Micro-fluidic chip use method capable of combining with cuvette

A technology of microfluidic chips and cuvettes, applied in chemical instruments and methods, laboratory containers, and analysis by chemical reactions of materials, etc., to avoid adhesion, avoid pollution, and reduce waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

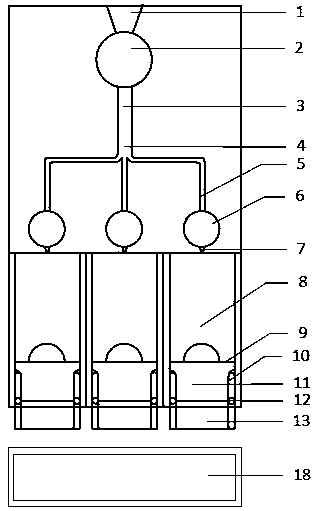

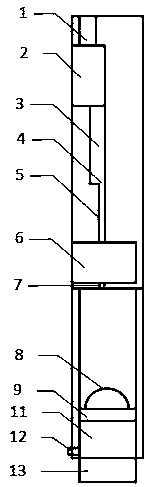

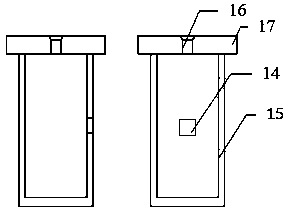

[0036] refer to figure 1 and Figure 9 The shape and structure of a microfluidic chip used in combination with a cuvette is composed of three parts: a split flow area, a mixing area, and a liquid outlet area. It is characterized in that: the whole chip is in the shape of a cuboid slab. Arranged vertically according to the longest side of the cuboid, and sequentially process various functional components of the diversion area, mixing area, and liquid outlet area from the top.

[0037] The split area includes the top sample inlet 1 , the cylindrical sample storage tank 2 below the sample inlet 1 , and the main channel 3 communicating with the sample storage tank 2 , and also includes a liquid separation port 4 and a sample separation channel 5 . The main channel 3 is connected to three sample distribution channels 5 through the liquid distribution port 4, and the three sample distribution channels 5 are arranged parallel, vertical and equidistant after liquid separation at the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com