Front-mounted type precombustion chamber of biomass direct combustion boiler

A pre-combustion chamber and front-mounted technology, which is applied in the direction of solid fuel combustion, grate, combustion methods, etc., can solve the problems of coking of ash and slag, high carbon content of fly ash, high ash content, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

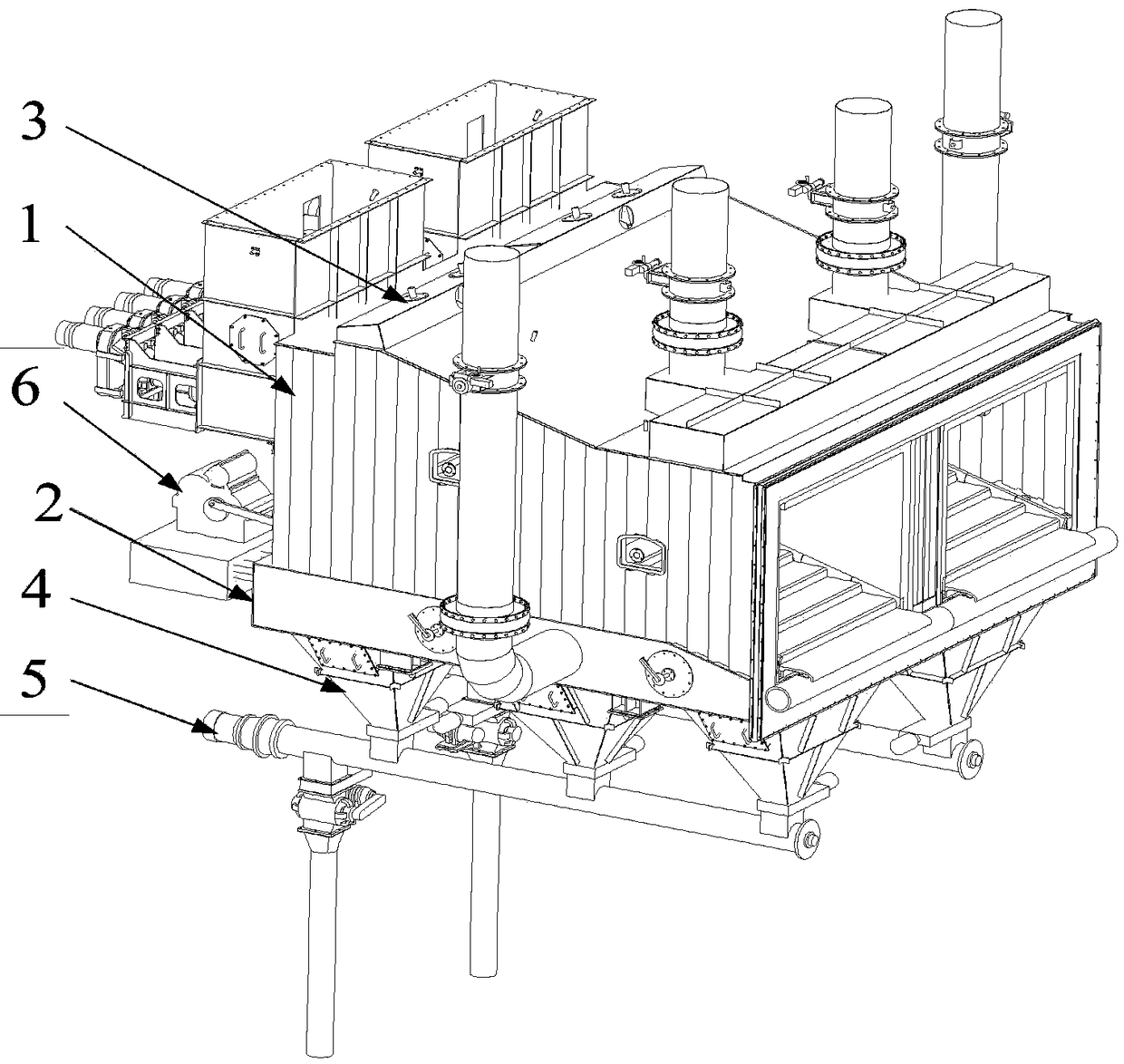

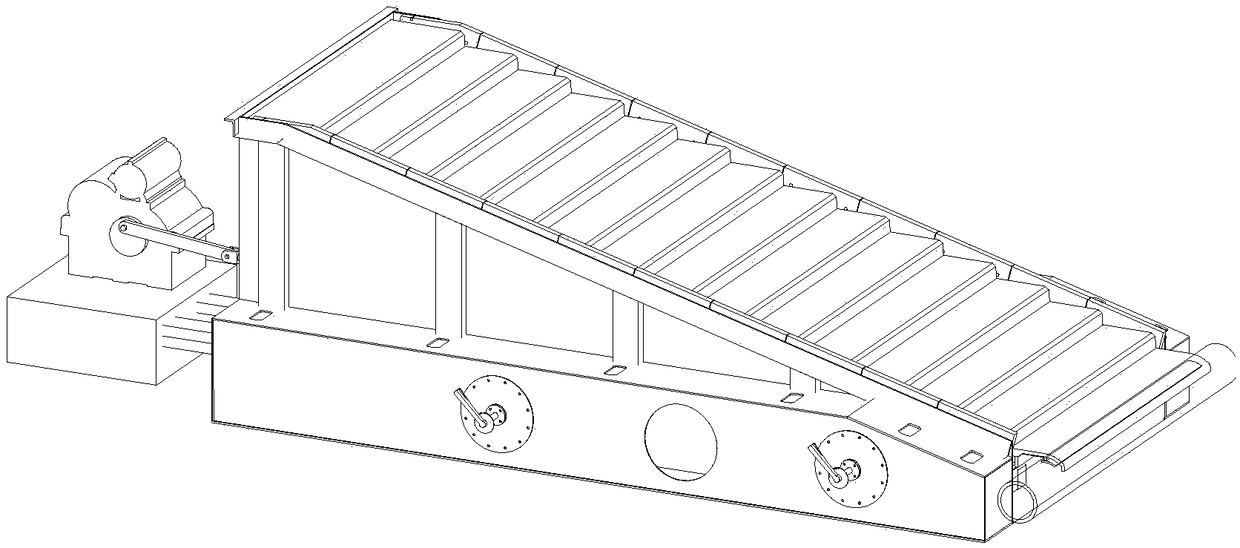

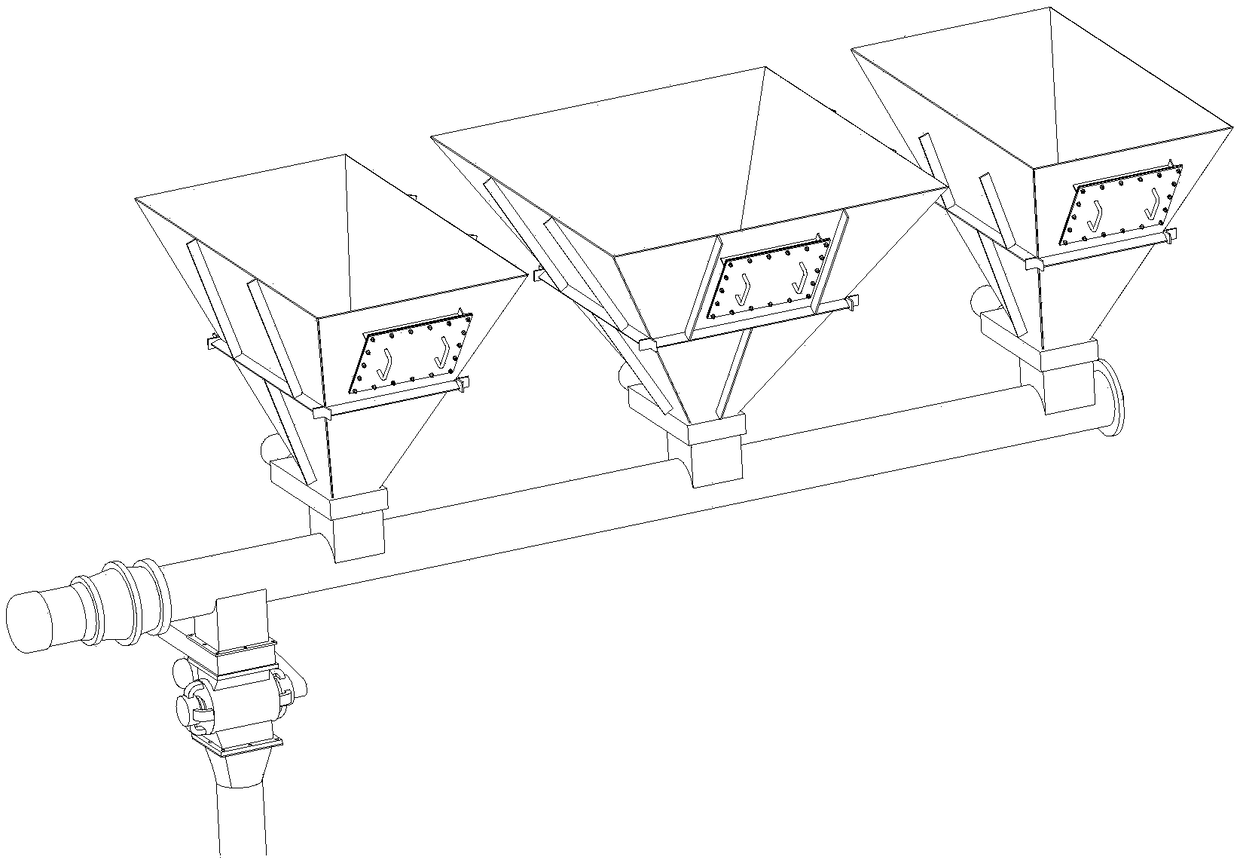

[0017] Such as Figure 1-3 , the embodiment of the present invention provides a front-mounted pre-combustion chamber of a biomass direct-fired boiler, including a pre-chamber adiabatic furnace 1, a reciprocating grate 2, a combustion-supporting burner 3, an ash hopper 4, a grate driving device 5 and an unloading chamber. Ash device 6; the reciprocating grate is located below the adiabatic hearth of the pre-combustion chamber, and the combustion-supporting burner is arranged on the upper part of the adiabatic furnace of the pre-combustion chamber, which is used for ignition and supplementary combustion during normal operation. The reciprocating grate includes multiple Each air chamber is provided with a corresponding ash discharge hopper, and the lower end of each ash discharge hopper is connected to the ash unloading...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com