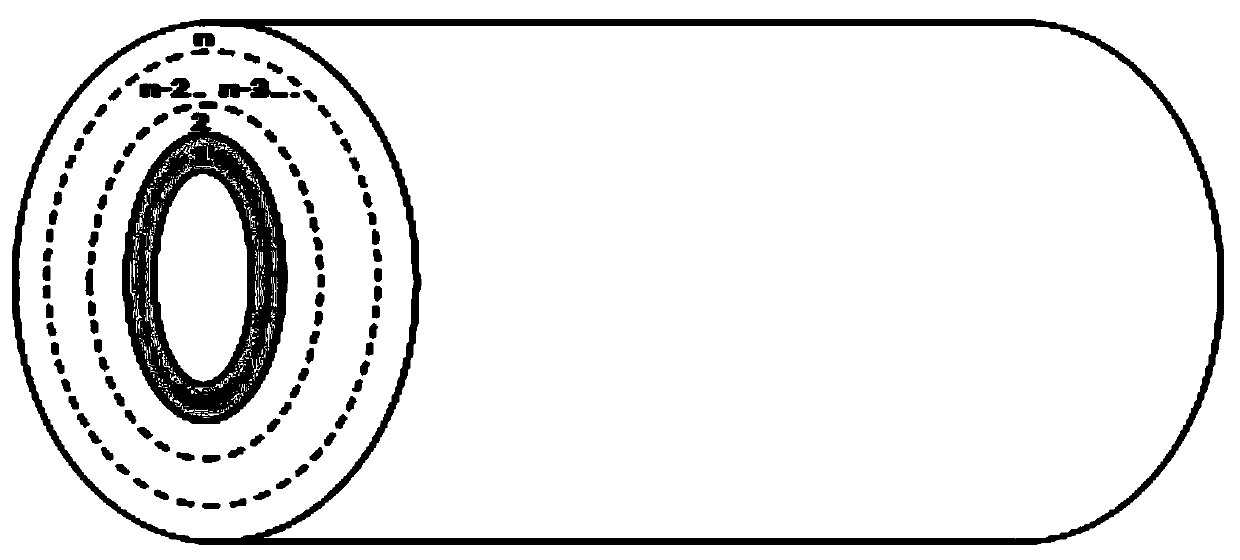

A kind of tubular composite laser medium and its preparation method

A laser medium, tubular technology, applied in the direction of active medium materials, vacuum evaporation plating, coating, etc., to achieve good application prospects, improve single-mode transmission, and overcome the effect of low mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1: Preparation of 2-layer YAG / Yb:YAG tubular composite laser medium by electron beam evaporation deposition method.

[0033]Firstly, a cylindrical rod body of Φ4mm and a length of 200mm is pulled out from a high-quality YAG crystal blank with a diameter of 90mm and a length of 200mm by using a rod pulling machine, and then a YAG hollow rod body with an outer diameter of Φ6.2mm and a length of 200mm is concentrically pulled out to obtain an outer diameter of Φ6. .2mm, inner diameter Φ4mm, and length 200mm YAG tubular substrate; grind the outer diameter of the tubular substrate to 6.05mm, then place it vertically in a high-uniformity annealing furnace, and perform stress annealing at 1000°C; adopt high-precision polishing technology, Polish the tubular cylinder, the outer diameter tolerance of the tubular substrate is ±0.01mm, and the surface roughness is better than 0.1μm; after the tubular cylinder is cleaned, it is placed on the fixture of the electron beam evap...

example 2

[0034] Example 2: Preparation of 3 layers of Al by pulsed laser deposition 2 o 3 / Nd:YAG / YAG tubular composite laser medium.

[0035] Using punching machine in high quality Al 2 o 3 A hole of Φ3 mm and length of 100 mm is drilled on the crystal blank, and then a long strip with a square cross section is cut out along the direction of the hole by a multi-wire cutting machine. The center of the cross section coincides with the center of the hole. The side length of the cross section is 5.2 mm and the length is 100 mm. Grind the outer diameter of the tubular substrate to 5.05mm, then place it vertically in a high-uniformity annealing furnace, and perform stress annealing at 1200°C; use high-precision polishing technology to polish the tubular cylindrical surface, and the tolerance of the outer diameter of the tubular substrate is ±0.01mm, the surface roughness is better than 0.1μm; after cleaning the tubular cylinder, place it on the fixture of the pulse laser deposition equip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com