Production process of environment-friendly chalk

A production process and technology of chalk, which is applied to pencil lead, household utensils, applications, etc. It can solve the problems of insufficient chalk production process, dust or toxic solvents in chalk, and difficulty in erasing, so as to achieve easy writing and moisturizing, and avoid dust Floating, fine powder effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The present invention is made of raw materials in parts by weight, including: 30-35 parts of titanium dioxide, 40-80 parts of gypsum powder, 2-10 parts of ceramic powder, 2-5 parts of palm wax; 5-7 parts of paraffin wax; castor oil 5-8 parts; 1-3 parts of fatty acid amide, 10-15 parts of fatty alcohol polyoxyethylene ether, 10-15 parts of polyethylene glycol, 1-2 parts of barium sulfate, 5-7 parts of butyl oleate, 1-2 parts of acid dye, 100-160 parts of water.

[0024] By adopting the chalk that the raw material in the above-mentioned embodiment is made, because there is palm wax, castor oil to add the chalk making raw material of palm wax, castor oil, fatty acid amide, fatty alcohol polyoxyethylene ether composition, due to the palm wax, castor oil The viscous and lubricating effects make the manufactured environmentally-friendly chalk soft, easy to write and moisturize, and avoid dust from chalk during writing.

Embodiment 2

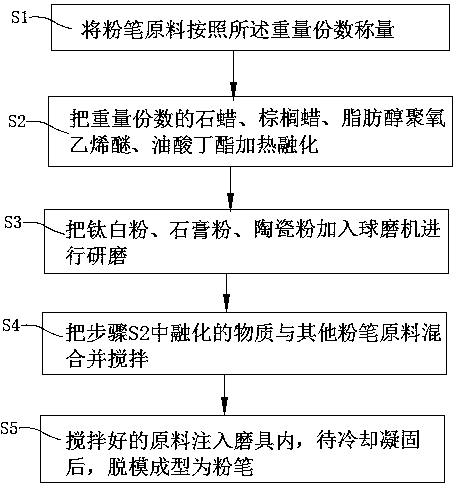

[0026] like figure 1 Shown, in the figure S1, S2, S3, S4, S5 correspond respectively following steps (1), (2), (3), (4), (5) the environmental protection chalk production technology of the present invention comprises the following steps: (1) Weigh the chalk raw materials according to the parts by weight; (2) heat and melt the paraffin wax, palm wax, fatty alcohol polyoxyethylene ether and butyl oleate in the parts by weight; (3) put The titanium dioxide, gypsum powder, and ceramic powder are added into a ball mill for grinding; (4) the material melted in step (2) is mixed with the titanium dioxide, gypsum powder, ceramic powder, castor oil, and fatty acid amide in the stated parts by weight , polyethylene glycol, barium sulfate, and acid dyes, and stir with a stirrer; (4) Pour the stirred raw materials into the mold, and after cooling and solidifying, demould and form chalk.

[0027] What needs to be explained here is that the ball mill used in the present invention is a comm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com