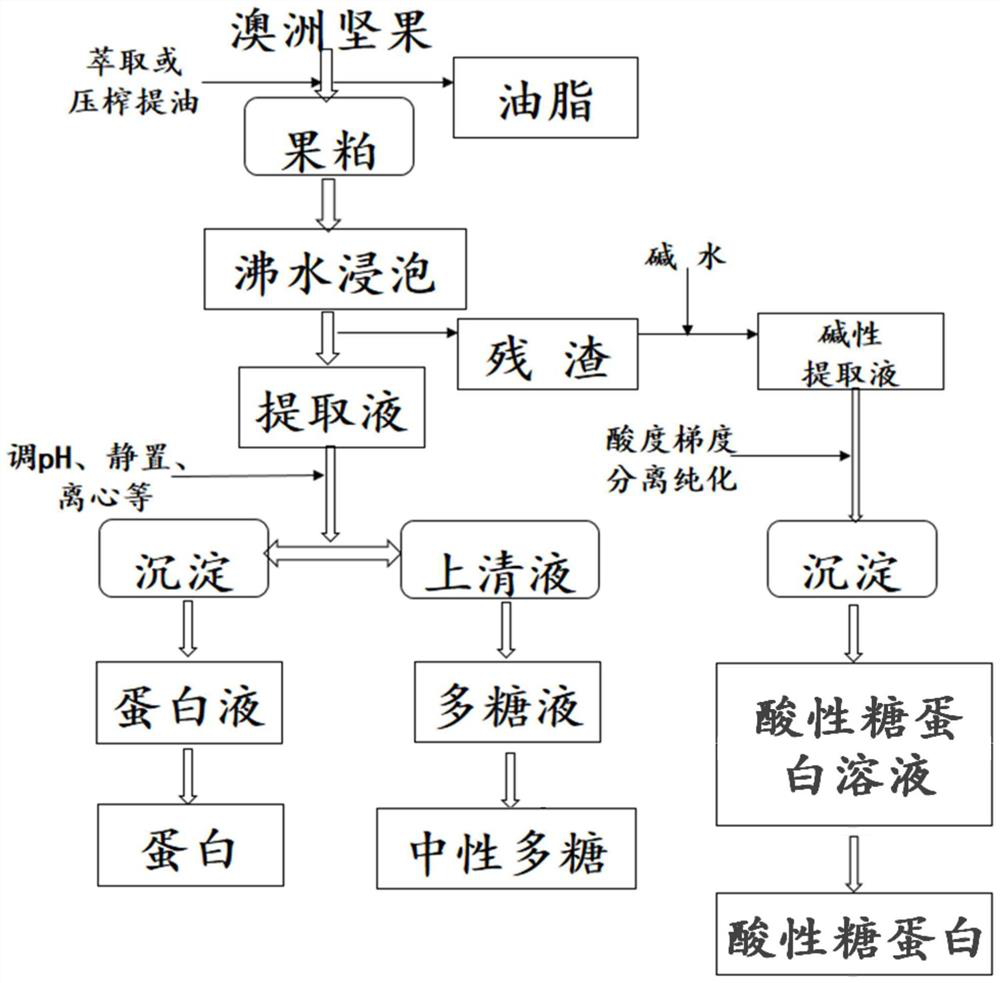

A kind of acidic macadamia nut glycoprotein and its production method

A technology of acidic glycoprotein and production method, which is applied in the field of acidic macadamia glycoprotein and its production, can solve the problems of unmentioned residue application, achieve good application prospects, high purity, and improve the effect of resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Take 250Kg of shelled macadamia nuts without insects and rot, and about 100Kg of dried and shelled nuts, and about 25Kg of oily meal after oil degreasing in a press; air-dry the oily meal and crush it through a 40-mesh sieve , and then soaked in about 200Kg water for about 1 hour, quickly heated to boiling, and took out the extract after maintaining for 1 hour; the residue was extracted twice according to this method, after collecting the above three extracts, adjust the pH to 4.3, and stand still to obtain the precipitated protein. After centrifugation, precipitation collection and drying, the protein product is obtained. The supernatant after protein precipitation is adjusted to neutral pH, then concentrated by vacuum evaporation at 60°C to a water content below 70%, and then spray-dried or freeze-dried to obtain neutral polysaccharides.

[0051] Add about 8 times (w / v) soda aqueous solution with pH 13 to the remaining residue of the above extraction, heat to boiling ...

Embodiment 2

[0053] Take about 25Kg of macadamia nut oil meal; air-dry the oil meal and crush it through an 80-mesh sieve, let it stand and soak for 1 hour, then heat it to boiling with about 750Kg of water, keep it for 10 minutes, take it out after cooling, and separate the extract; repeat the method for the residue Extract twice, collect all the extracts, adjust the pH to 4.5 until turbidity appears, then centrifuge (<4000rpm), collect the precipitate, and dry to obtain the protein product. The supernatant after protein precipitation is adjusted to neutral pH with soda, then concentrated by vacuum evaporation at 60°C to a water content below 70%, and then spray-dried or freeze-dried to obtain neutral polysaccharides.

[0054] Then add about 20 times (w / v) sodium bicarbonate aqueous solution of pH 10 to the residue after the above extraction, heat to boiling and keep warm for 2 hours to obtain an alkaline extract containing glycoprotein; The extraction was repeated twice; the glycoprotein...

Embodiment 3

[0056] Take 25Kg of oil residue from a macadamia nut company in Yunnan, which uses low-temperature supercritical carbon dioxide as a solvent to extract oil. After drying, crush and pass through a 20-mesh sieve, heat it to boiling with about 300Kg of water and keep it for 0.5h. After cooling, take it out and separate it for extraction. solution; the residue was extracted twice according to this method, and after collecting all the extracts, neutral polysaccharides and proteins were obtained according to the method of Example 1. Then add about 20 times (w / v) sodium bicarbonate aqueous solution of pH 8 to the residue, heat to boiling and keep warm for 1.5h to obtain an alkaline extract containing glycoprotein; then repeat the extraction of the residue 2 times according to the above method; The glycoprotein extracts were collected three times, and after the residue was removed by centrifugation, the acid glycoprotein was obtained according to the method described in Example 1, with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com