A high temperature phase tio 2 (b) Preparation method of the material

A high-temperature, pure-phase technology, applied in the field of photocatalytic degradation of pollutants, can solve problems such as limited applications, and achieve the effects of simple preparation methods, low raw material prices, and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

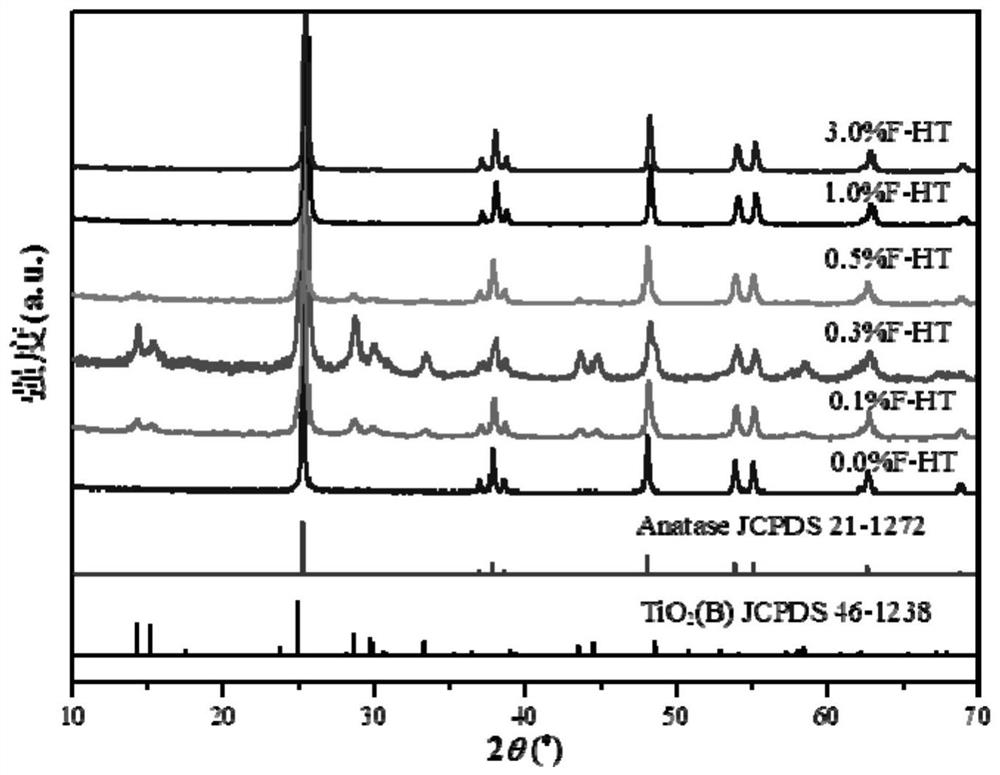

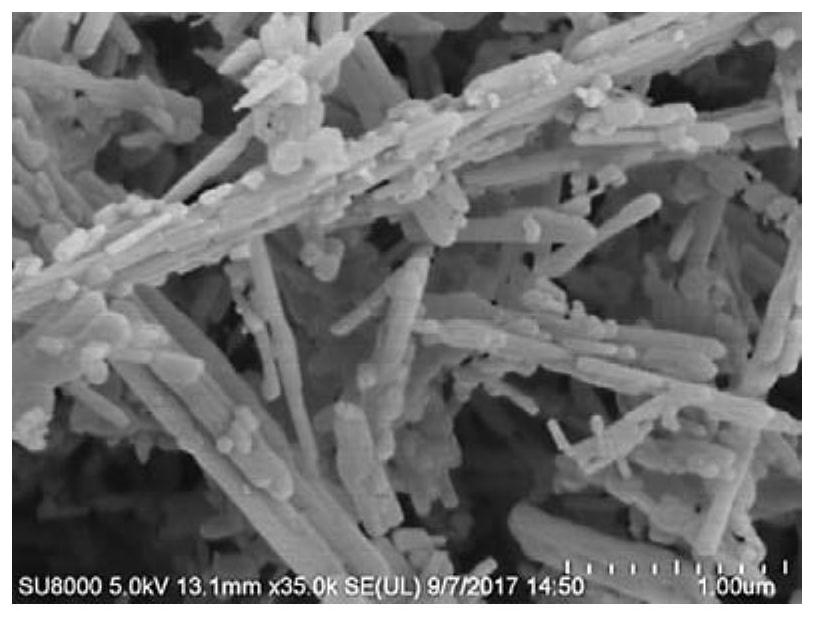

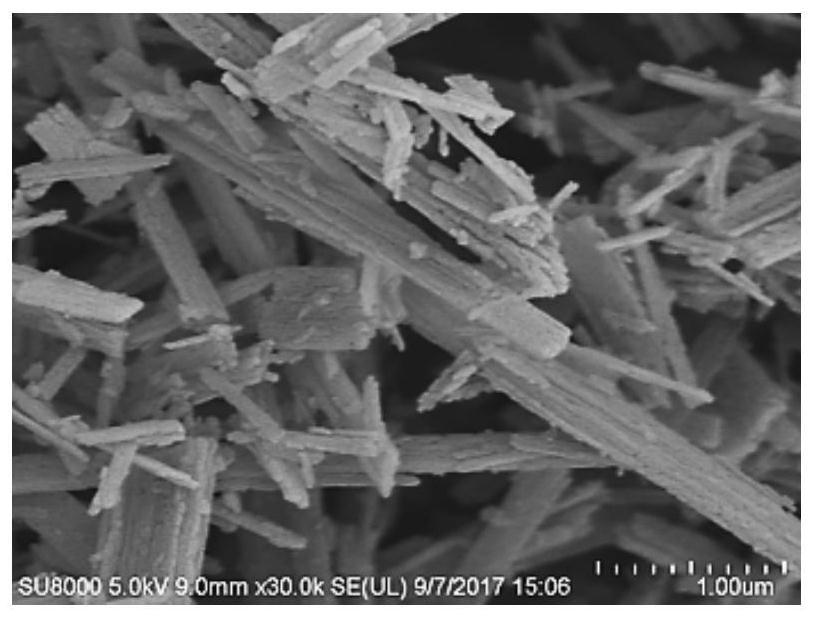

Embodiment 1

[0023] Add 6 mL of titanium tetra-n-butoxide and 3 mL of acetic acid into 20 mL of ethylene glycol, stir evenly for 15 min, then add 30 mL of 15 mol / L NaOH aqueous solution, and continue stirring for 10 min. The resulting mixture was transferred to a 100 mL hydrothermal reactor, placed in an oven at 180 °C for 12 h, cooled to room temperature naturally, taken out, filtered with suction and washed with deionized water and ethanol until neutral, and the obtained filtrate Stir in 300 mL of 0.1 mol / L HCl aqueous solution for 12 h, filter with suction, wash with deionized water and ethanol until neutral, and dry at 80 °C for 12 h to obtain TiO 2 (B) Precursor H 2 Ti 4 o 9 . 0.3 g TiO 2 (B) Precursor H 2 Ti 4 o 9 Disperse with 0.01 mL of hydrofluoric acid (the mass fraction of hydrogen fluoride is 49%) in 10 mL of deionized water, place in a 20 mL small crucible and stir evenly for 4 h to form a uniformly dispersed suspension. The mass of hydrogen fluoride in the obtained sus...

Embodiment 2

[0025] In this example, the amount of hydrofluoric acid used is 0.03 mL, and the other steps are the same as in Example 1 to obtain the high-temperature phase TiO 2 (B) Material, recorded as 0.3% F-HT.

Embodiment 3

[0027] In this example, the amount of hydrofluoric acid was 0.05 mL, and the other steps were the same as in Example 1 to obtain the high-temperature phase TiO 2 (B) Material, recorded as 0.5% F-HT.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com