Liquid fuel saccharification production device and method for electric power

A technology for liquid fuel and production equipment, applied in the direction of liquid production bioreactors, biochemical cleaning equipment, biochemical equipment and methods, etc., can solve the problems of high impurities, increased cost and investment, etc., to increase solid content and increase production Good yield and purity, anti-scaling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

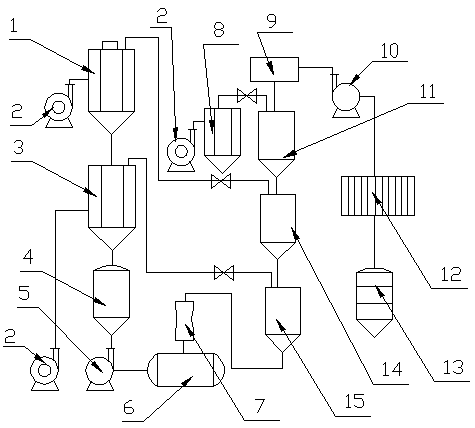

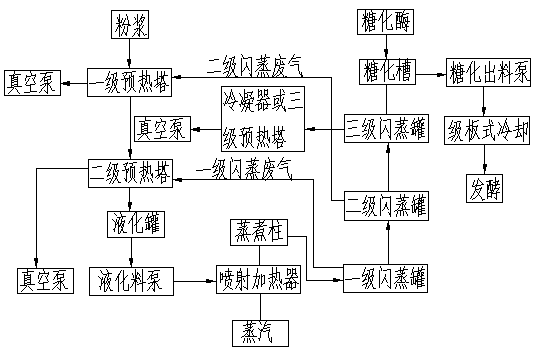

[0032] refer to figure 1 , this embodiment provides a liquid fuel liquid saccharification production device for electric power, including a liquefaction mechanism, a cooking mechanism connected to the liquefaction mechanism, a saccharification tank 9 connected to the cooking mechanism, and a saccharification tank 9 connected A cooling mechanism, a fermenter 13 connected to the cooling mechanism;

[0033]The liquefaction mechanism includes a primary preheating tower 1, a secondary preheating tower 3, and a liquefaction tank 4 connected to the secondary preheating tower in sequence; A heater 6 connected to a delivery pipeline provided with a liquefied material pump 5, a cooking column 7 connected to the heater 6, a primary flash tank 15 sequentially connected to the cooking column 7, a secondary flash Steam tank 14, three-stage flash tank 11.

[0034] The primary preheating tower 1 in the liquefaction mechanism is provided with a feed port, and the heater 6 is provided with a ...

Embodiment 2

[0038] refer to figure 1 , this embodiment provides a liquid fuel liquid saccharification production device for electric power. The difference from Embodiment 1 is that in this embodiment, the heater 6 is a spray heater to save steam, and the gas heat exchange module 8 is a condenser, and the remaining high-temperature steam output from the three-stage flash tank 11 is sent into the condenser to be condensed into a liquid with higher pressure, and the vacuum pump 2 extracts non-condensable gas to maintain the vacuum degree.

Embodiment 3

[0040] refer to figure 1 , this embodiment provides a liquid fuel liquid saccharification production device for electric power. The difference from Embodiment 2 is that in this embodiment, the cooling mechanism 12 is a wide-channel plate heat exchanger, which improves heat transfer efficiency and saves Energy, compact structure, small footprint.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com