A kind of method utilizing xylose as raw material to produce ethylene glycol and glycolic acid

A technology of xylose acid and ethylene glycol, which is applied in the field of bioengineering to achieve the effects of high production intensity, high substrate conversion rate, and tenacious growth of bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

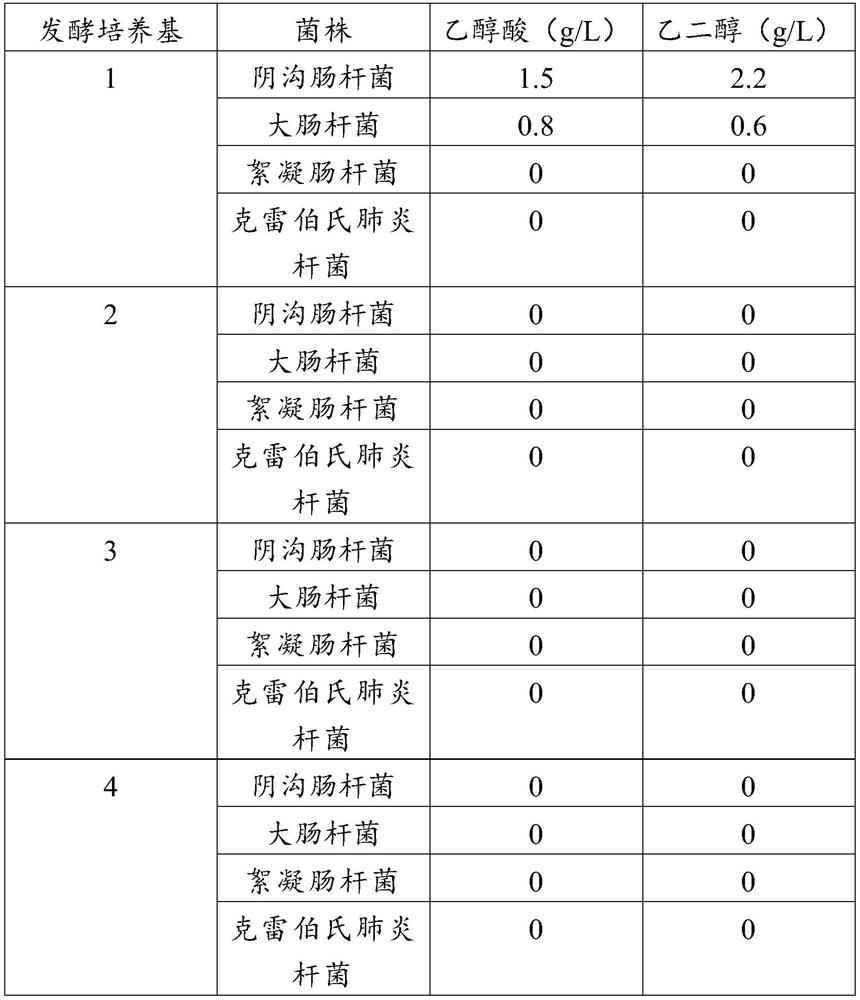

Examples

Embodiment 1

[0027] Production of xylonic acid from xylose by conversion of xylose by Lebsiella pneumoniae.

[0028] Klebsiella pneumoniae was inoculated into a 250mL Erlenmeyer flask containing 50mL of seed medium, and the shaker cabinet was rotated at 200 rpm and kept at a constant temperature of 35°C for seed cultivation.

[0029] The components of the seed medium are: peptone 10g / L, yeast extract 5g / L, sodium chloride 5g / L.

[0030] The composition of the fermentation medium is: xylose 50g / L, corn steep liquor 50g / L, potassium dihydrogen phosphate 3g / L, dipotassium hydrogen phosphate 2g / L, calcium chloride 1g / L, magnesium sulfate 4g / L.

[0031] After the seeds were cultured for 12 hours, they were inoculated into a 5L fermenter with 3L of fermentation medium, and the dissolved oxygen concentration during the fermentation process was kept greater than 1% of the saturated dissolved oxygen concentration. The fermentation temperature was 35°C, the pH was controlled at 6, and cultured for 5...

Embodiment 2

[0033] Glucose oxidase and catalase are used as composite catalysts to catalyze the conversion of xylose to produce xylonic acid.

[0034] Glucose oxidase was added to the 5L reaction at an enzyme activity ratio of 2000 units per kilogram of xylose, and catalase was contained in 3L of 10g / L xylose solution. The reaction temperature was 25°C, the conversion process was ventilated with air and stirred, the pH value of the conversion process was maintained at 4.5 by using ammonia water, and the conversion was completed in 5 hours to obtain 10 g / L xylonic acid.

[0035] The obtained xylonic acid solution is used as raw material for the subsequent production of glycolic acid and ethylene glycol.

Embodiment 3

[0037] Glucose oxidase and catalase are used as composite catalysts to catalyze the conversion of xylose to produce xylonic acid. Glucose oxidase and catalase are industrial grade products.

[0038] Glucose oxidase is added to the 5L reaction at an enzyme activity ratio of 50,000 units per kilogram of xylose, and catalase is contained in 2L of 500g / L xylose solution. The reaction temperature was 50°C, the conversion process was aired and stirred, and the pH value of the conversion process was maintained at 7 by using sodium hydroxide solution. After 150 hours of conversion, a 480 g / L xylonic acid solution was obtained.

[0039] The obtained xylonic acid solution is used as raw material for the subsequent production of glycolic acid and ethylene glycol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com