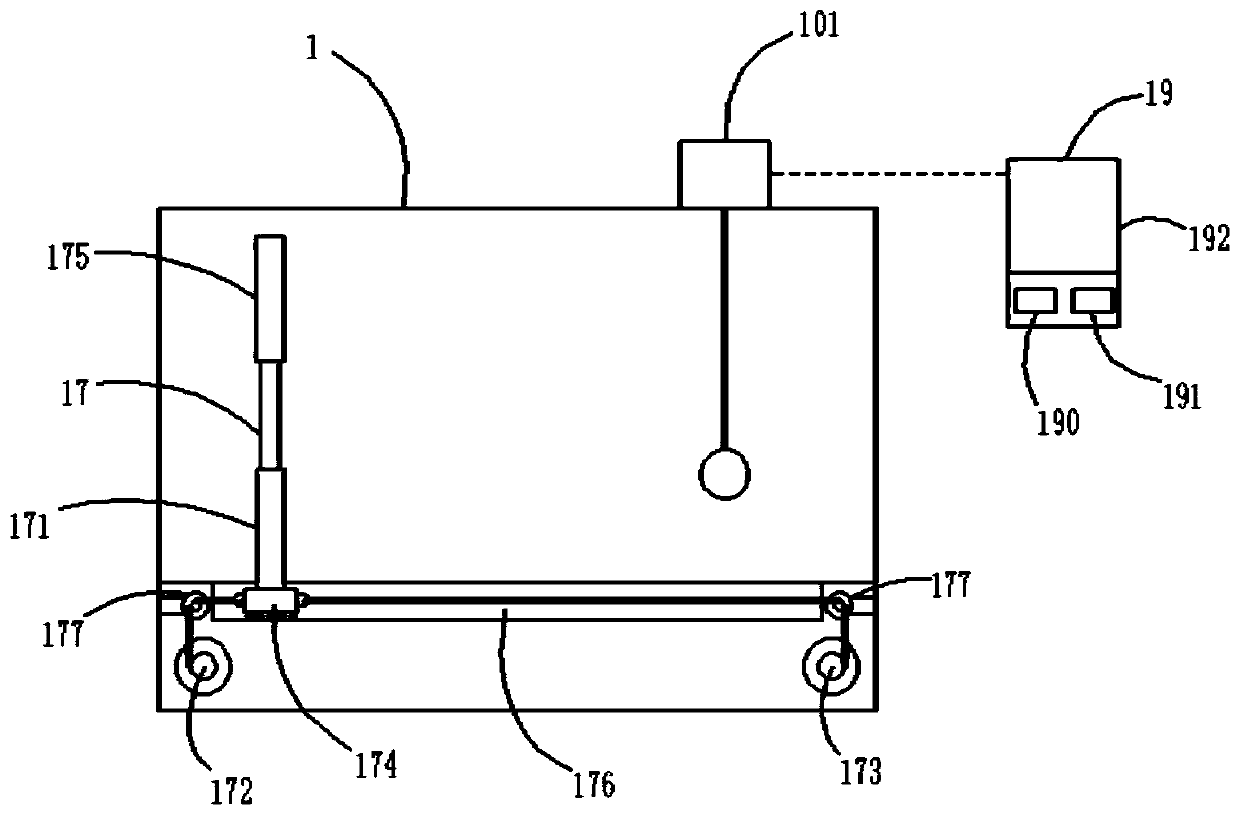

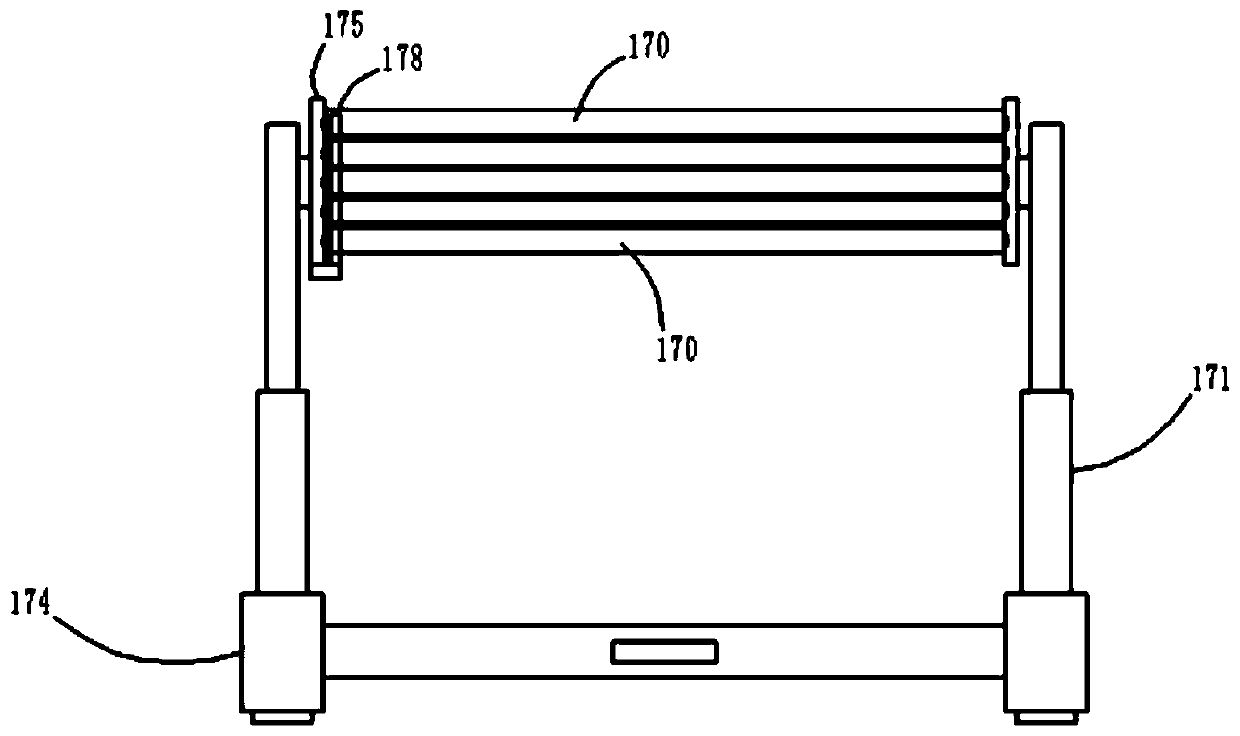

[0032] The structure of the small test device is as follows: figure 1 As shown, it is a pharmaceutical wastewater treatment device with high-efficiency resource recovery and low energy consumption, mainly including air flotation tank 1, regulating tank 2, acid dosing tank 3, alkali dosing tank 4, enhanced hydrolysis acidification tank 5, micron calcium silicate Dosing tank 6, high-efficiency methane production tank 8, anoxic tank 11, aerobic tank 12, biogas collection and treatment device 13, secondary sedimentation tank 14, coagulation sedimentation tank 15, PAC dosing tank 16, control device 19 and power suppl...

Embodiment 2

[0041] Example 2: The difference from Example 1 is that the pharmaceutical wastewater to be treated is taken from the mixed effluent of a certain pharmaceutical company workshop, the wastewater is orange-red, and there are many kinds of organic matter. .7-7.2, turbidity 148-169mg / L.

[0042] The structure of the small test device is as follows:figure 1 As shown, it is a pharmaceutical wastewater treatment device with high-efficiency resource recovery and low energy consumption, mainly including air flotation tank 1, regulating tank 2, acid dosing tank 3, alkali dosing tank 4, enhanced hydrolysis acidification tank 5, micron calcium silicate Dosing tank 6, high-efficiency methane production tank 8, anoxic tank 11, aerobic tank 12, biogas collection and treatment device 13, secondary sedimentation tank 14, coagulation sedimentation tank 15, PAC dosing tank 16, control device 19 and power supply; Air flotation tank 1, regulating tank 2, enhanced hydrolysis acidification tank 5, h...

Embodiment 3

[0051] Example 3: This example adopts a pilot test device. The pharmaceutical wastewater to be treated is the fermentation wastewater of an anticancer drug. The influent COD18500-21900mg / L, pH6.4-6.7, SS764-1128mg / L, and the influent water volume is 4m3 / d .

[0052] The structure of the pilot test device is as follows: figure 1 As shown, it is a pharmaceutical wastewater treatment device with high-efficiency resource recovery and low energy consumption, mainly including air flotation tank 1, regulating tank 2, acid dosing tank 3, alkali dosing tank 4, enhanced hydrolysis acidification tank 5, micron calcium silicate Dosing tank 6, high-efficiency methane production tank 8, anoxic tank 11, aerobic tank 12, biogas collection and treatment device 13, secondary sedimentation tank 14, coagulation sedimentation tank 15, PAC dosing tank 16, control device 19 and power supply; Air flotation tank 1, regulating tank 2, enhanced hydrolysis acidification tank 5, high-efficiency methane p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com