Pre-fabrication and installation method of phenol-formaldehyde composite air duct based on BIM platform

A composite air duct, prefabricated installation technology, applied in instrumentation, design optimization/simulation, passive house, etc., can solve the problems of environment, human health hazards, thermal insulation sealing of joints, high rework costs, etc., to ensure processing quality, The effect of speeding up the construction progress and avoiding the rework of the air duct

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

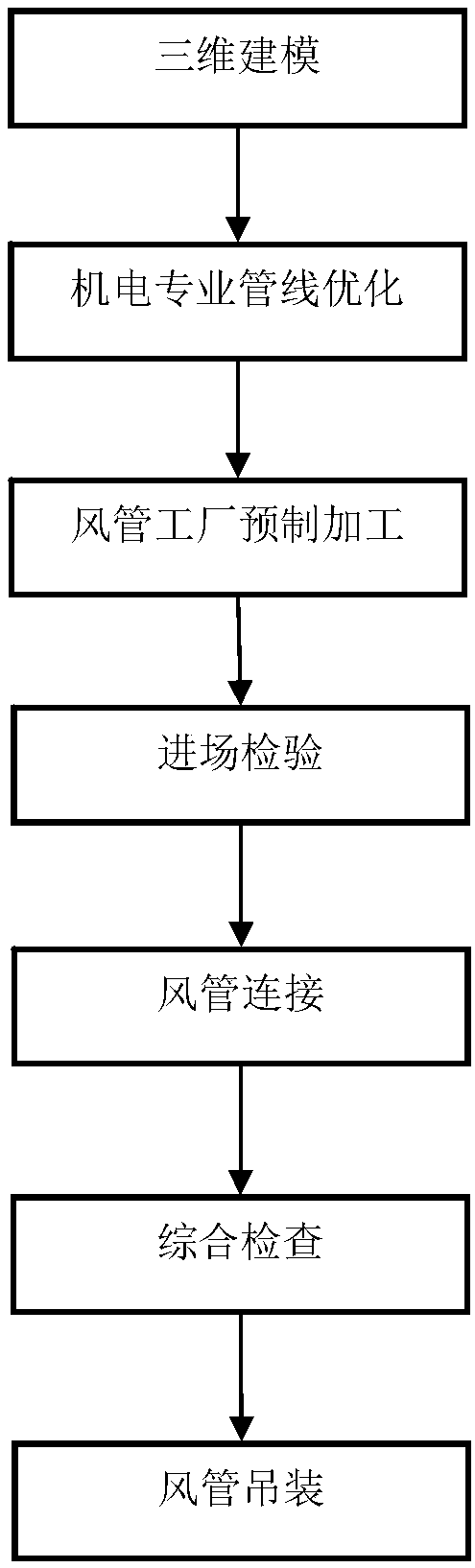

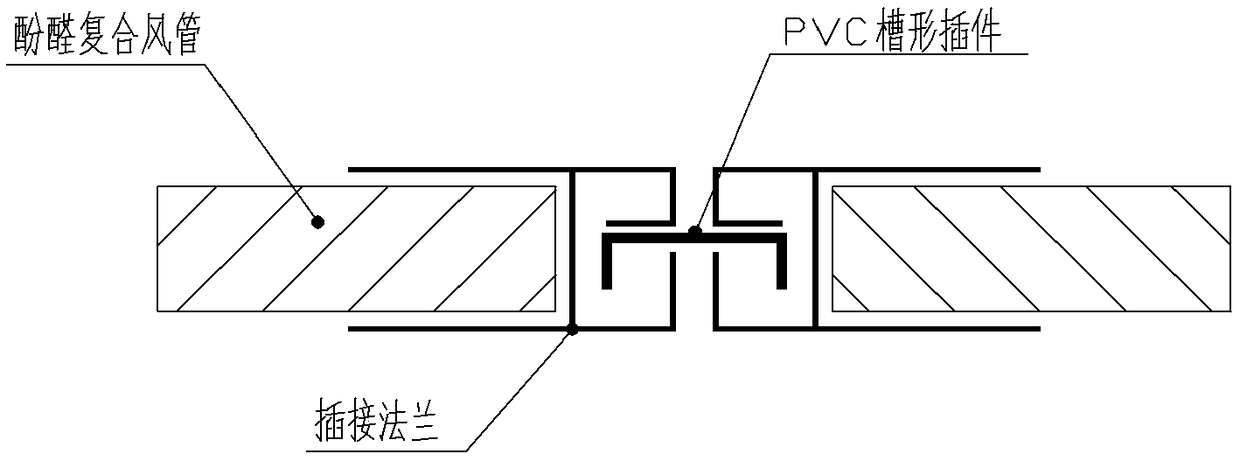

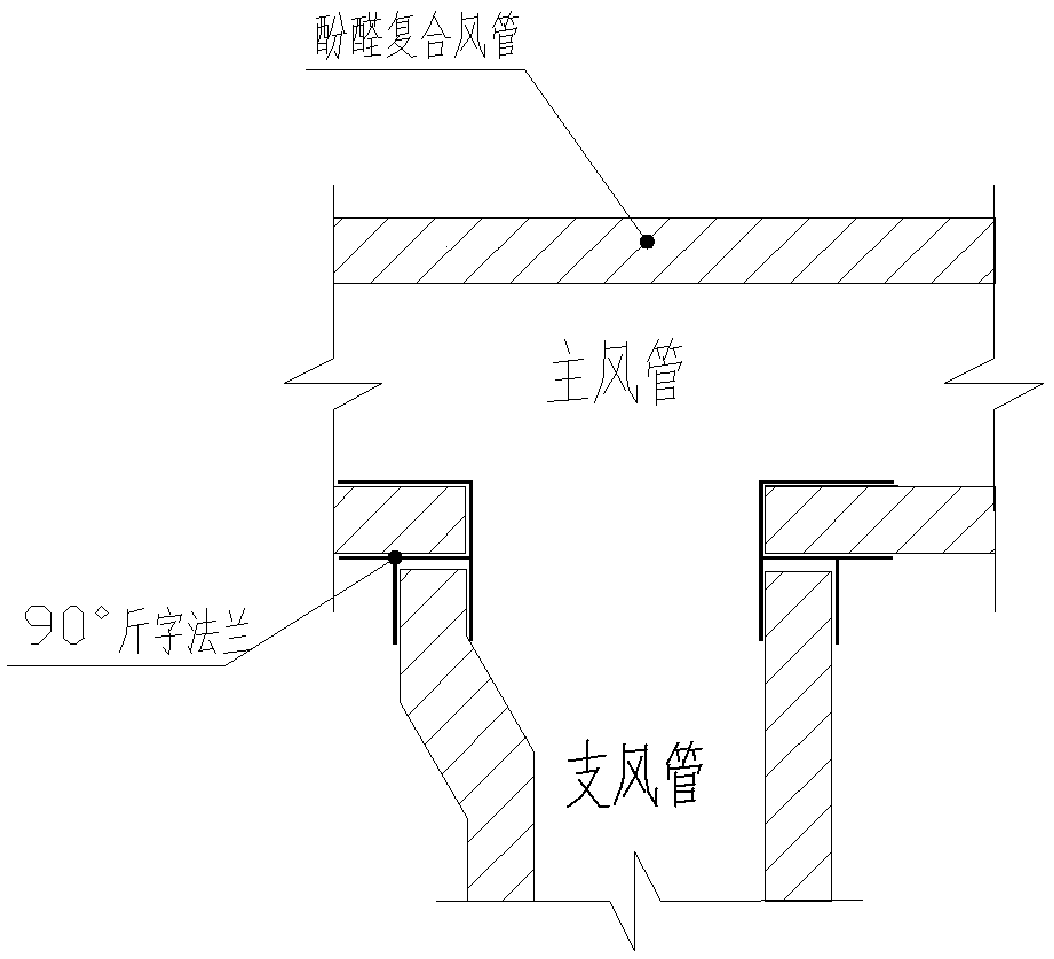

Method used

Image

Examples

Embodiment

[0048] The embodiment of the present invention is the construction of the testing laboratory and administrative building of Guangzhou Huagong Motor Vehicle Testing Technology Co., Ltd. (Phase I). The total land area of the project is about 22012㎡, the total building area is about 30848.3㎡, and the building base area is 5049㎡. The main functions are administrative office, motor vehicle inspection, restaurant, etc. The concrete frame-shear wall structure is adopted, and the building category is a high-rise factory building (category D, E), and the fire resistance and waterproof rating of the building are both first class. There is 1 floor underground with a height of 5.250m, 11 floors above ground, the height of the first floor to the second floor is 4.0m, the standard floor is 4.2m, the total building height is 50.0m, and the excavation depth of the basement is about 4.35m.

[0049] The air-conditioning area of this project is about 17,380 square meters. Functional rooms su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com