Acidic Macadamia nut glycoprotein and production method thereof

A technology of acid glycoprotein and production method, applied in the field of acid macadamia nut glycoprotein and production thereof, can solve problems such as the application of residues not mentioned, and achieve the effects of good application prospect, simple production process, and no waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

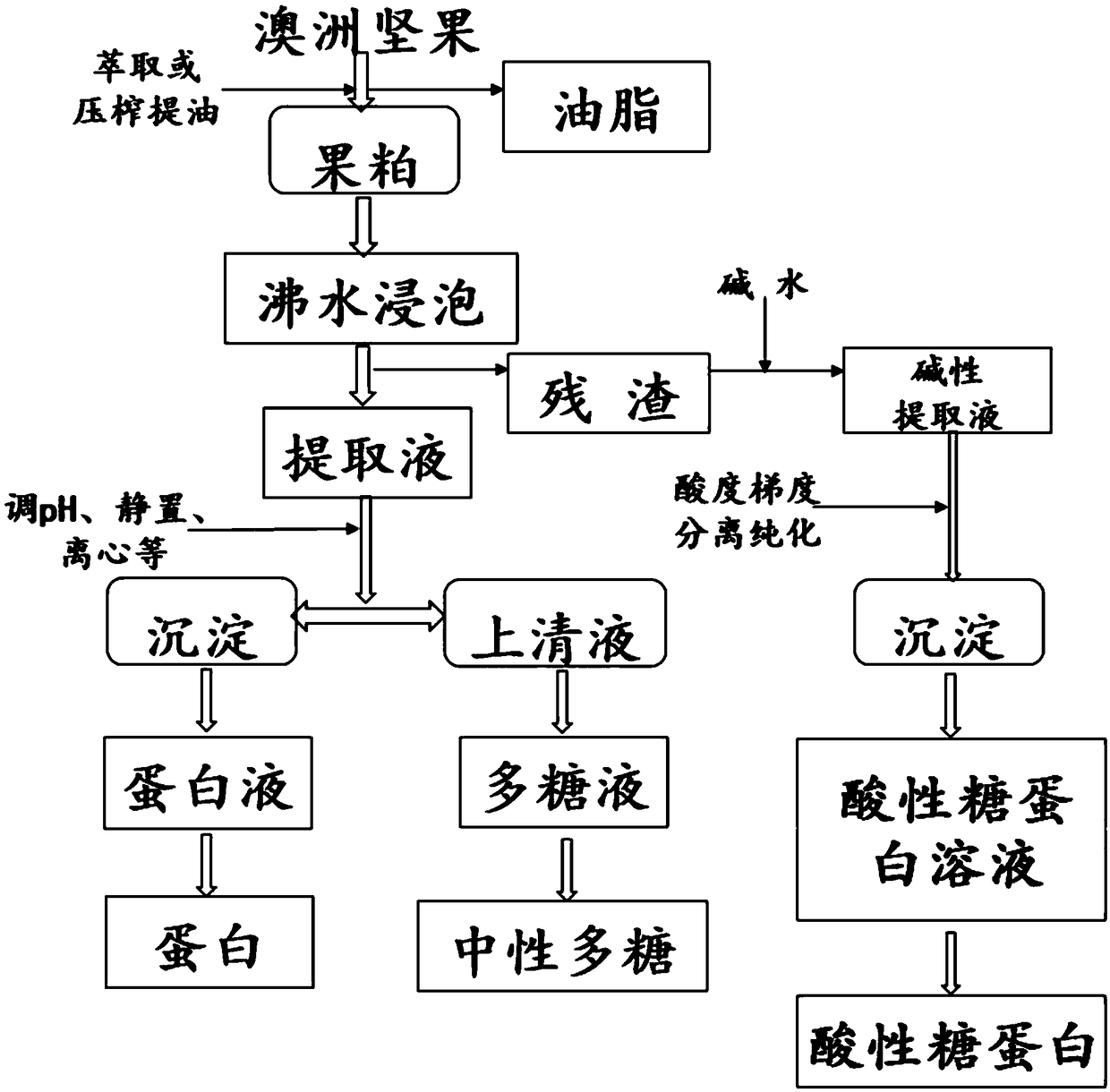

Method used

Image

Examples

Embodiment 1

[0050] Take 250Kg of macadamia nuts without insects and rot in the shell. After drying and dehulling, the kernels are about 100Kg. After the oil is defatted by a press, about 25Kg of oil meal is obtained; the oil meal is air-dried and crushed through a 40-mesh sieve , Then soak in about 200Kg of water for about 1 hour, quickly heat to boiling, and then take out the extract after maintaining for 1 hour; the residue is extracted twice according to this method, after collecting the above three extracts, adjust the pH to 4.3, and let it stand to get the precipitated protein. After centrifugation, collection and drying, the protein product is obtained. The supernatant after protein precipitation, after adjusting the pH to neutral, is concentrated by vacuum evaporation at 60°C to a water content of less than 70%, and spray-dried or freeze-dried to obtain neutral polysaccharides.

[0051] Add about 8 times (w / v) pH 13 soda solution to the remaining residue of the above extraction, heat ...

Embodiment 2

[0053] Take about 25Kg of macadamia nut oil meal; dry the oil meal and pulverize it through an 80-mesh sieve, let it stand for 1 hour, and then heat it with about 750Kg of water to boiling for 10 minutes, after cooling, take out and separate the extract; the residue is repeated according to the method Extract twice. After collecting all the extracts, adjust the pH to 4.5 until turbidity appears, and then centrifuge ( <4000rpm), the protein product obtained after collecting the precipitate and drying. After precipitating the protein, the supernatant is adjusted to neutral pH with soda, and then concentrated by vacuum evaporation at 60°C to a water content of less than 70%. After spray dehydration or freeze drying, neutral polysaccharides are obtained.

[0054] Then add about 20 times (w / v) of a pH 10 aqueous sodium bicarbonate solution to the residue after the above extraction, heat it to boiling and keep it for 2 hours to obtain an alkaline extract containing glycoproteins; then a...

Embodiment 3

[0056] Take 25Kg of oil dregs from a macadamia nut company in Yunnan that uses low-temperature supercritical carbon dioxide as a solvent to extract oil. After drying, pulverize through a 20-mesh sieve, and then use about 300Kg of water to heat to boiling for 0.5h. After cooling, take it out to separate and extract. The residue was extracted twice according to this method. After collecting all the extracts, neutral polysaccharides and proteins were obtained according to the method of Example 1. Then add about 20 times (w / v) of the sodium bicarbonate solution of pH 8 to the residue, heat it to boiling and keep it for 1.5 hours to obtain an alkaline extract containing glycoprotein; then repeat the extraction of the residue twice according to the above method; The glycoprotein extract was collected three times, and after centrifugation to remove the residue, acid glycoprotein was obtained according to the method described in Example 1, with a yield of 2.4% (w / w).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular mass | aaaaa | aaaaa |

| Molecular mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com