Scanning method for restraining bending deformation of laser-welded thin plate

A technology of laser welding and bending deformation, used in laser welding equipment, welding equipment, manufacturing tools, etc., to improve welding efficiency and quality, reduce temperature gradients, and be easy to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

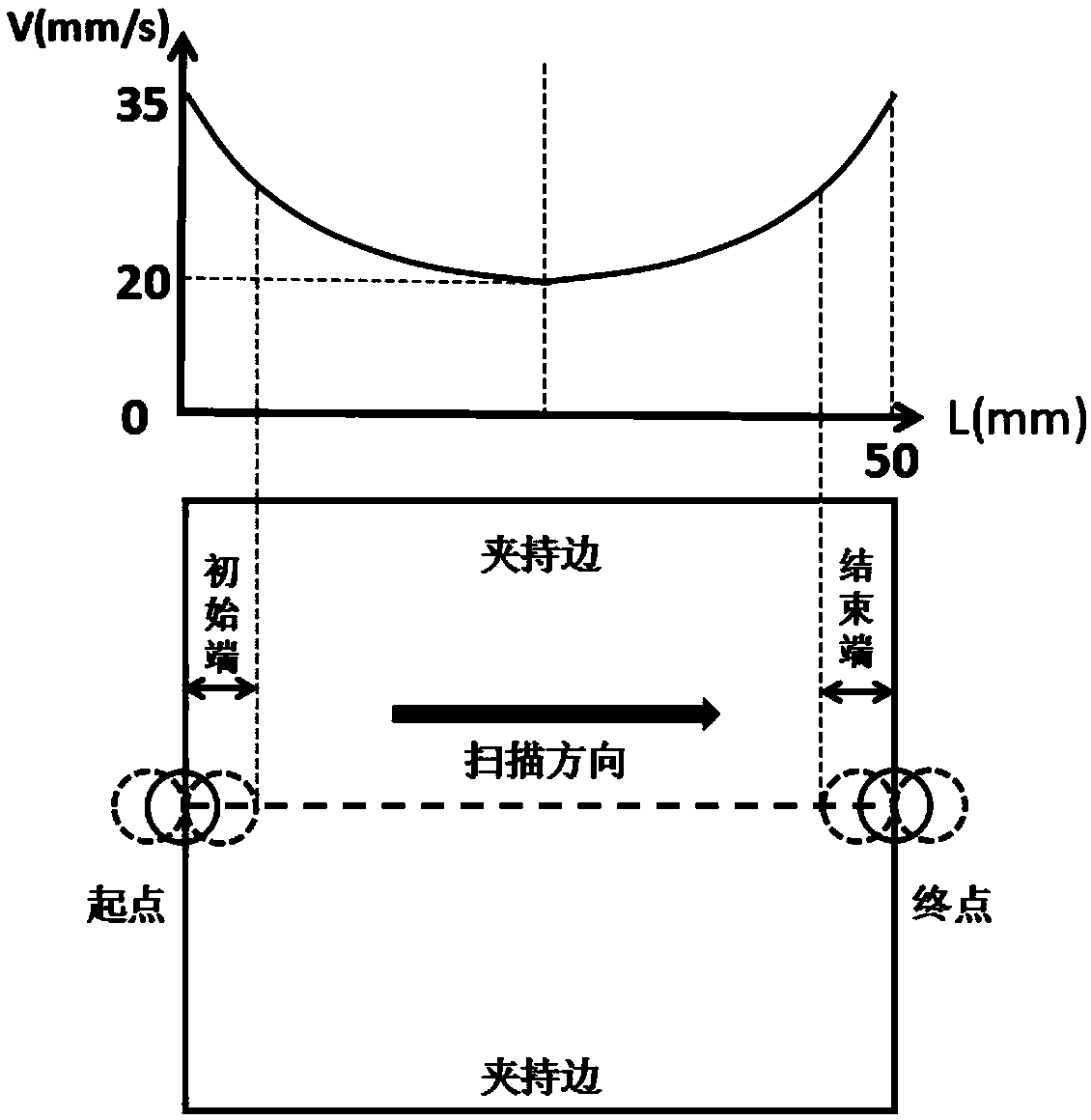

[0030] On the basis of clamping and fixing the free edges on both sides of the thin plate, by adopting the "symmetrical parabola" type variable speed scanning method, on the premise of ensuring reasonable laser heat input, to reduce the heat input caused by excessive heat input at the first and last ends of the thin plate welding The pit collapses, while reducing the undesired bending deformation during the welding process, the steps are:

[0031] Step S1: Weld a 1.5mm thick Q235 thin plate sample, pre-treat the surface of the sample by grinding, polishing, cleaning and drying, and place the pre-treated sample in a thermostat at 200°C for 1 hour for preheating ;

[0032] Step S2: Place the preheated Q235 thin plate sample with the surface to be processed facing up, fix it on the welding table with the existing special welding fixture, and restrict the movement of the workpiece by pressing the free edges on both sides. The free edge compression on both sides refers to the use ...

Embodiment 2

[0037] On the basis of clamping and fixing the free edges on both sides of the thin plate, by adopting the "symmetrical parabola" type variable speed scanning method, on the premise of ensuring reasonable laser heat input, to reduce the heat input caused by excessive heat input at the first and last ends of the thin plate welding The pit collapses, while reducing the undesired bending deformation during the welding process, the steps are:

[0038] Step S1: Weld a 0.5mm thick Q235 thin plate sample, pre-treat the surface of the sample by grinding, polishing, cleaning and drying, and place the pre-treated sample in a thermostat at 200°C for 1 hour for preheating ;

[0039] Step S2: Fix the preheated Q235 thin plate sample on the welding table with the surface to be processed facing upward, and use the free edge compression method on both sides to limit the movement of the workpiece;

[0040] Step S3: Set laser welding process parameters: laser power is 2300W, defocus amount is ...

Embodiment 3

[0044] On the basis of clamping and fixing the free edges on both sides of the thin plate, by adopting the "symmetrical parabola" type variable speed scanning method, on the premise of ensuring reasonable laser heat input, to reduce the heat input caused by excessive heat input at the first and last ends of the thin plate welding The pit collapses, while reducing the undesired bending deformation during the welding process, the steps are:

[0045] Step S1: Weld a 2mm thick Q235 thin plate sample, grind, polish, clean and dry the surface of the sample, and place the pretreated sample in a thermostat at 200°C for 1 hour for preheating;

[0046] Step S2: Fix the preheated Q235 thin plate sample on the welding table with the surface to be processed facing upward, and use the free edge compression method on both sides to limit the movement of the workpiece;

[0047] Step S3: Set the laser welding process parameters: the laser power is 2500W, the defocus is 0mm, the spot diameter is 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Defocus amount | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com