Device and method for single-camera repetitive visual detection of tobacco rods

A detection device, single camera technology, applied in measurement devices, optical testing flaws/defects, instruments, etc., can solve problems such as unreliability, qualified, inaccurate detection results, etc., to improve accuracy and reliability, and reduce false rejections ratio, the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

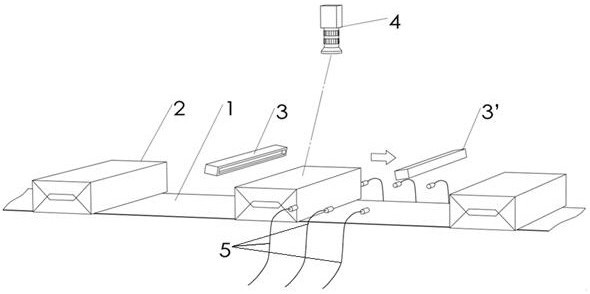

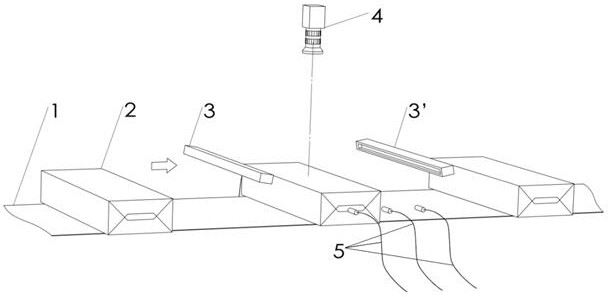

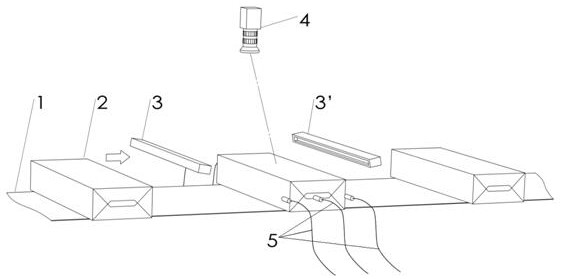

[0054] Such as Figure 1-5 As shown, the single-camera repetitive visual detection device for tobacco rods includes a conveyor belt 1, a light source group, a camera 4, a repeated trigger optical fiber group 5, a controller 6, and a graphics processor 7. The conveyor belt 1 transports tobacco rods 2 moving at a constant speed, a camera 4 is installed above the conveyor belt 1, and a light source group for providing illumination to the camera 4 is also installed above the conveyor belt 1. The light source group includes a front light source 3 and a rear light source 3', and the front light source 3 and The rear light sources 3 ′ are respectively installed on the front and rear sides below the camera 4 . On both sides of the conveyor belt 1 and below the camera 4, a repeat trigger fiber optic group 5 is installed. The repeat trigger fiber optic group 5 consists of two or more fiber optic sensors. The number and spacing of the fiber optic sensors must meet the shooting time of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com