A five-axis CNC machining instruction point interpolation method based on tool attitude control

A technology of attitude control and machining instructions, applied in the field of five-axis CNC machining instruction point interpolation based on tool attitude control, can solve problems such as errors, affecting the smoothness of the machining surface, and increasing the burden of data transmission, so as to improve the smoothness of the machining surface , Avoid nonlinear errors, improve the effect of machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to make the objects, technical solutions and advantages of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments. DETAILED DESCRIPTION OF THE INVENTION The present invention is not intended to limit the invention.

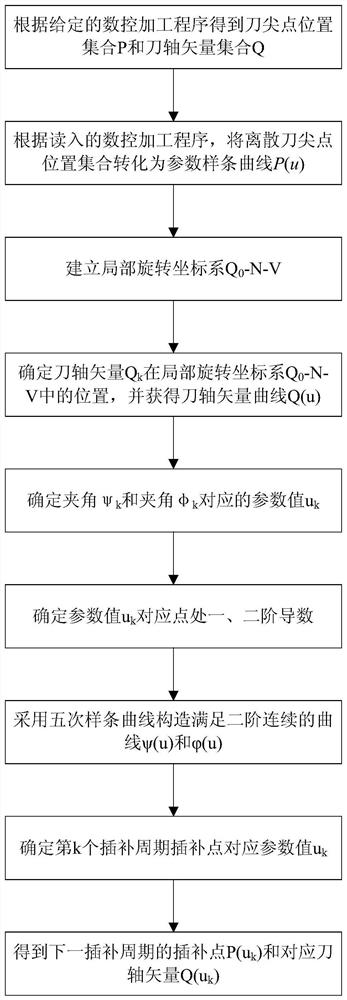

[0049] A five-axis CNC machining instruction point interpolation method based on tool attitude control, figure 1 As shown, the specific method is as follows:

[0050] Step 1: Depending on the machining requirements, use the five-axis CNC machining program to get the knife pin point set P = {P by the given CNC machining program k | P k (P) xk , P yk , P zk ) And p xk , P yk , P zk ∈R, k = 0, ..., n} and knife shaft vector set Q = {Q k | Q k = (Q xk Q yk Q zk ), | Q k | = 1, k = 0, ..., n};

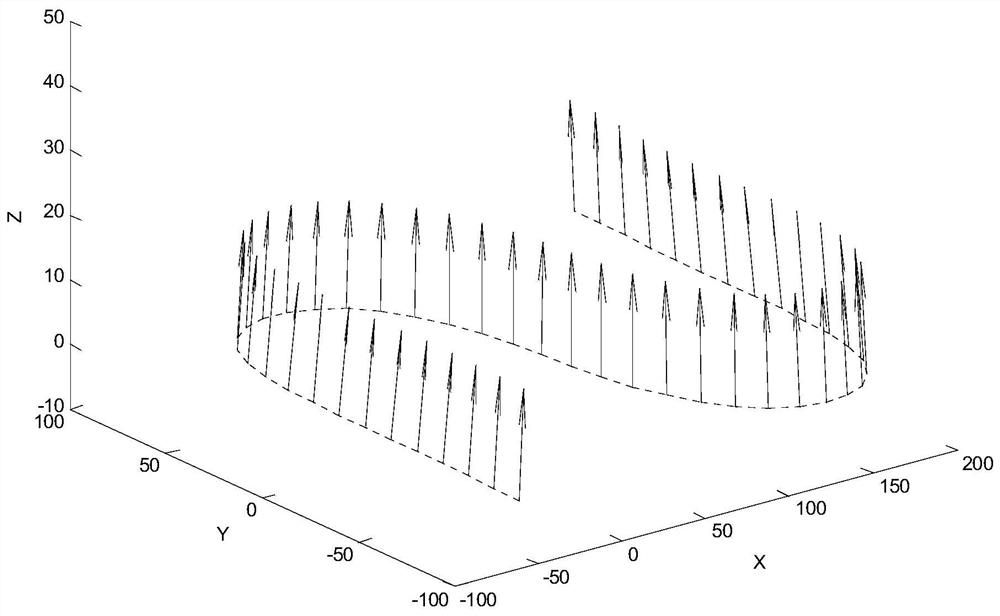

[0051] In the present embodiment, the CNC machining process formed by the knife shaft vector programming is obtained by the tool tip point position set P and the kni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com