A modified cobalt-free lithium-rich cathode material, its preparation method and application

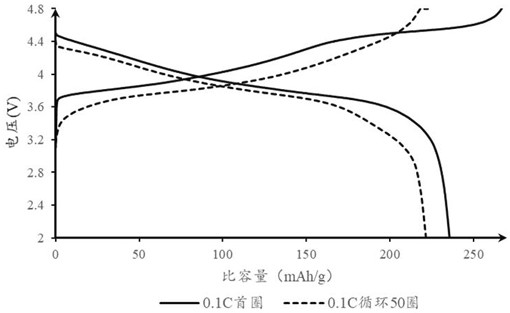

A lithium-rich positive electrode material and positive electrode technology, applied in the direction of positive electrodes, active material electrodes, chemical instruments and methods, etc., can solve the problems of low utilization rate, cycle voltage decay, and large influence of natural conditions, so as to improve the first effect , reduce voltage attenuation, and slow down the effect of phase change process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] This embodiment provides a method for preparing a modified cobalt-free lithium-rich cathode material, and the preparation method specifically includes the following steps:

[0046] (1) Take 100g of cobalt-free hydroxide precursor Ni 0.4 Mn 0.6 (OH) 2 Stir and mix with 62g LiOH evenly, put it into a box-type atmosphere furnace, pass in air and calcinate at 300 ℃ for 6 hours to obtain a pre-fired material;

[0047] (2) Add 1.55 g of sodium dihydrogen phosphate to all the cobalt-free and lithium-rich pre-sintered materials, mix them evenly, put them into a box-type atmosphere furnace, and calcinate at 800° C. for 10 hours to obtain sodium-doped cobalt-free lithium-rich materials;

[0048] (3) Add 5g of sodium-doped cobalt-free and lithium-rich material into 100ml of absolute ethanol, add 1.5mol / L ammonia water dropwise to the absolute ethanol, after the dropwise addition is completed, put it in a 25°C water bath and stir for 6h; After the stirring was completed, 10 mg o...

Embodiment 2

[0052] This embodiment provides a method for preparing a modified cobalt-free lithium-rich cathode material, and the preparation method specifically includes the following steps:

[0053] (1) Take 100g of cobalt-free hydroxide precursor Ni 0.4 Mn 0.6 (OH) 2 Stir and mix with 62g LiOH evenly, put it into a box-type atmosphere furnace, pass in air and calcinate at 300 ℃ for 6 hours to obtain a pre-fired material;

[0054] (2) Add 1.02 g of sodium titanate to all the cobalt-free and lithium-rich pre-sintered materials, mix them evenly, put them into a box-type atmosphere furnace, and calcinate at 800° C. for 10 hours to obtain a sodium-doped cobalt-free lithium-rich material;

[0055] (3) Take 5g of sodium-doped cobalt-free lithium-rich material and add it to 100ml of absolute ethanol, add 1 mol / L ammonia water dropwise to the absolute ethanol, after the dropwise addition is completed, put it in a 30°C water bath and stir for 6h; stir; After completion, add 10 mg of tetrabutyl...

Embodiment 3

[0058] This embodiment provides a method for preparing a modified cobalt-free lithium-rich cathode material, and the preparation method specifically includes the following steps:

[0059] (1) Take 100g of cobalt-free hydroxide precursor Ni 0.4 Mn 0.6 (OH) 2 Stir and mix with 62g LiOH evenly, put it into a box-type atmosphere furnace, pass in air and calcinate at 300 ℃ for 6 hours to obtain a pre-fired material;

[0060] (2) Add 1.55 g of sodium alginate to all the cobalt-free and lithium-rich pre-burned materials, mix them evenly, put them into a box-type atmosphere furnace, and calcinate at 800° C. for 10 hours to obtain a sodium-doped cobalt-free lithium-rich material;

[0061] (3) Add 5g of sodium-doped cobalt-free and lithium-rich material into 100ml of absolute ethanol, add 1.2mol / L ammonia water dropwise to the absolute ethanol, and after the dropwise addition is completed, put it into a 40°C water bath and stir for 6h; After the stirring was completed, 9 mg of tetrab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com