Flow-control and variable-temperature spray drying system

A drying system, spray drying tower technology, applied in spray evaporation, evaporator accessories and other directions, can solve the problems of increasing the difficulty of transportation and installation, increasing production costs, economic losses, etc., to ensure no cross-contamination, improve product yield, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

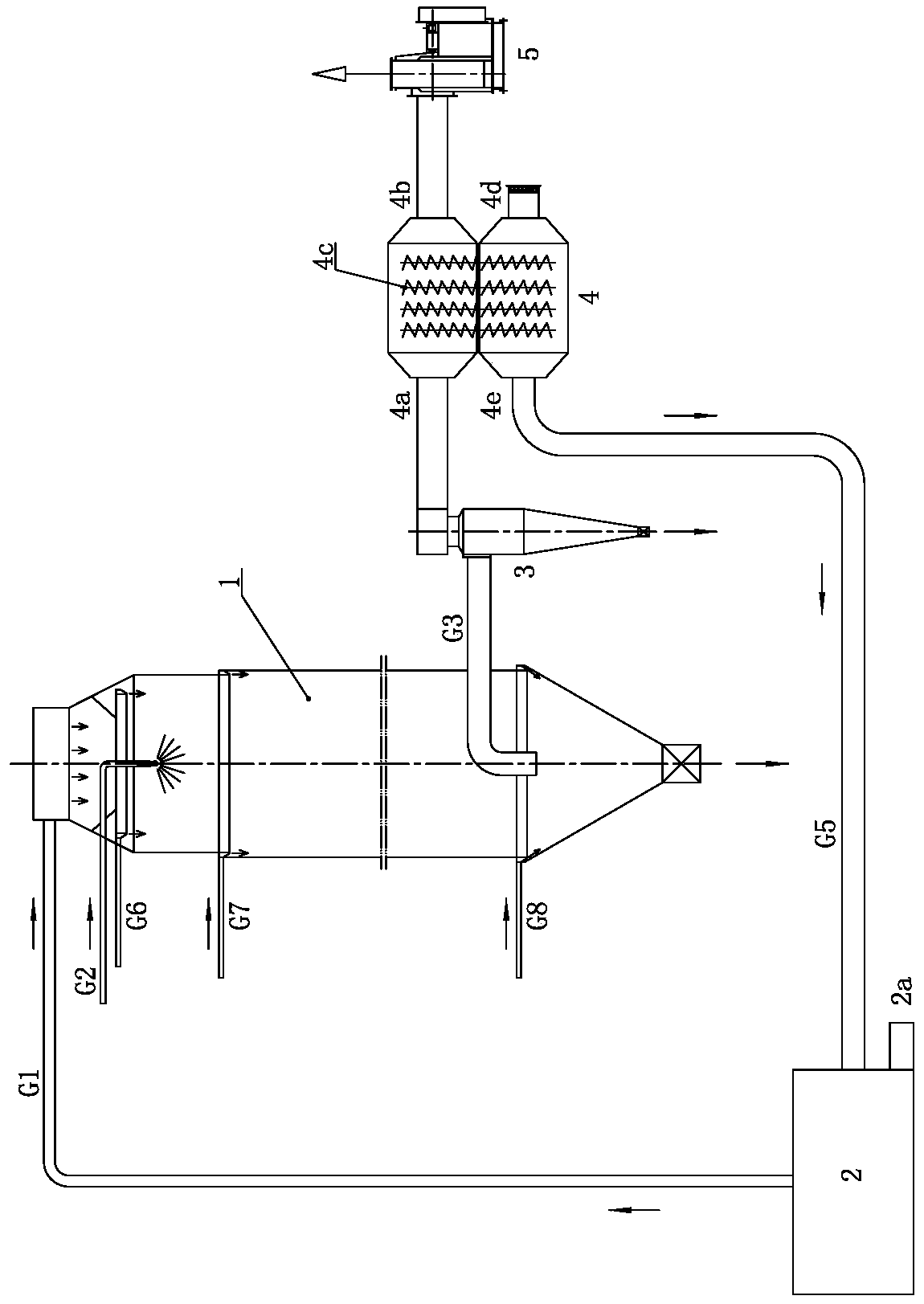

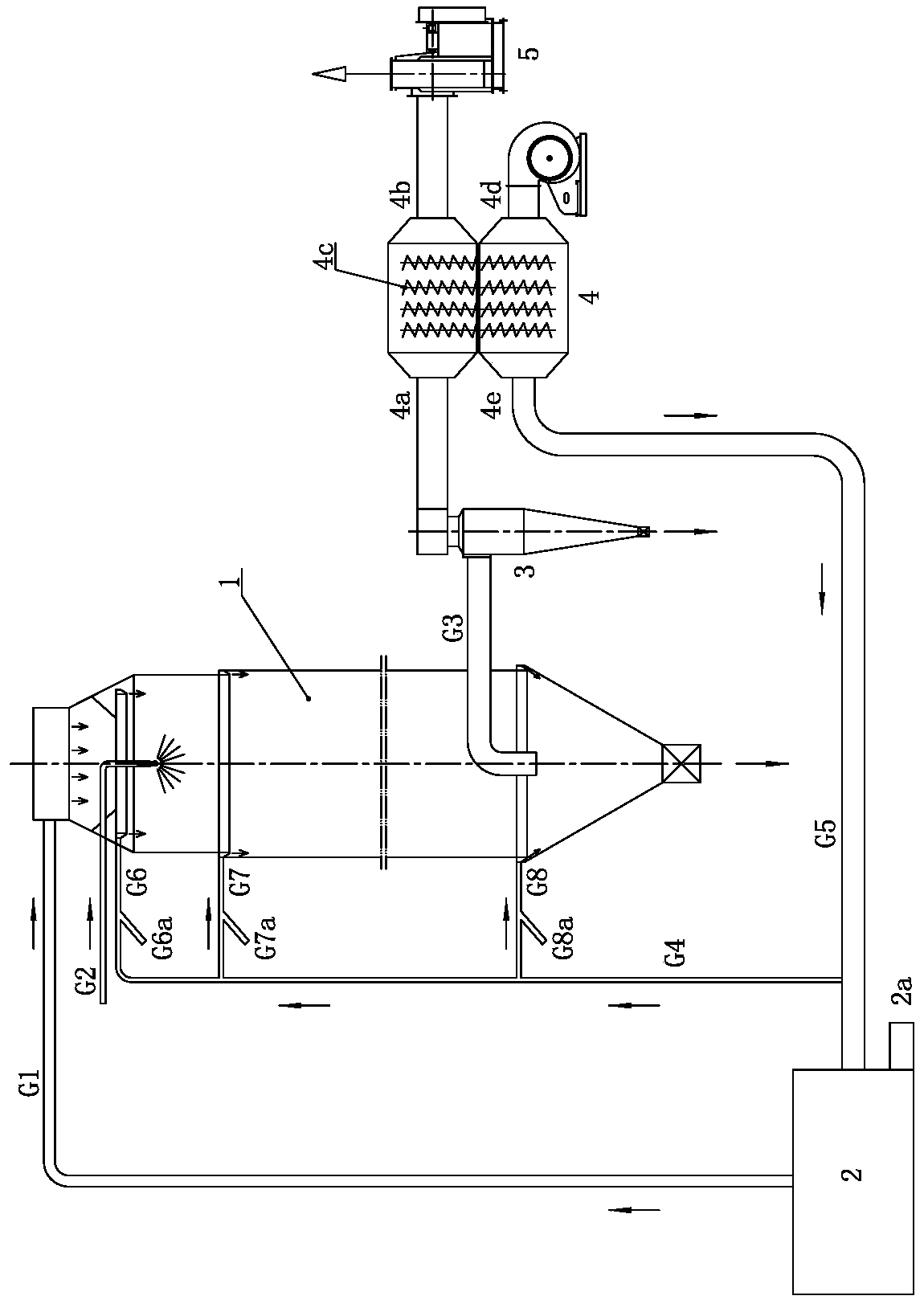

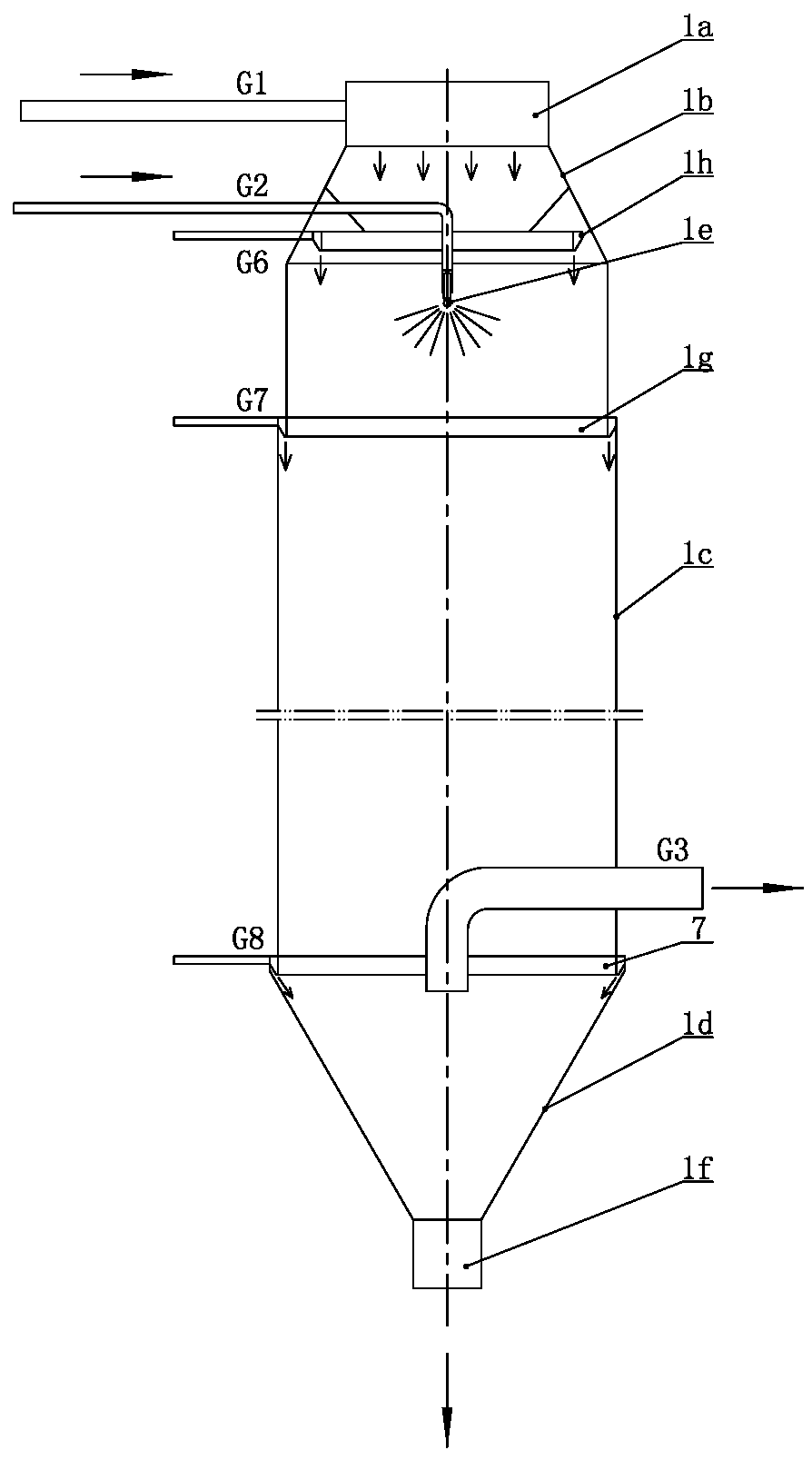

[0025] like Figure 1 to Figure 6 As shown, the spray drying system with flow control and variable temperature of the present invention includes a heating device 2, a spray drying tower 1 and an induced draft fan 5, and the spray drying tower 1 includes an air equalizing section 1a connected in sequence from top to bottom and coaxial, and a cone on the tower. 1b, cylinder 1c and lower cone 1d, the side wall of the uniform air section 1a is connected to the tower body hot air main pipe G1, the side wall of the tower upper cone 1b is connected to the feed liquid pipe G2, and the inner end of the feed liquid pipe G2 is connected to the feed liquid The atomization device 1e is connected, and the material liquid atomization device 1e is located on the axis of the cylinder 1c. The lower end of the cylinder 1c is connected to the tower body exhaust pipe G3, and the inner end of the tower body exhaust pipe G3 can extend to the axis of the cylinder body And the port turns downward, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com